Wear-resisting ball surface treating device

A surface treatment device and technology of wear-resistant balls, which are applied in the field of wear-resistant balls, can solve problems such as increased dust, unremoved rust, and polluted working environment, and achieve the effects of improving work efficiency, reasonable structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

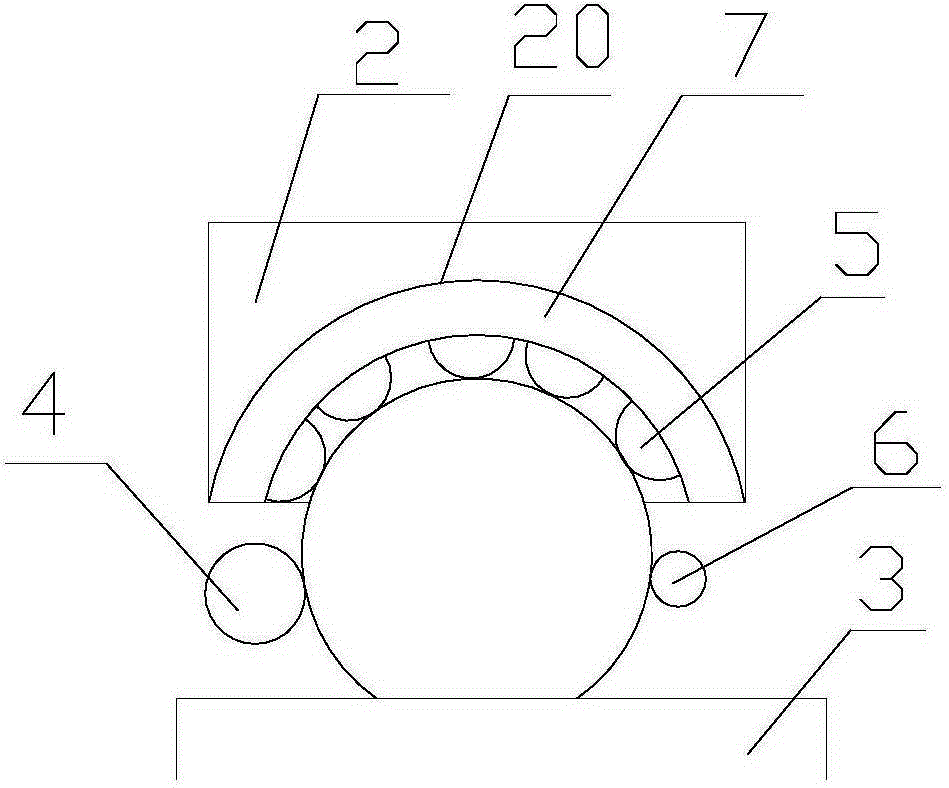

[0021] refer to figure 1 , figure 2 , a wear-resistant ball surface treatment device proposed by the present invention, comprising: a bracket 1, a rust removal structure 2, a plurality of first rollers 3, a second roller 4, a first driving mechanism and a second driving mechanism;

[0022] A plurality of first rollers 3 are installed on the support 1, and are arranged parallel to each other on an inclined plane to form a transport track 30. There is a gap between adjacent first rollers 3, so that the sundries on the transport track 30 can pass through the gap. drop in.

[0023] The first driving mechanism is respectively connected with the first roller 3 and drives it to rotate around the central axis; the wear-resistant ball A on the transport track 30 rolls from the high end to the low end, and the rotation direction of the first roller 3 moves with the wear-resistant ball A in the opposite direction. In this way, the wear-resistant ball A is under the action of gravity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com