Variable-geometry RBCC (rocket based combined cycle) engine for ground experiment

A ground experiment and engine technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as dynamic sealing, and achieve the effect of simplifying variable geometry mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

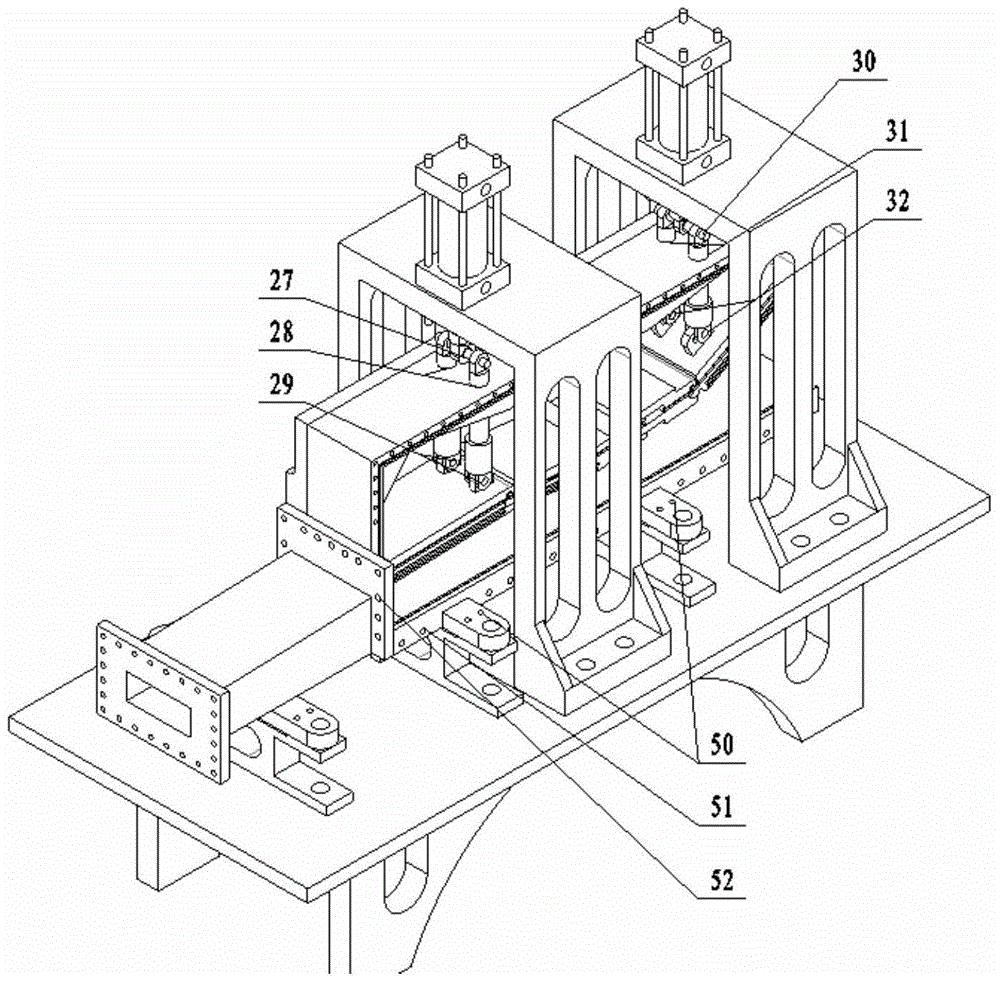

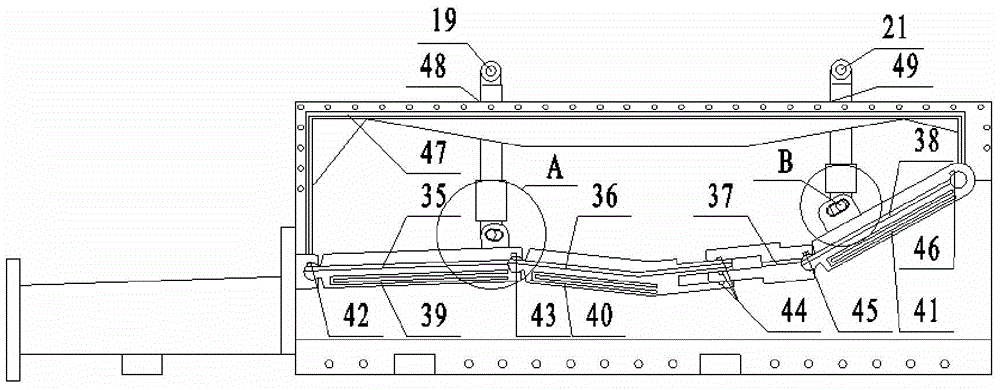

[0021] This embodiment is a variable geometry rocket-based combined cycle ground test engine.

[0022] refer to Figure 1 to Figure 6 , the variable geometry rocket-based combined cycle ground test engine consists of an engine 1, a test bench 2, and an engine actuator 3. The engine 1 is fixed on the experiment bench 2, and the two actuators are equidistant and vertically fixedly installed on the experiment bench 2. , the engine 1 is located in the two actuator brackets, and the test bench 11 is installed under the test bench 2. The engine consists of a fixed section combustion chamber 4, a variable section combustion chamber 52, a first upper cavity plate 5, a second upper cavity plate 6, a third upper cavity plate 7, a pin shaft 8, a pressure cavity cover plate 9, and a combustion chamber side Plate 10, combustion chamber bottom plate 51, connecting ear 50, first cylindrical hinge 23, second cylindrical hinge 24, third cylindrical hinge 25, U-shaped slide rail 26, lug 29, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com