A double rotor motor

A motor and double-rotor technology, which is applied in the field of electric motors, can solve the problems of few uses, the advantages of double-rotor motors cannot be brought into play, and cannot be widely used, and achieve the effect of powerful functions, high usable value, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with the examples.

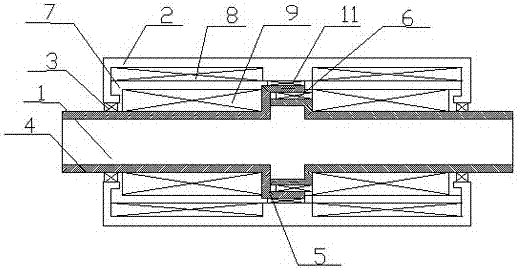

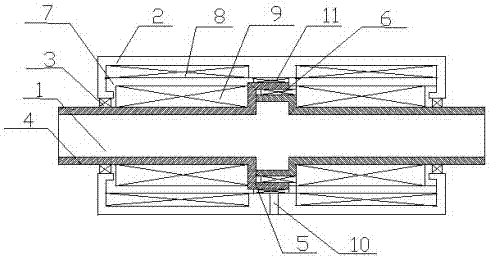

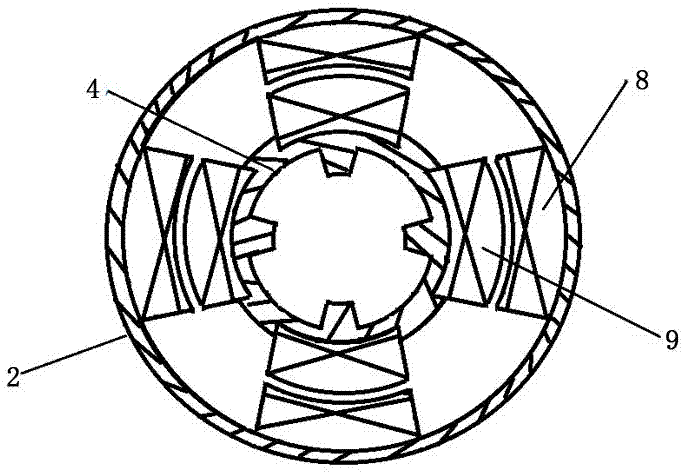

[0018] As shown in the figure, the double-rotor motor of the present invention includes a rotating shaft 1, a housing 2, a stator assembly 8 and a rotor assembly 9. The housing 2 is sleeved on the rotating shaft 1, and the two ends of the housing 2 are connected to each other through concentric bearings 3 and 9 respectively. The rotating shaft 1 is connected. The rotating shaft 1 is composed of two hollow half shafts 4 spliced together. The opposite ends of the two half shafts 4 are respectively provided with an annular shoulder 5 for stabilizing the half shaft 4. The inner wall of the hollow shaft 1 There are splines on the top, which can be nested with the corresponding linking tools. The hollow bearing I6 is nested between the two annular shaft shoulders 5, and the outer annular shaft shoulder 5 is connected to the housing 2 through the hollow bearing II11, and The casing 2 is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com