Hybrid type dynamic pressure gas thrust bearing

A thrust bearing and hybrid technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to achieve high-speed operation, insufficient load capacity, and insufficient impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

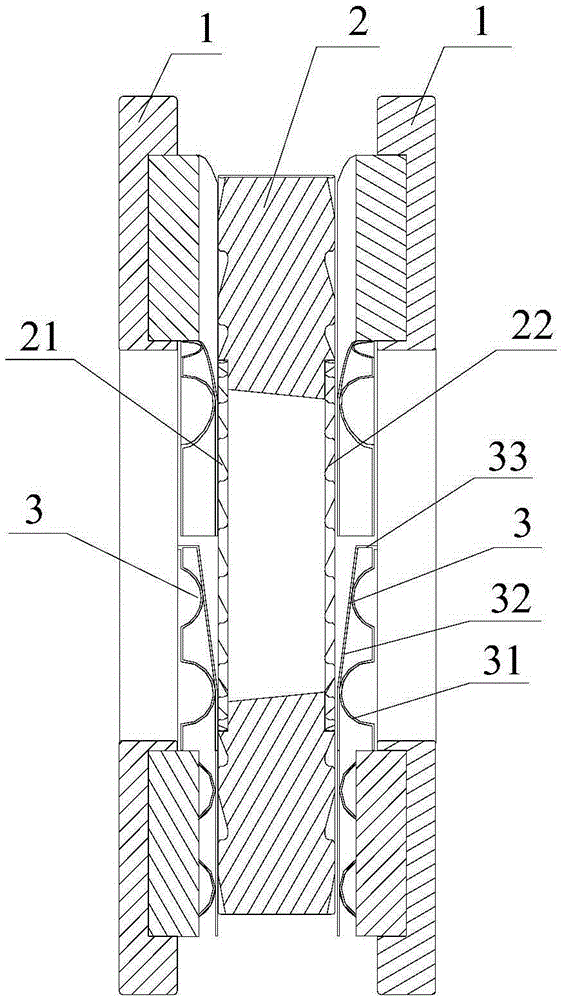

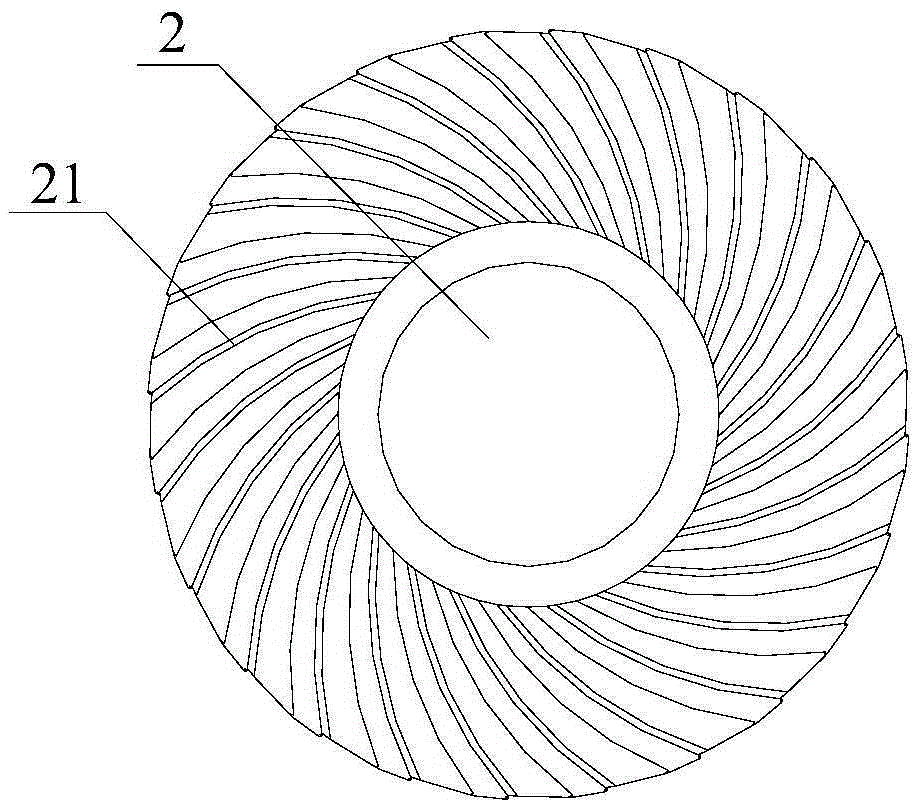

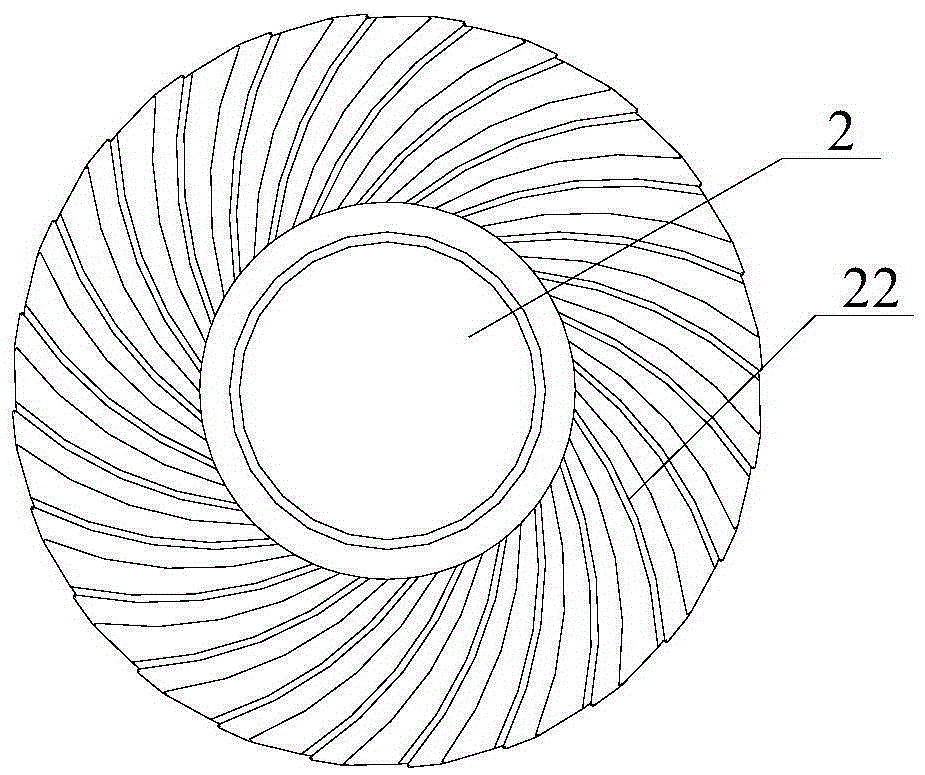

[0041] Such as figure 1 As shown: a hybrid dynamic pressure gas thrust bearing provided in this embodiment, including: two outer disks 1, an inner disk 2 is sandwiched between the two outer disks 1, and an inner disk 2 is arranged between each outer disk 1 and inner disk 2. There is a foil-shaped elastic member 3; the left end surface of the inner plate 2 is provided with a regular-shaped groove pattern 21, and the right end surface is provided with a regular-shaped groove pattern 22.

[0042] combine Figure 2a and Figure 2bIt can be seen that the groove pattern 21 on the left end surface of the inner disk 2 and the groove pattern 22 on the right end surface form a mirror image symmetry, the radial contour line of the groove pattern 21 on the left end surface and the diameter of the groove pattern 22 on the right end surface Form a one-to-one correspondence to the contour lines. The grooved patterns 21 and 22 have the same shape, and in this embodiment, both are in the sh...

Embodiment 2

[0046] combine Figure 6a , 6b , 7, 8 and 10, it can be seen that the difference between a hybrid dynamic pressure gas thrust bearing provided in this embodiment and embodiment 1 is only that:

[0047] The outer peripheral surface of the inner disc 2 is also provided with a grooved pattern 23, and the shape of the grooved pattern 23 on the outer peripheral surface is the same as that of the grooved patterns (21 and 22) on the left and right end faces (in this embodiment Both are in the shape of impellers), and the axial contour lines of the groove pattern 23 on the outer peripheral surface and the radial contour lines of the groove patterns (21 and 22) on the left and right end surfaces all form a one-to-one correspondence and intersect each other; namely:

[0048] The axial high line 231 in the groove pattern 23 on the outer circumferential surface corresponds to the radial high line 211 in the groove pattern 21 on the left end surface, and they meet each other before the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com