Baking composite non-dairy cream and preparation method thereof

A non-dairy cream and baking technology, which is applied in the field of baked non-dairy cream and its preparation, can solve the problems of complicated ingredient management, many operation steps, and low work efficiency, and achieve the effects of saving baking time, uniform texture, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

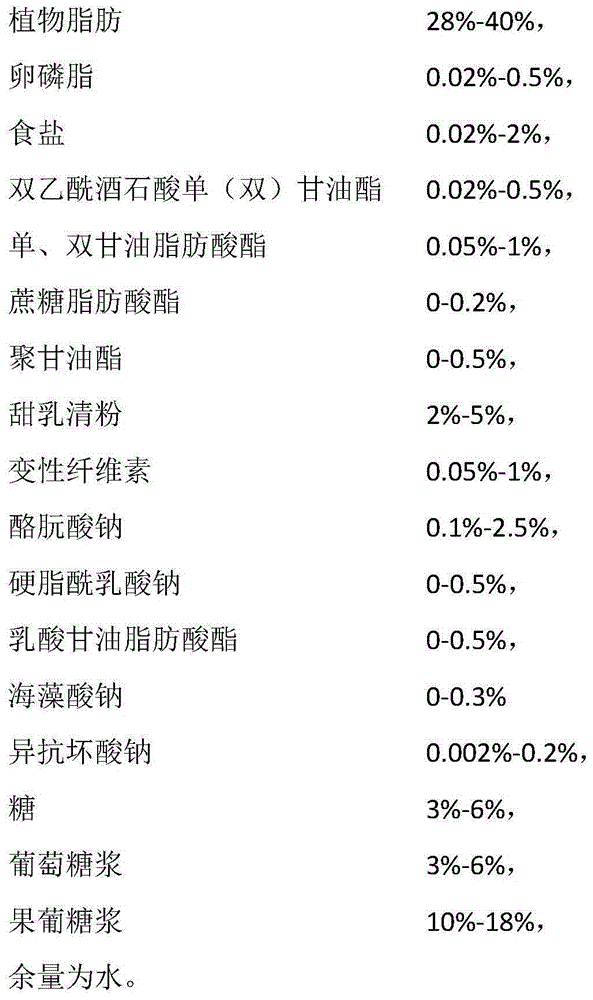

Method used

Image

Examples

Embodiment 1

[0026] Take 362 grams of hydrogenated palm kernel oil, 10 grams of salt, 0.2 grams of sodium erythorcorbate, 3 grams of diacetyl tartaric acid mono(diglyceride), 2.7 grams of sodium stearoyl lactylate, 2 grams of mono- and diglyceride fatty acid esters, sucrose 1.2 grams of fatty acid esters, 3 grams of lecithin, 1.0 grams of polyglycerol esters, 7.0 grams of denatured cellulose, 7.5 grams of sodium caseinate, 30 grams of sweet whey powder, 30 grams of sugar, 107 grams of fructose syrup, 45 grams of glucose syrup grams, 386.6 grams of water.

[0027] Process preparation:

[0028] Melt hydrogenated palm kernel oil and heat up to 60°C, add lecithin, diacetyl tartaric acid mono(diglyceride), sodium erythorcorbate, sodium stearoyl lactylate, mono- and diglyceride fatty acid ester, sucrose fatty acid ester, Polyglyceryl esters, sodium erythorbate, denatured cellulose, sodium caseinate, sweet whey powder and table salt. And stir to disperse evenly. An oil phase mixture is obtaine...

Embodiment 2

[0031] Take 375 grams of hydrogenated palm kernel oil, 15 grams of table salt, 1.7 grams of sodium erythorcorbate, 3 grams of diacetyl tartaric acid mono(diglyceride), 2.6 grams of sodium stearoyl lactylate, 2 grams of mono- and diglyceride fatty acid esters, seaweed 1.1 grams of sodium phosphate, 4 grams of lecithin, 1.3 grams of monoglyceride lactate, 9.3 grams of denatured cellulose, 2.5 grams of sodium caseinate, 30 grams of sweet whey powder, 35 grams of sugar, 112 grams of fructose syrup, 45 grams of glucose syrup grams, 360.2 grams of water.

[0032] Melt hydrogenated palm kernel oil and heat up to 65°C, add lecithin, lactic acid monoglyceride, sodium stearoyl lactylate, mono- and diglyceride fatty acid esters, diacetyl tartaric acid mono- and diglycerides, erythorbic acid, sodium stearoyl lactylate, seaweed sodium nitrate, sweet whey powder, denatured cellulose and sodium caseinate. And stir to disperse evenly. An oily mixture is obtained. In addition, dissolve suga...

Embodiment 3

[0035] Take soybean oil 3000g, lecithin 25g, salt 100g, diacetyl tartaric acid mono(dig)glyceride 25g, mono- and diglyceride fatty acid ester 50g, sucrose fatty acid ester 10g, polyglycerol ester 20g, sweet whey powder 300g, denature Cellulose 50g, sodium caseinate 100g, sodium stearoyl lactylate 30g, lactic acid glycerin fatty acid ester 30g, sodium alginate 20g, sodium erythorcorbate 10g, sugar 400g, glucose syrup 400g, fructose syrup 1500g; add appropriate amount of water .

[0036] Heat soybean oil to 65°C, add lecithin, diacetyl tartaric acid mono(diglyceride), mono- and diglyceride fatty acid ester, sucrose fatty acid ester, polyglycerol ester, denatured cellulose and sodium caseinate, erythorbic acid , sweet whey powder, salt, and stir to disperse evenly to obtain oil phase mixture A; dissolve sugar, glucose syrup and fructose syrup in water at 70°C to obtain water phase solution B; pour water phase solution B into oil phase Mixture A, stir evenly and heat sterilize at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com