Plant incubator system

An incubator and plant technology, applied in the field of solar concentrating, can solve the problems of wasting electric energy, light intensity, unfavorable plant growth, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

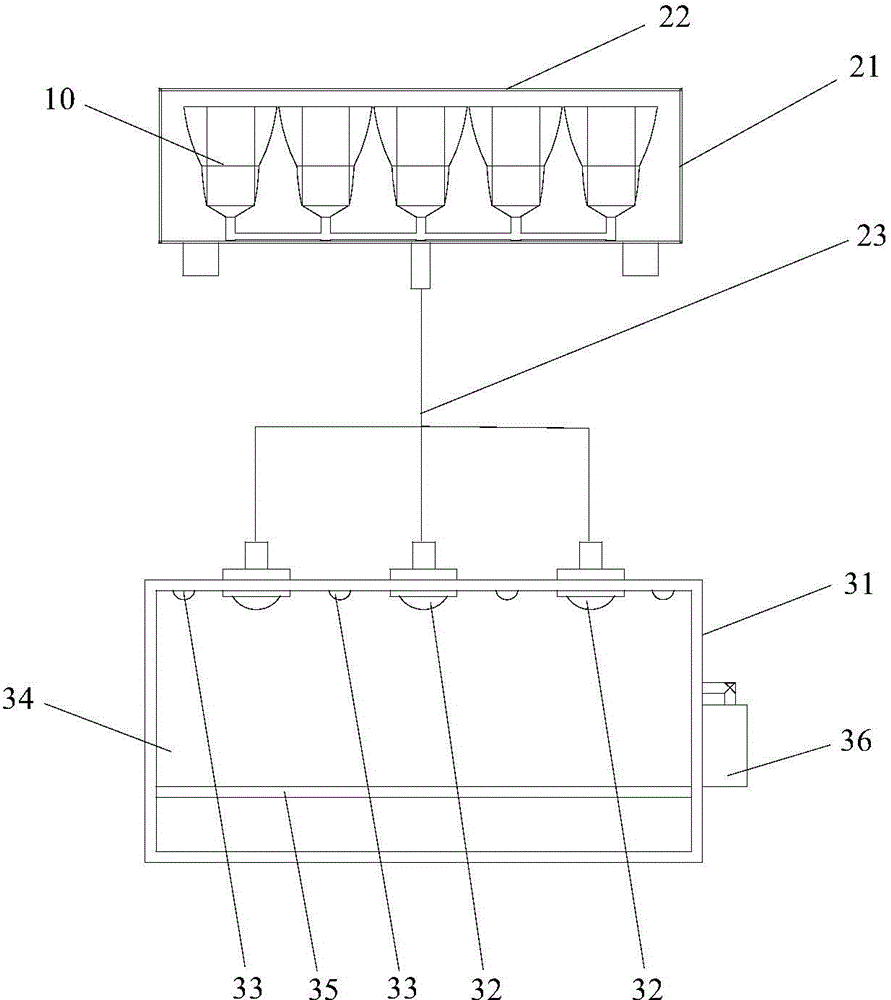

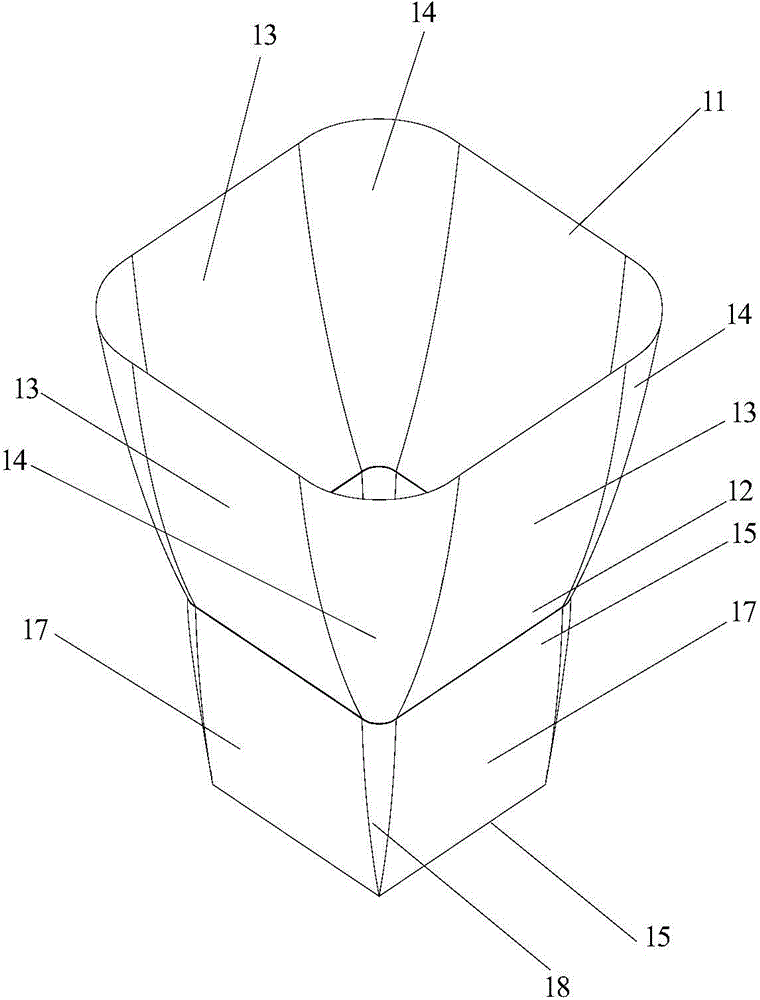

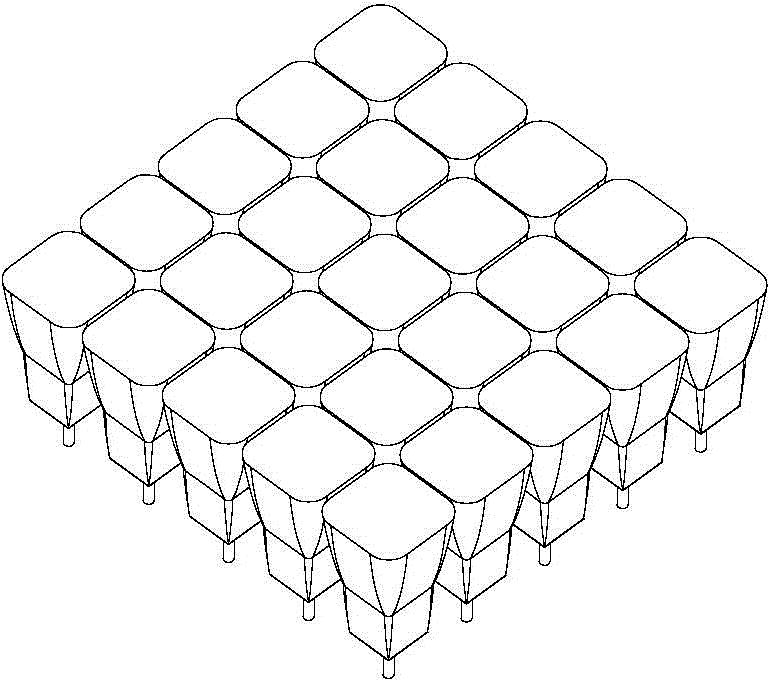

[0022] Such as Figure 1 to Figure 3 As shown, the plant cultivation box system of the present application, one embodiment thereof, includes a plant cultivation box and a light concentrating device. The concentrating device includes a concentrating array 10 and a transmission assembly. The concentrating array is connected to the plant cultivation box through the transmission assembly. The concentrating array includes a plurality of two-stage compound parabolic concentrators, and each concentrator is a reflective concentrator. , the light outlet of the first-stage concentrator is connected to the light-entrance of the second-stage concentrator, and each concentrator is generally in the shape of a quadrangular prism and includes a compound paraboloid on the side, that is, the concentrating array is a three-dimensional rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com