Separation method of copper-sulphur ore rich in pyrrhotite and pyrite

A technology of pyrrhotite and mineral processing method, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve problems such as unfavorable environmental protection, non-recycling of tailings water, etc., achieve low cost, improve mineral processing index, The effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

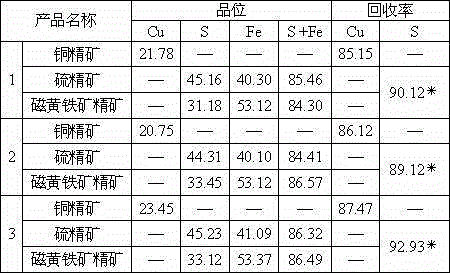

[0020] Copper-sulfur ore with 0.60% Cu, 12.69% pyrrhotite and 28.24% pyrite.

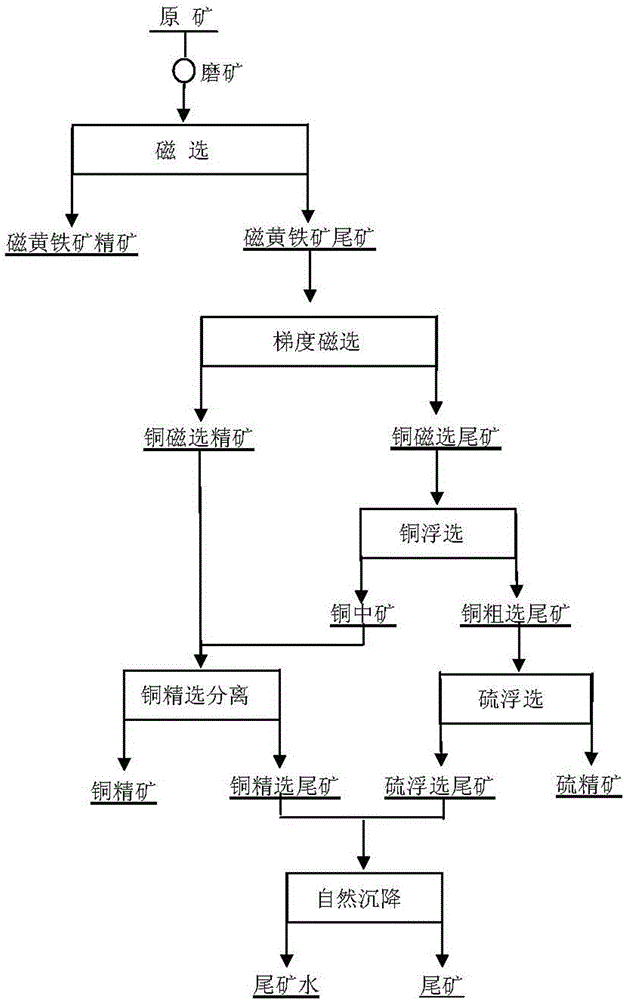

[0021] 1) Raw ore is crushed and ground to a particle size of -0.074mm, accounting for 65%;

[0022] 2) Magnetic separation: the magnetic field strength is 0.15T to obtain pyrrhotite concentrate and pyrrhotite tailings;

[0023] 3) Gradient magnetic separation: Pyrrhotite tailings undergo gradient magnetic separation with a magnetic field strength of 0.9T to obtain copper magnetic separation concentrate and copper magnetic separation tailings;

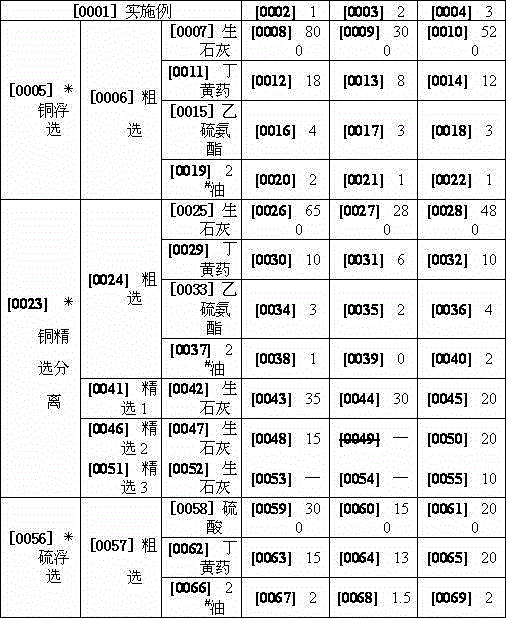

[0024] 4) Copper flotation: Copper flotation for copper magnetic separation tailings, ① 1 roughing: add 800 g / ton of quicklime, 18 g / ton of butyl xanthate, 4 g / ton of thiocarbamate to the copper magnetic separation tailings tons and 2 # Oil 2 g / ton, stirring for 3 minutes; ②1 selection: without adding chemicals, stirring for 1 minute; ③1 sweeping: without adding chemicals, stirring for 2 minutes; obtain copper middlings and copper roughing tailings;

[00...

Embodiment 2

[0029] Copper-sulfur ore with 0.64% Cu, 26.15% pyrrhotite and 8.45% pyrite.

[0030] 1) Raw ore is crushed and ground to a particle size of -0.074mm, accounting for 75%;

[0031] 2) Magnetic separation: the magnetic field strength is 0.5T to obtain pyrrhotite concentrate and pyrrhotite tailings;

[0032] 3) Gradient magnetic separation: Pyrhotite tailings undergo gradient magnetic separation with a magnetic field strength of 1.0T to obtain copper magnetic separation concentrate and copper magnetic separation tailings;

[0033] 4) Copper flotation: Copper flotation for copper magnetic separation tailings, ① 1 roughing: add 300 g / ton of quicklime, 8 g / ton of butyl xanthate, 3 g / ton of thiocarbamate to the copper magnetic separation tailings tons and 2 # Oil 1 g / ton, stirring for 4 minutes; ②1st selection: without adding chemicals, stirring for 1 minute; ③2 times of sweeping: without adding chemicals, stirring for 5 minutes; obtain copper middlings and copper roughing tailings;...

Embodiment 3

[0038] Copper-sulfur ore with 0.92% Cu, 25.12% pyrrhotite and 13.26% pyrite.

[0039] 1) Raw ore crushing and grinding until the particle size is -0.074mm accounts for 70%;

[0040] 2) Magnetic separation: the magnetic field strength is 0.45T to obtain pyrrhotite concentrate and pyrrhotite tailings;

[0041] 3) Gradient magnetic separation: Pyrrhotite tailings undergo gradient magnetic separation with a magnetic field strength of 0.70T to obtain copper magnetic separation concentrate and copper magnetic separation tailings;

[0042] 4) Copper flotation: Copper flotation for copper magnetic separation tailings, ① 1 roughing: add 520 g / ton of quicklime, 12 g / ton of butyl xanthate, 3 g / ton of thiocarbamate to the copper magnetic separation tailings tons and 2 # Oil 1 g / ton, stirring for 4 minutes; ②1 selection: without adding chemicals, stirring for 2 minutes; ③1 sweeping: without adding chemicals, stirring for 3 minutes; obtain copper middlings and copper roughing tailings;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com