Multi-grade centrifugal pump guide vane hydraulic design method of high matching of inner and outer edge flow lines of blade

A technology for hydraulic design and centrifugal pumps, applied in calculation, special data processing applications, instruments, etc., can solve the problems that have not yet been reported publicly on the hydraulic design method of guide vanes of multi-stage centrifugal pumps, without considering the inner and outer edge flow of guide vanes Line matching problems, offset and other problems can be solved to save design time, improve design efficiency and reduce hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

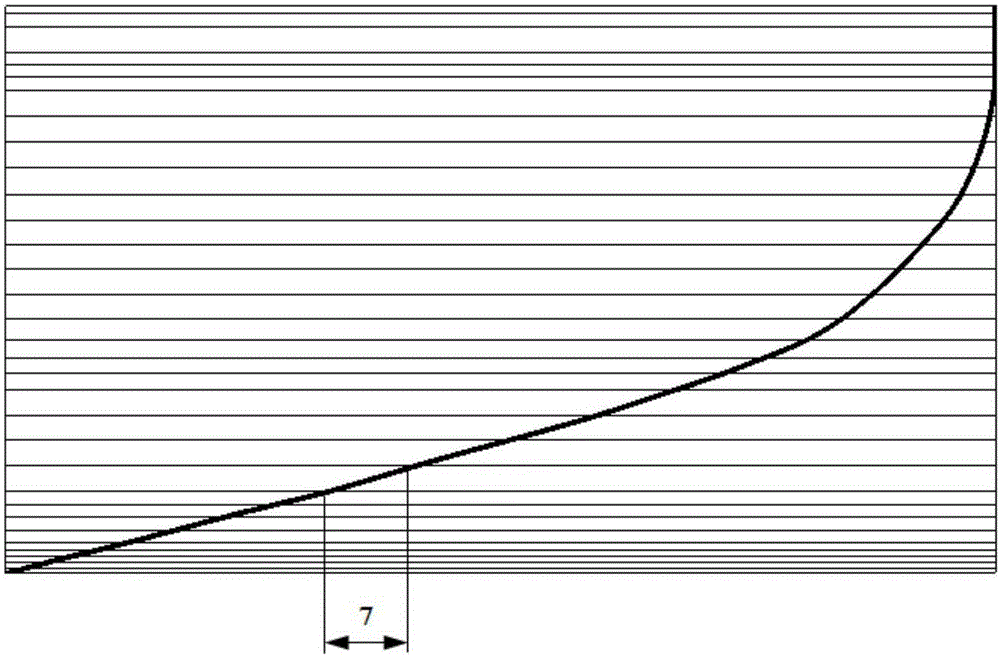

[0027] A three-stage centrifugal pump with a specific speed of 154, its design flow rate is Q=850m 3 / h, H=131m, n=1475r / min.

[0028] (1) Determine the main geometric parameters of the guide vane of the multistage centrifugal pump: inlet diameter D d1 , outlet diameter D d2 , the maximum outer diameter D dmax , Import and export placement angle, number of blades.

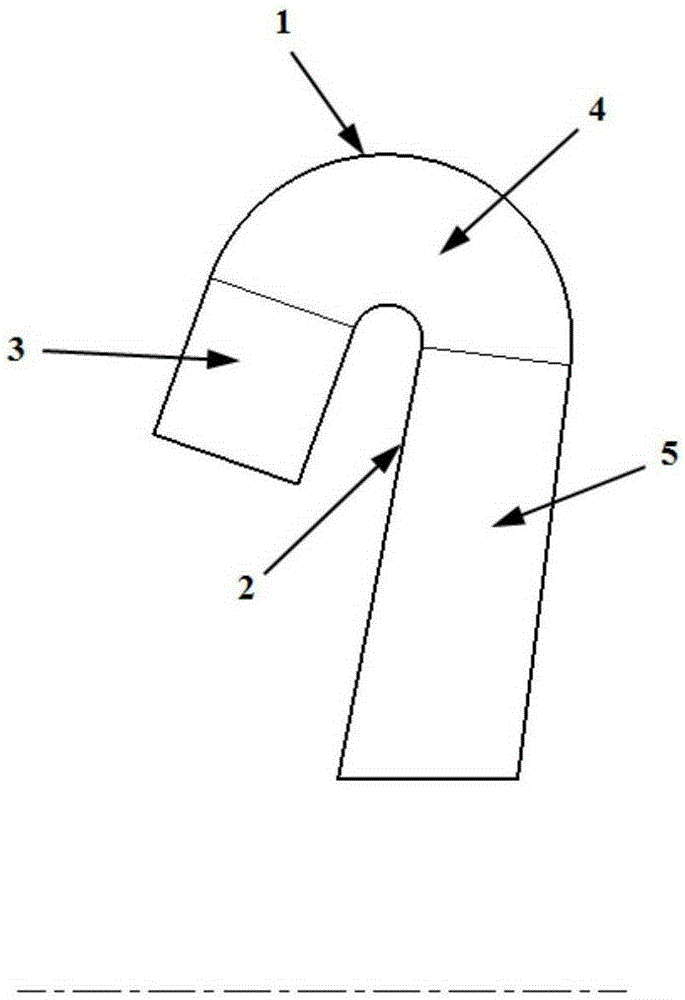

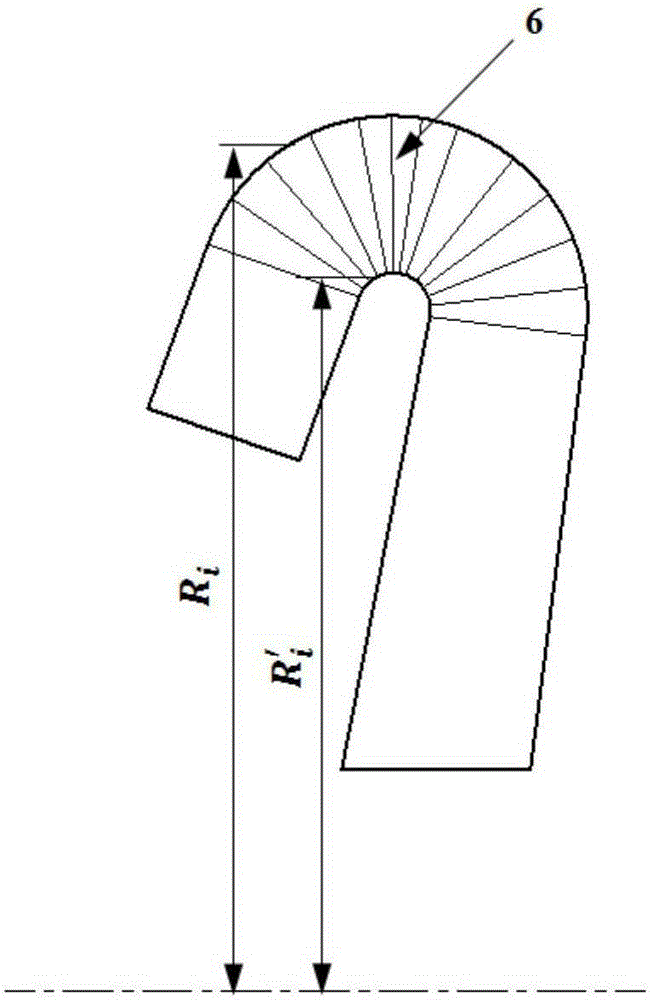

[0029] (2) The blade axial view of the guide vane of a multistage centrifugal pump is mainly composed of the outer edge streamline and the inner edge streamline, and the inner edge streamline and the outer edge streamline include three parts: the inlet section, the transition section, and the outlet section. Simplify the axial plane diagram of the guide vane, and design the inner and outer edge streamlines of the transition section as concentric circles, that is, the arcs at both ends share the origin, the inner and outer edge streamlines of the inlet section and the outlet section are parallel, and the outlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com