Preparation method of high-purity pitavastatin calcium

A kind of pitavastatin calcium, high-purity technology, applied in the field of medicine, can solve the problem that the lactone content is not easy to control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

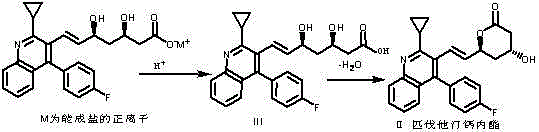

Problems solved by technology

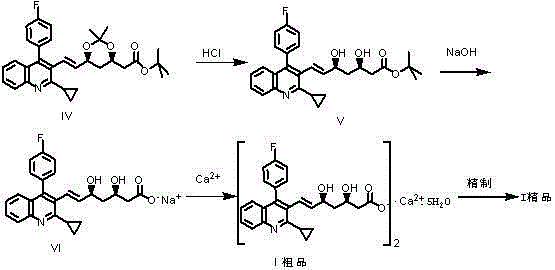

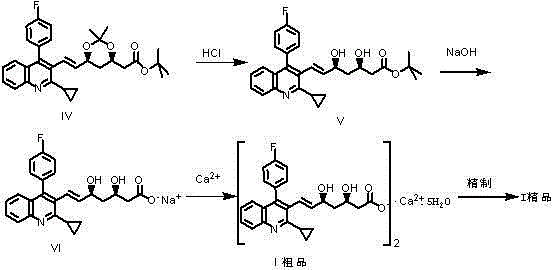

Method used

Image

Examples

Embodiment 1

[0030] Weigh 51.7g (0.1mol) of material IV, add 300ml ethanol, 50ml water and 15.2ml (0.15mol) of 36% hydrochloric acid, stir at room temperature for 5 hours, TLC detects that there is no raw material IV, then add 12g (0.3mol) sodium hydroxide The solution (dissolved with 100ml of water) continued to react for 6 hours, and no intermediate state V was detected by TLC. The reaction liquid ethanol was concentrated under reduced pressure, 100 ml of water was added, and extracted twice with dichloromethane. Take the water layer, adjust the pH to 10 with hydrochloric acid, and slowly add 6.6g (0.06mol) of calcium chloride aqueous solution (dissolved in 60ml of water) dropwise under nitrogen protection. After the dropwise addition is complete, continue stirring for 2 hours. Filter, water first, and dry below 45°C to obtain 83.5 g of crude pitavastatin calcium (with crystal water), with a yield of 86.0%. HPLC detection (area normalization method), purity 99.72%, lactone (II) 0.042%...

Embodiment 2

[0033] Weigh 51.7g (0.1mol) of material IV, add 300ml ethanol, 50ml water and 15.2ml (0.15mol) of 36% hydrochloric acid, stir at room temperature for 5 hours, TLC detects that there is no raw material IV, then add 12g (0.3mol) sodium hydroxide The solution (dissolved with 100ml of water) continued to react for 6 hours, and no intermediate state V was detected by TLC. The reaction liquid ethanol was concentrated under reduced pressure, 100 ml of water was added, and extracted twice with dichloromethane. Take the water layer, adjust the pH to 8 with hydrochloric acid, and slowly add 10.6g (0.06mol) of calcium acetate (monohydrate) aqueous solution (dissolved in 90ml of water) dropwise under nitrogen protection. After the dropwise addition is complete, continue stirring for 2 hours. Filter, water first, and dry below 45°C to obtain 86.0 g of crude pitavastatin calcium (with crystal water), with a yield of 88.6%. HPLC detection (area normalization method), purity 99.81%, lacton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com