Gas-fired heating wall-mounted stove and operation control method thereof

A technology for gas heating and wall-mounted boilers, which is applied in lighting and heating equipment, fluid heaters, water heaters, etc., and can solve the problem of unfavorable wind pressure differential switch sensing air pressure, gas furnace failure to operate normally, and wind pressure differential switch failure rate advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

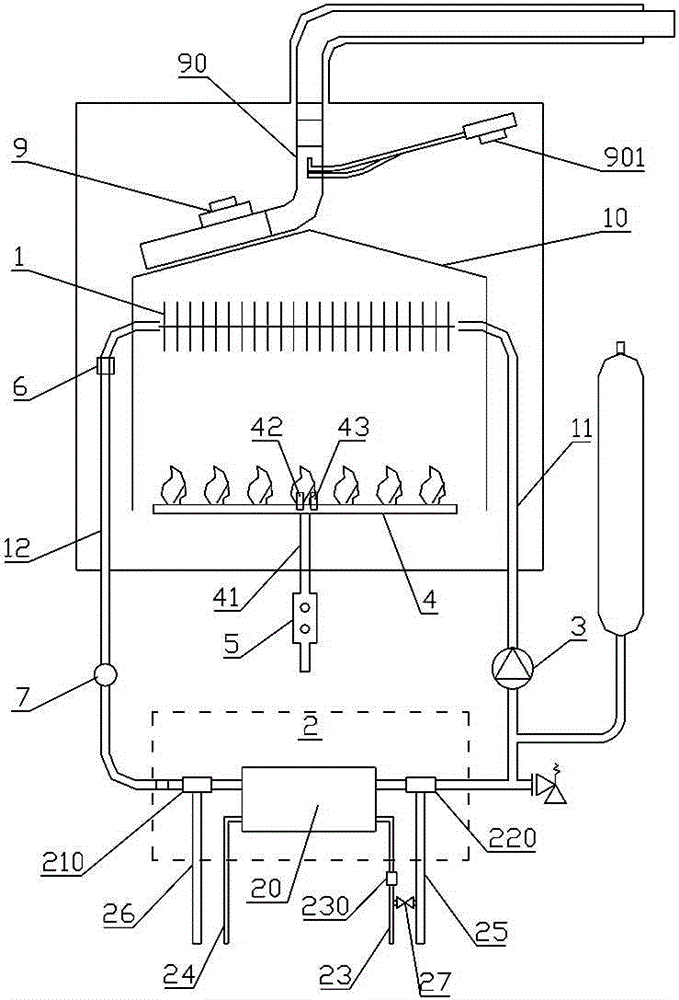

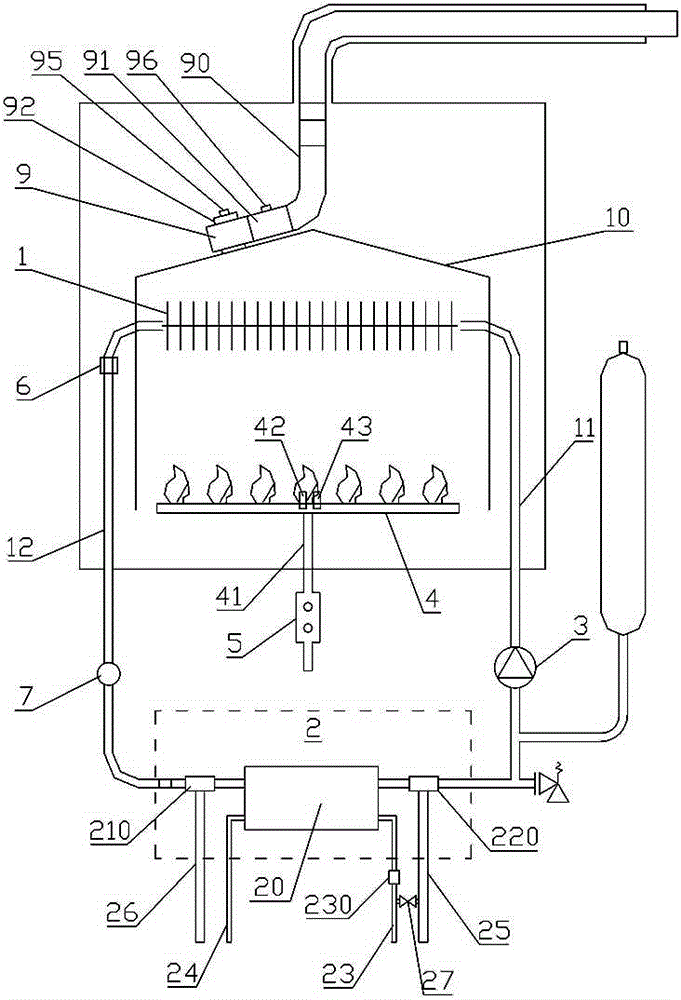

[0031] refer to Figure 2 to Figure 6 , a gas heating wall-hung boiler, which includes a main heat exchanger 1, a hot water heat exchange integration 2, a water pump 3, a burner 4, a gas valve 5 and a control circuit.

[0032]The main heat exchanger 1 and the burner 4 are installed in a combustion hood 10; the main heat exchanger 1 has a main water inlet pipe 11 and a main water outlet pipe 12, the water pump 3 is connected in series on the main water inlet pipe 11, and the main water outlet pipe 12 is provided There is an anti-dry thermostat 6 and a water pressure switch 7, and the hot water heat exchange integration 2 has a heat exchange water inlet, a heat exchange water outlet, a heating water inlet, a heating water outlet, a cold water inlet and a hot water outlet and are connected separately Main water outlet pipe 12, main water inlet pipe 11, heating water inlet pipe 25, heating water outlet pipe 26, cold water inlet pipe 23 and hot water outlet pipe 24. Hot water heat...

Embodiment 2

[0038] refer to figure 2 , Figure 5 and Figure 6 , the operation control method of the gas heating wall-hung boiler of embodiment 1, it comprises the following steps:

[0039] Step 1: Turn on the power supply of the gas-fired heating wall-hung boiler, open the water supply valve 27 to inject water into the heating system of the wall-hung boiler and the main heat exchanger 1, and after the water is filled, the water pressure reaches the preset pressure value so that the water pressure switch 7 is automatically closed, Start the gas heating wall-hung boiler, and the control center 8 controls the water pump 3 to start.

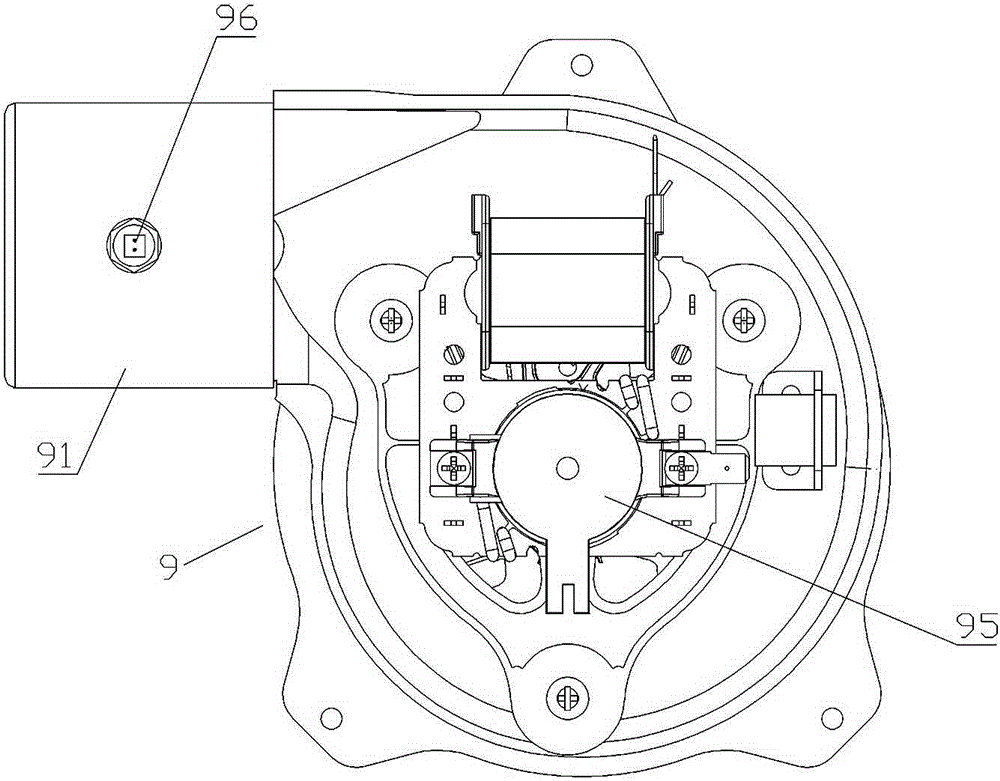

[0040] Step 2, after the water pump 3 runs for the set time, the fan 9 starts, the hall sensor 95 detects the speed of the fan motor 92, and when the fan motor 92 continues to run for the set time within the speed setting value, the control center 8 starts the ignition needle 42 discharge and ignite the burner 4, and the control center 8 opens the gas valve...

Embodiment 3

[0050] refer to Figure 7 , the difference between the gas heating wall-hung boiler of this embodiment and Embodiment 1 is that: the hot water heat exchange integration 2 includes a water outlet valve 21, a plate heat exchanger 20 and a water inlet joint 22, and the switching valve 210 is placed in the water outlet valve 21, and the water outlet There is a valve hot water channel in the valve 21, and the hot water outlet pipe 24 is connected to one end of the hot water receiving channel through the valve hot water channel; the three-way joint 220 is placed in the water inlet joint 22, and the water inlet joint 22 has a joint cold water channel , the cold water inlet pipe 23 is connected to the other end of the through-plate exchanging hot water channel through the joint cold water channel. The operation control method of the gas heating wall-hung boiler in this embodiment is the same as that in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com