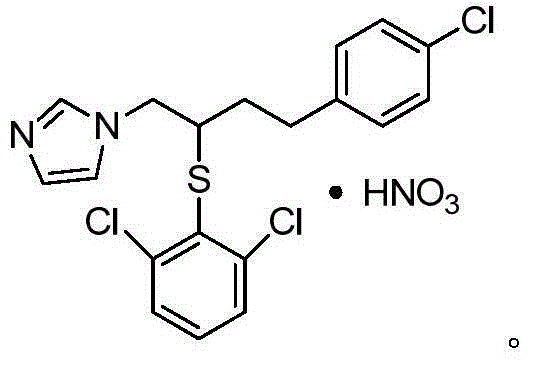

Method for industrially producing butoconazole nitrate

A technology of butconazole nitrate and imidazole, applied in the field of compound synthesis technology, can solve the problems of lack of impurities, complicated post-processing steps and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

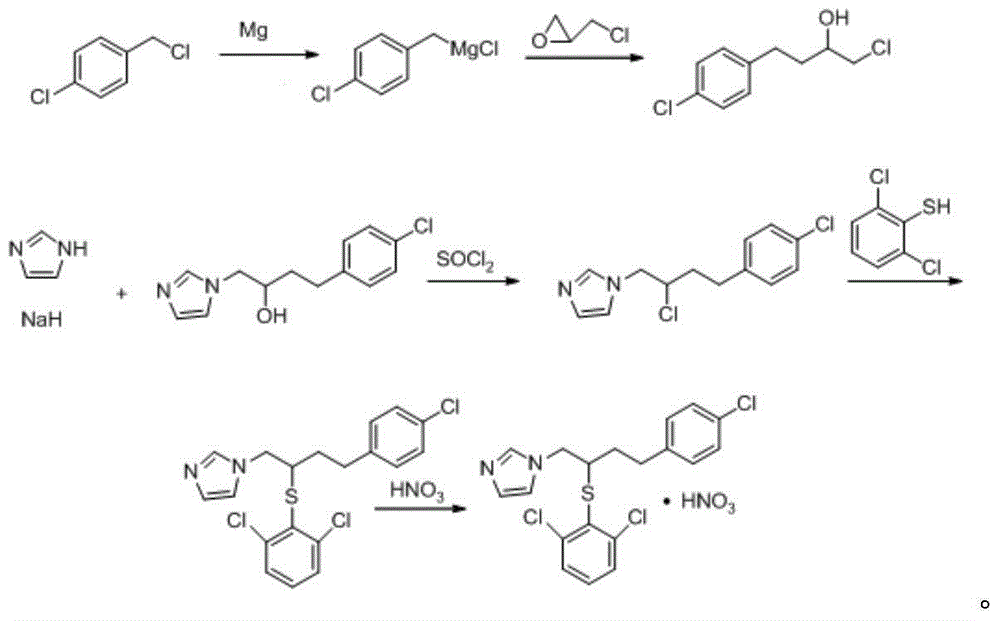

Method used

Image

Examples

Embodiment 1

[0066] Follow the steps below to produce butoconazole nitrate:

[0067] (1) Get 5kg1-(2-chloro-4-(4-chlorophenyl) butyl)-1 hydrogen-imidazole, 5kg2,6-dichlorothiophenol, 2.5kg anhydrous potassium carbonate and 40kg acetone, in Reflux reaction at 60°C for 5 hours, add 0.8kg of anhydrous potassium carbonate, reflux reaction at 60°C for 7 hours, slowly cool with circulating water at 0-4°C, centrifuge at 2825r / min for 20min, discard the solid, keep The liquid is the filtrate; the filtrate is concentrated at 60°C until no acetone is evaporated to obtain a concentrate;

[0068] (2) Take the concentrate obtained in step (1), add an extract composed of diethyl ether and water with a weight ratio of 2.5:1.5, after sufficient extraction, discard the aqueous phase, and leave the organic phase for subsequent use;

[0069] (3) Under ice-bath and stirring condition, in step (2) gained organic phase, dropwise add concentrated nitric acid, filter after stopping to generate precipitation; Dis...

Embodiment 2

[0072] Follow the steps below to produce butoconazole nitrate:

[0073] (1) Take 4kg1-(2-chloro-4-(4-chlorophenyl)butyl)-1hydro-imidazole, 4kg2,6-dichlorothiophenol, 1kg anhydrous potassium carbonate and 30kg acetone, 55℃ Under reflux for 4.5 hours, add 0.5kg of anhydrous potassium carbonate, reflux at 55°C for 6.5 hours, slowly cool with circulating water at 0-4°C, centrifuge at 2825r / min for 10min, discard the solid and keep the liquid , which is the filtrate; concentrate the filtrate at 55°C until no acetone is evaporated to obtain a concentrate;

[0074] Steps (2), (3) are the same as in Example 1.

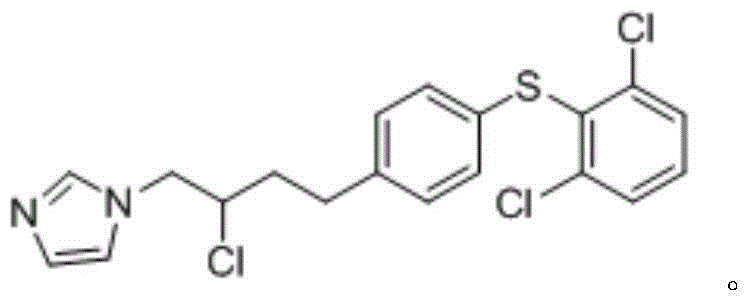

[0075] After testing, the yield of the product in this example was 89.58%. The target product and impurity content were detected by HPLC and standard substances. After testing, the content of the target product 1-(4-(4-chlorophenyl)-2-((2,6-dichlorophenyl)thio)butyl)-1 hydrogen-imidazole mononitrate was 91.44% , the content of the impurity 1-(2-chloro-4-(4-((2,6-dichloroph...

Embodiment 3

[0077] Follow the steps below to produce butoconazole nitrate:

[0078] (1) Take 6kg1-(2-chloro-4-(4-chlorophenyl)butyl)-1hydro-imidazole, 6kg2,6-dichlorothiophenol, 4kg anhydrous potassium carbonate and 50kg acetone, 65℃ Under reflux reaction for 5.5 hours, add 1kg of anhydrous potassium carbonate, reflux reaction at 65°C for 7.5 hours, slowly cool with circulating water at 0-4°C, centrifuge at 2825r / min for 30min, discard the solid, keep the liquid, It is the filtrate; the filtrate is concentrated at 65°C until no acetone is evaporated to obtain a concentrate;

[0079] Steps (2), (3) are the same as in Example 1.

[0080] After testing, the yield of the product in this example was 95.3%. The target product and impurity content were detected by HPLC and standard substances. After testing, the content of the target product 1-(4-(4-chlorophenyl)-2-((2,6-dichlorophenyl)thio)butyl)-1 hydrogen-imidazole mononitrate is 92.25% , the content of the impurity 1-(2-chloro-4-(4-((2,6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com