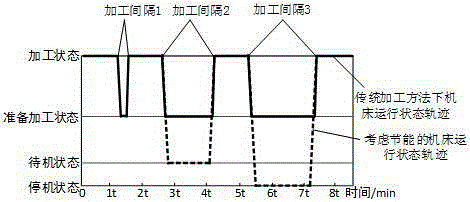

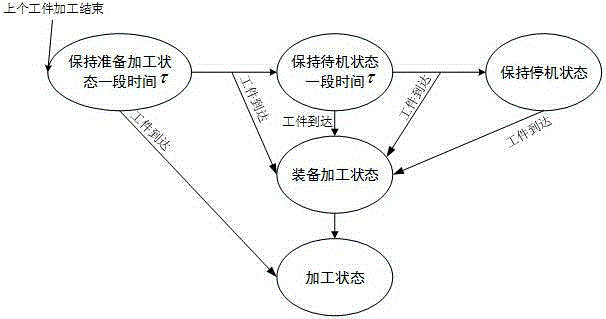

Machine tool energy-saving running method for switching machine tool states within random machining interval

A technology of operation method and processing state, applied in the direction of control/adjustment system, program control, instrument, etc., can solve the problems of immature research on energy saving of machine tools, etc., and achieve the effect of improving operability, good versatility, and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] Embodiment: On a CK6136H CNC lathe, the machine tool energy-saving operation method provided by the present invention is adopted. The part processed by the machine tool is a pallet, wherein the machine tool mainly completes drilling, rough / finish turning of the end face of the pallet and rough / finish turning holes during processing. The device for measuring machine tool power is HIOKI3390 power analyzer.

[0084] (1) Acquisition of basic parameters:

[0085] The basic parameters of the machine tool running state configured by the parameter configuration module are shown in Table 3 and Table 4. The time parameter of the processing interval is: the average processing interval of the machine tool is 24s; since the exponential distribution can be used to represent the time interval of independent random events, the index The reciprocal of the parameter λ in the distribution represents the expectation (average interval time) of the time interval of independent random events,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com