Regenerated ink box chip, regenerated ink box and production process for regenerated ink box

An ink cartridge chip and production process technology, applied in the fields of regenerated ink cartridge chips, regenerated ink cartridges and their production processes, can solve problems affecting the recycling of ink cartridges, short circuits, etc., so as to reduce the risk of virtual welding, improve electrical connection strength, and avoid welding problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

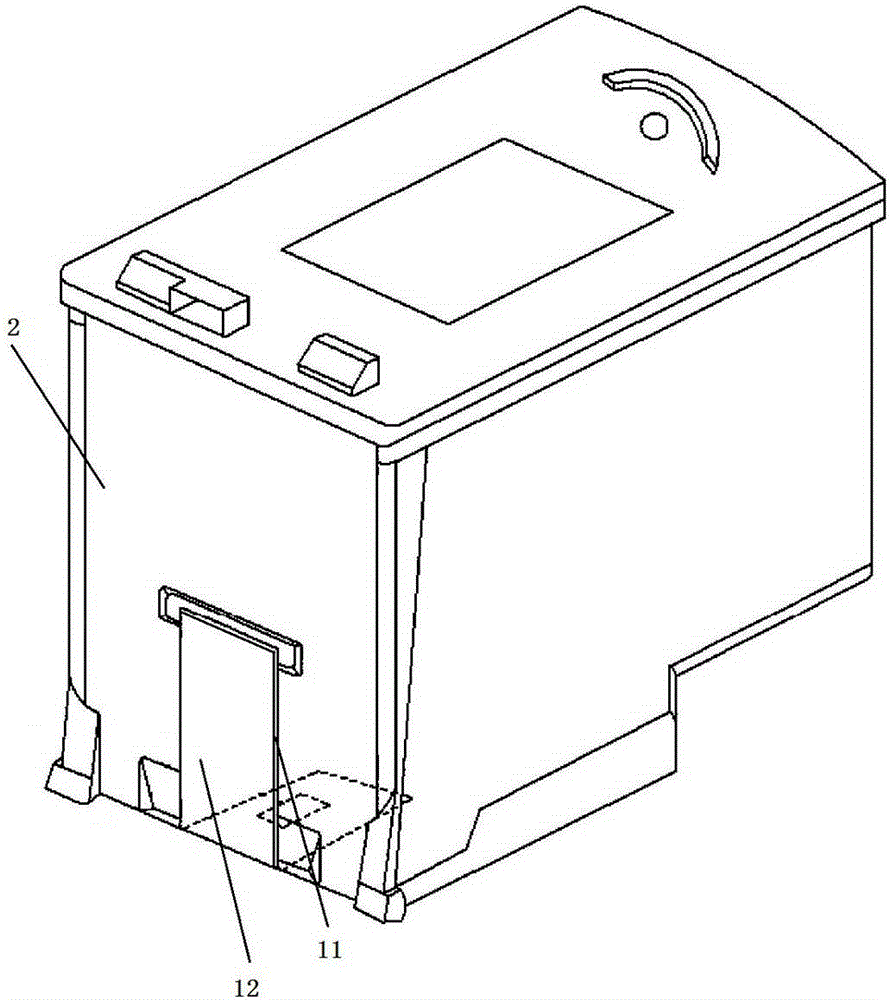

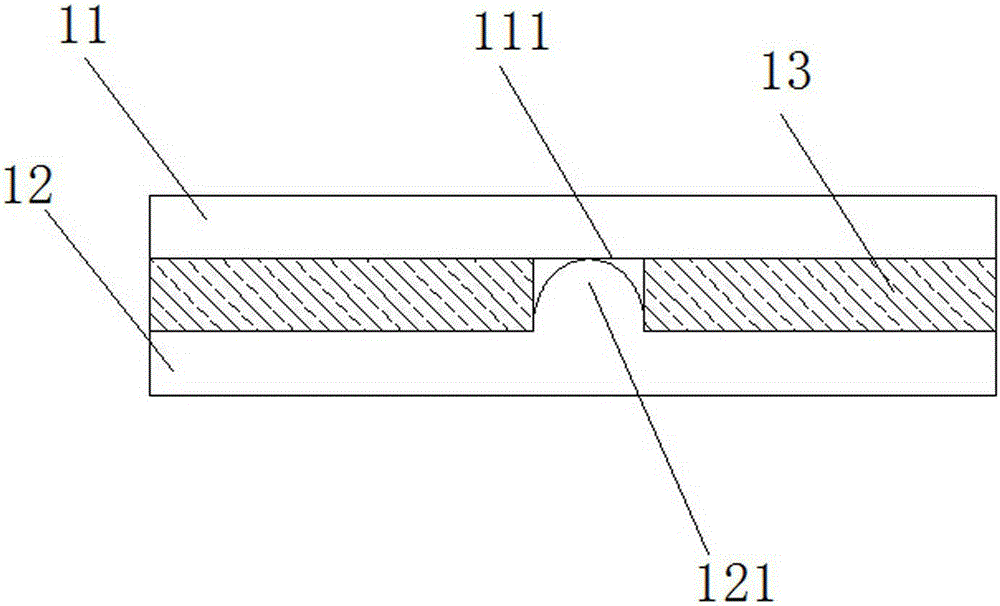

[0049] A regenerated ink cartridge includes a regenerated ink cartridge chip and a container for containing ink. Among them, the structure of the regenerated ink cartridge chip is as follows: figure 2 , including an original chip 11, a repair chip 12, an adhesive layer 13 that is arranged between the original chip 11 and the repair chip 12 and connects the original chip 11 and the repair chip 12; the tin point 121 of the repair chip 12 passes through the adhesive layer 13 and the original Contacts 111 of the chip 11 are contacted. The regenerated ink cartridge chip is installed on the container 2 of the ink cartridge, and the repair chip 12 of the regenerated ink cartridge chip is arranged on the outside of the original chip 11 (such as figure 1 ), so that the original chip 11 is connected to the repair chip 12 and the outer surface of the container 2 . In order to ensure good contact between the repaired chip 12 and the original chip 11 , the thickness of the tin dots 121 ...

Embodiment 2

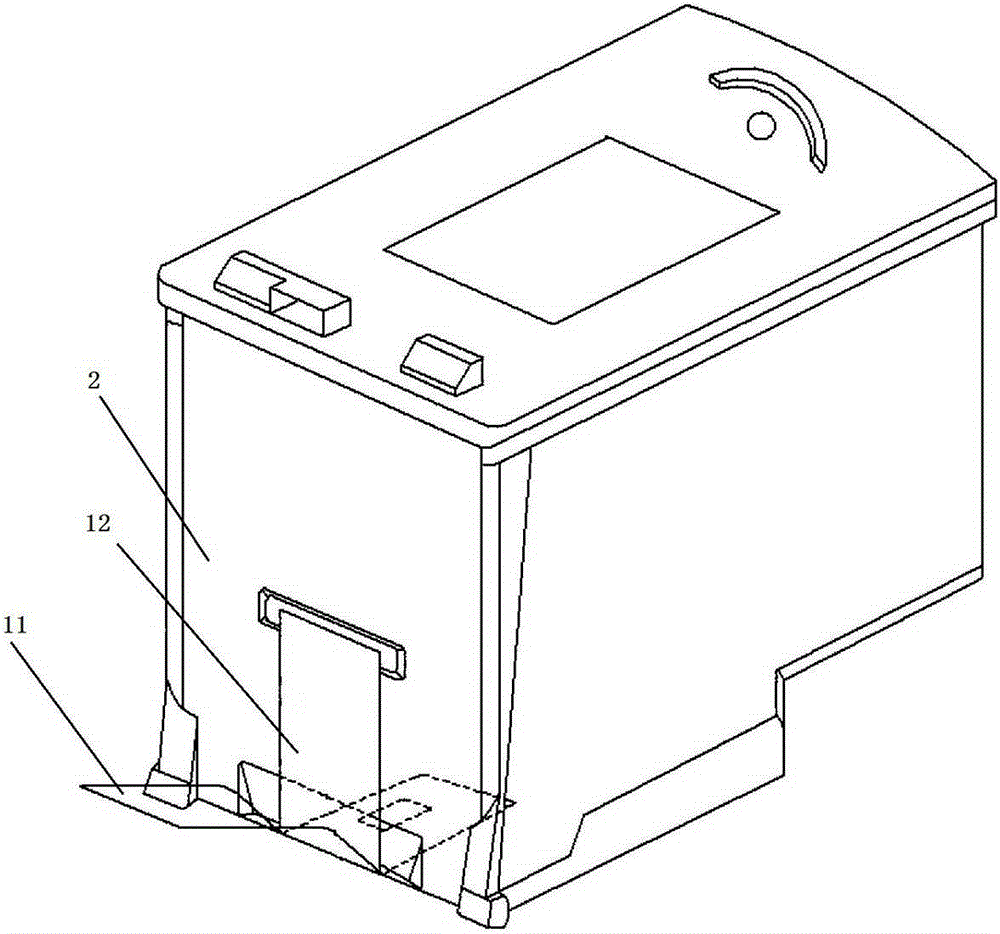

[0071] Repair chip 12 also can be arranged on former chip 11 inner side (as image 3 ), so that the repair chip 12 is connected to the original chip 11 and the outer surface of the container 2 . In order to prevent other contacts of the original chip 11 from accidentally connecting, improve the safety of the circuit, and prevent interference; ensure that even if the adhesive layer 13 fails, the original chip 11 and the repaired chip 12 are misplaced, and it is not easy to cause a short circuit to cause the chip to break. The phenomenon of burning out. An insulating film 14 can be arranged on the back side of the original chip 11, and the tin point 121 of the repair chip 12 passes through the adhesive layer 13 and the insulating film 14 to contact with the contact 111 of the original chip 11 (such as Figure 4 ). In order to ensure good contact between the repaired chip 12 and the original chip 11 , the thickness of the tin point 121 needs to be the sum of the thicknesses of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com