A heating method and device for raw sand

A heating method and raw sand technology, which are applied in metal processing equipment, machinery for cleaning/processing of casting materials, casting molding equipment, etc., can solve the problem of low temperature of raw sand, avoid excessively low temperature and improve product quality , the effect of increasing the speed of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

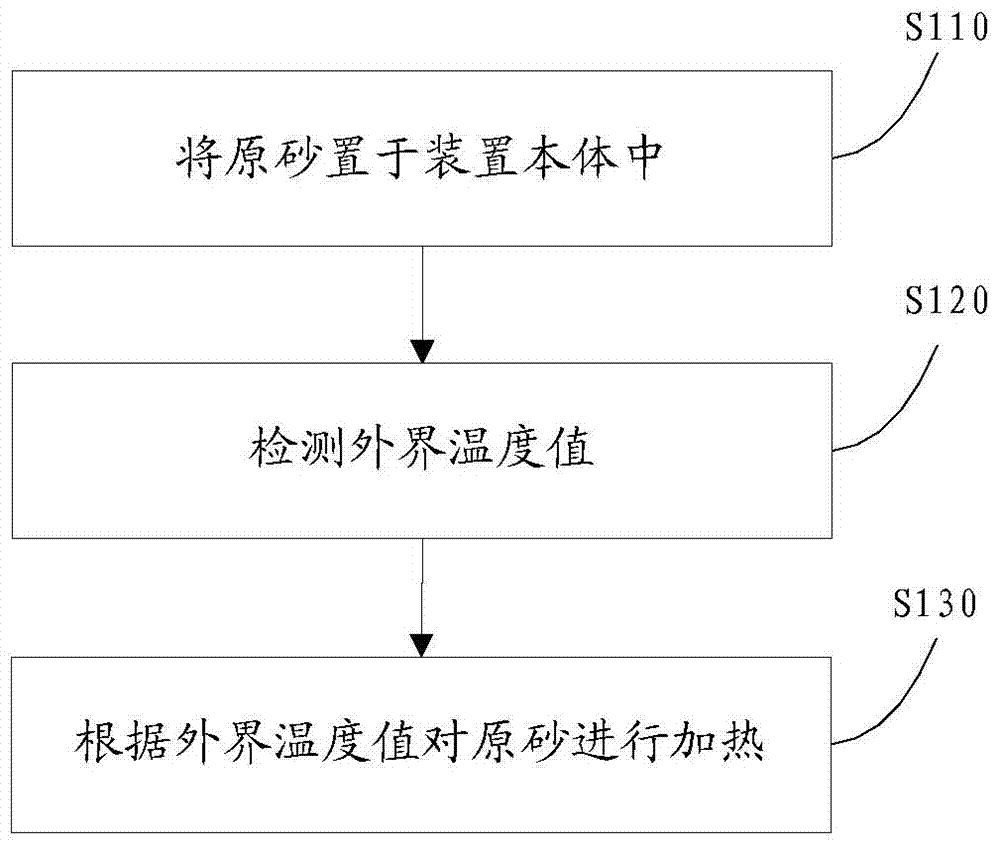

[0048] see figure 1 , the heating method for raw sand provided by the embodiment of the present invention includes:

[0049] Step S110: placing the raw sand in the device body;

[0050] Step S120: Detect the external temperature value;

[0051] Step S130: heating the raw sand according to the external temperature value;

[0052] in,

[0053] When the outside temperature is between 0 and 10°C, the temperature of the raw sand in the middle of the device body is 2-4°C higher than that of the rest of the raw sand;

[0054] When the outside temperature is between -10 and 0°C, the temperature of the raw sand in the middle of the device body is 3-5°C higher than that of the rest of the raw sand;

[0055] When the outside temperature is between -20 and -11°C, the temperature of the raw sand in the middle of the device body is 3-6°C higher than that of the rest of the raw sand;

[0056] When the outside temperature is lower than -21°C, the temperature of the raw sand in the middle o...

Embodiment 2

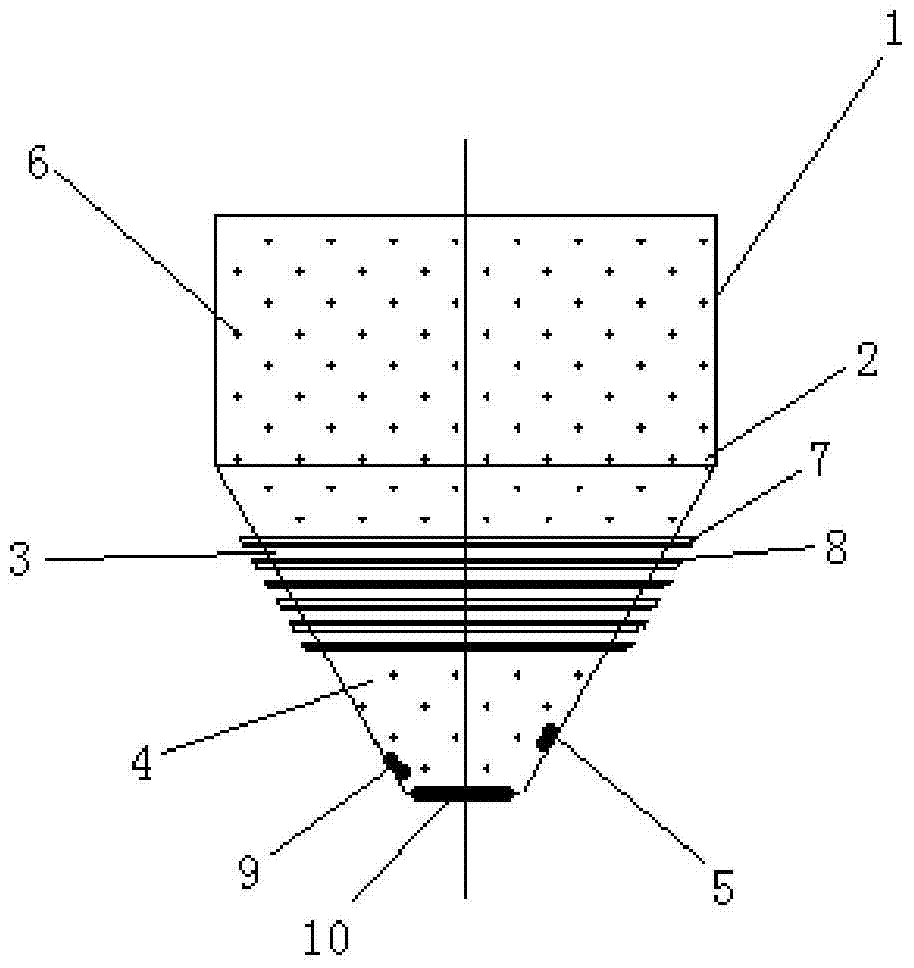

[0065] see figure 2 , the heating device for raw sand provided by the embodiment of the present invention, the device corresponds to the above method, including: a device body and a heating mechanism; the heating mechanism is arranged in the device body; when the raw sand 6 enters the device body, the heating mechanism according to The external temperature value heats the raw sand 6 respectively.

[0066] in,

[0067] When the external temperature is between 0 and 10°C, the temperature of the raw sand in the middle of the device body is 2-4°C higher than that of the rest of the raw sand;

[0068] When the external temperature is between -10 and 0°C, the temperature of the raw sand in the middle of the device body is 3-5°C higher than that of the rest of the raw sand;

[0069] When the outside temperature is between -20 and -11°C, the temperature of the raw sand in the middle of the device body is 3-6°C higher than that of the rest of the raw sand;

[0070] When the externa...

Embodiment 3

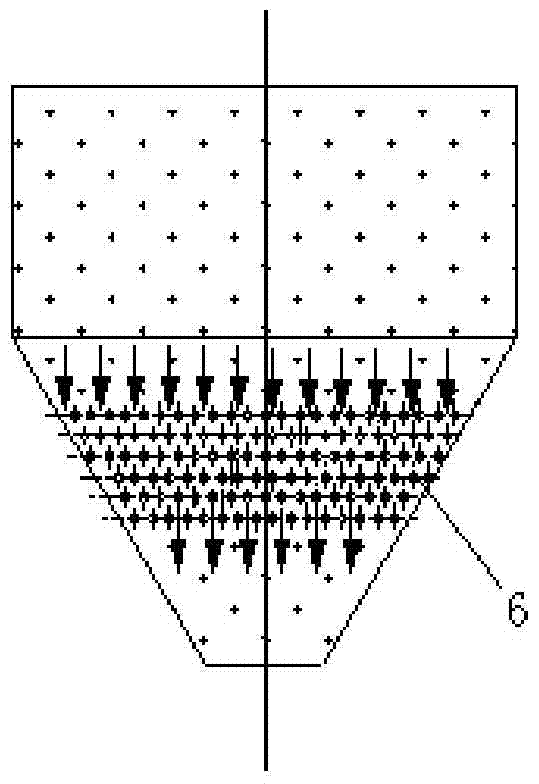

[0081] see image 3 , when the heating device provided by the embodiment of the present invention is in use, the raw sand 6 is added to the sand bucket 1; the raw sand 6 passes through the sand adding section 2 and reaches the heating section 3. The raw sand 6 passes through the heating pipe 7 from top to bottom due to its own weight, and the heating pipe 7 heats the raw sand 6 at each position in the device body respectively. The heated raw sand 6 falls to the storage section 4 again, and can be output from the storage section 4 to enter the next process. Wherein, by adjusting the heating temperature and the discharge flow rate of the raw sand 6, the temperature of the discharged raw sand 6 reaches the target temperature. What needs to be explained here is that multiple temperature measuring points are set in the storage section 4 to monitor the sand temperature in good time, and the temperature of the heating wire 8 can be adjusted according to the sand temperature so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com