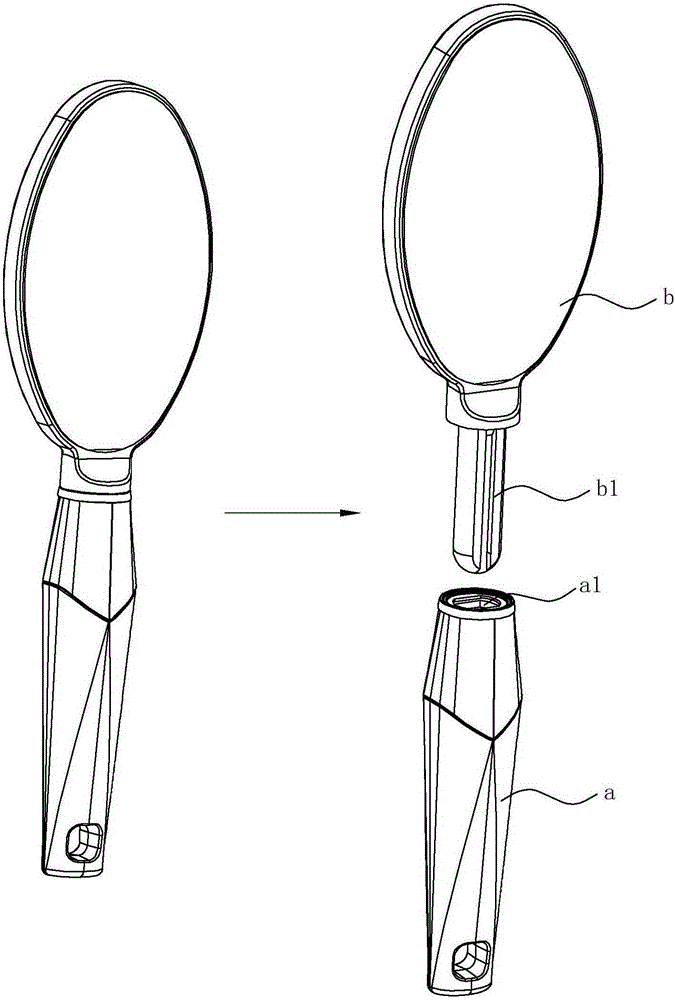

Semi-automatic comb assembler

A semi-automatic and assembly machine technology, applied in the direction of mechanical equipment, other manufacturing equipment/tools, material gluing, etc., can solve problems such as low pass rate, low production efficiency, instability, etc., to reduce the influence of human factors and reduce production cost, and the effect of increasing production profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

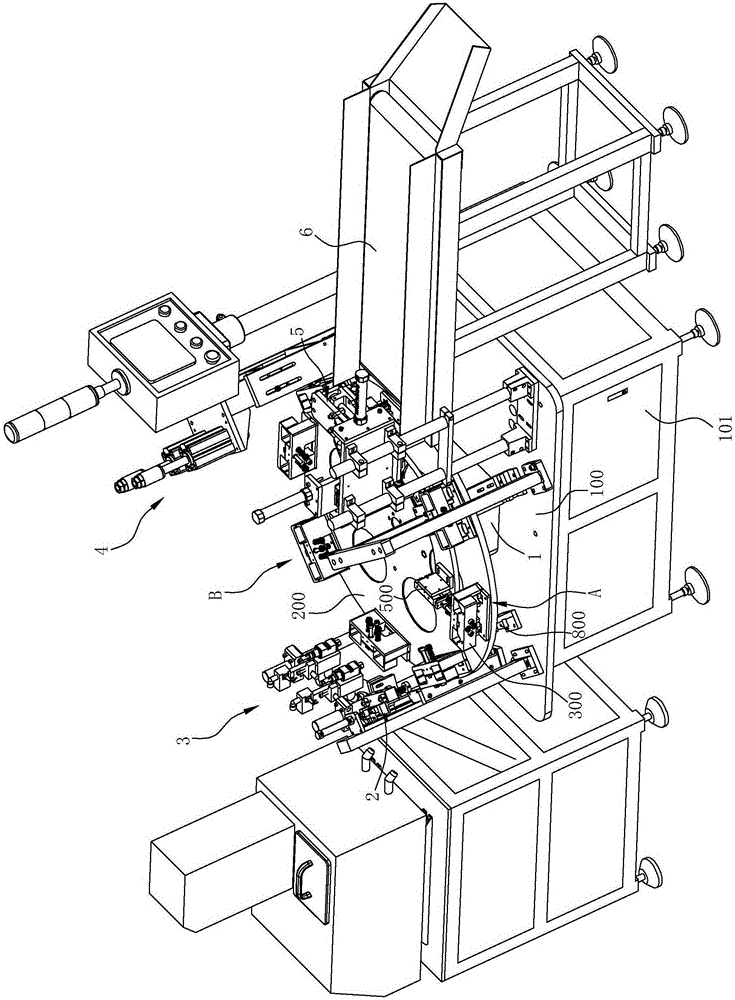

[0050] Such as figure 2 , 3 As shown, the semi-automatic comb assembly machine in this embodiment includes an assembly platform 100 , a turntable 200 , a first drive mechanism 1 , a detection mechanism 2 , a dispensing mechanism 3 , a pressing mechanism 4 and a finished product removal mechanism 5 . The assembly platform 100 is supported on the ground by a mounting frame 101 . The turntable 200 is disc-shaped and rotatably arranged on the assembly platform 100. The edge of the turntable 200 has a plurality of operating stations arranged at intervals along the circumferential direction, and each operating station is respectively provided with a comb handle for clamping the comb handle. Positioning mechanism 300 . The bottom of the turntable 200 is supported on the assembly platform 100 by four support arms 800 arranged at intervals, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com