Material conveying system, continuous material storing and discharging device and continuous material storing and discharging method

An unloading device and material storage technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of reduced ceramsite output, economic loss, and reduced ceramsite yield, and achieve continuous storage, unloading and transportation operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

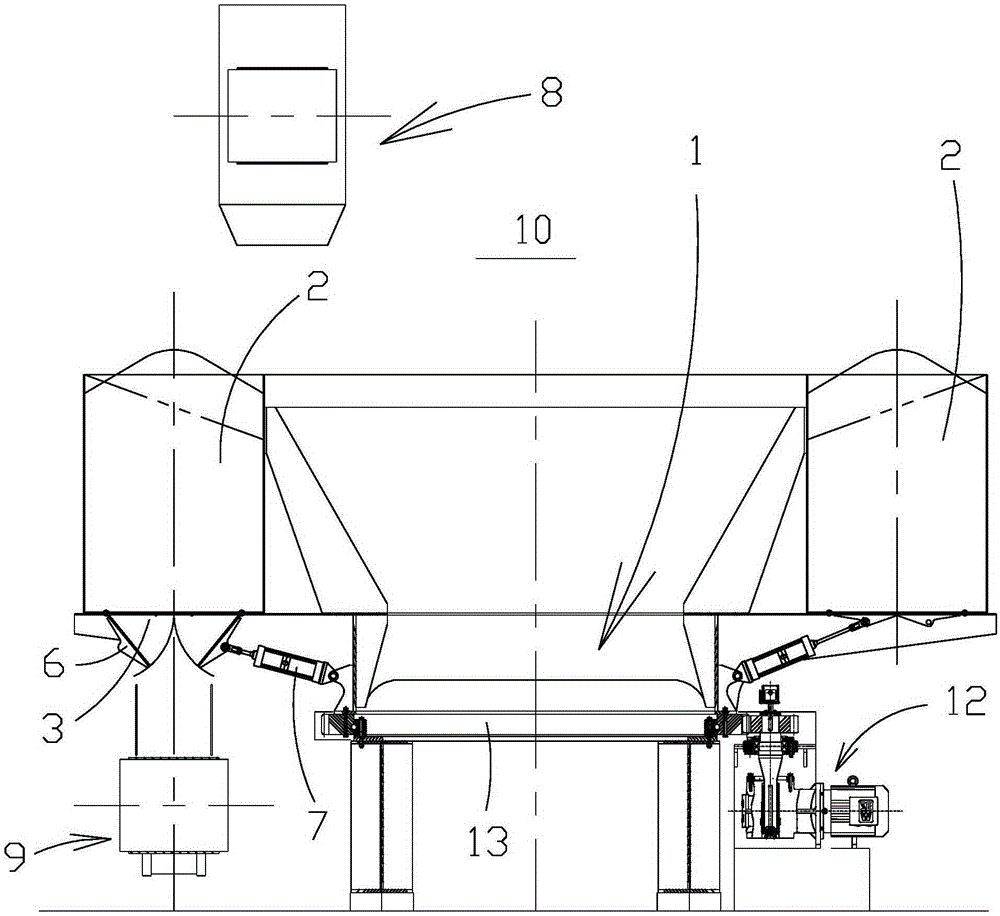

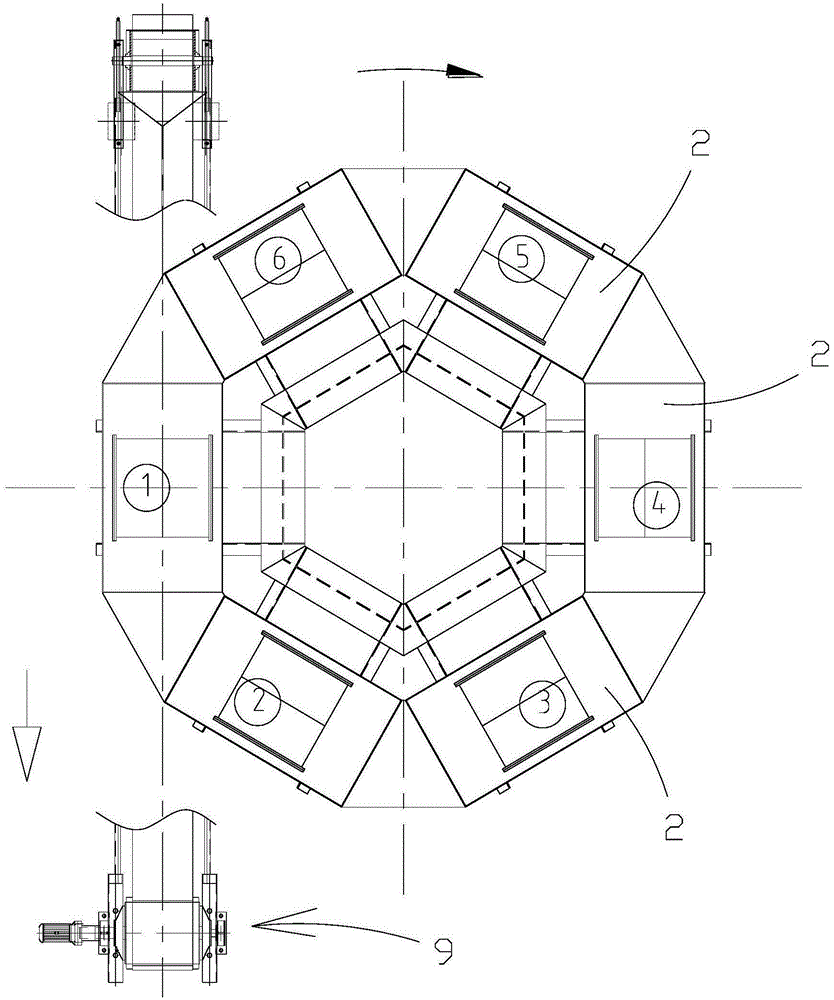

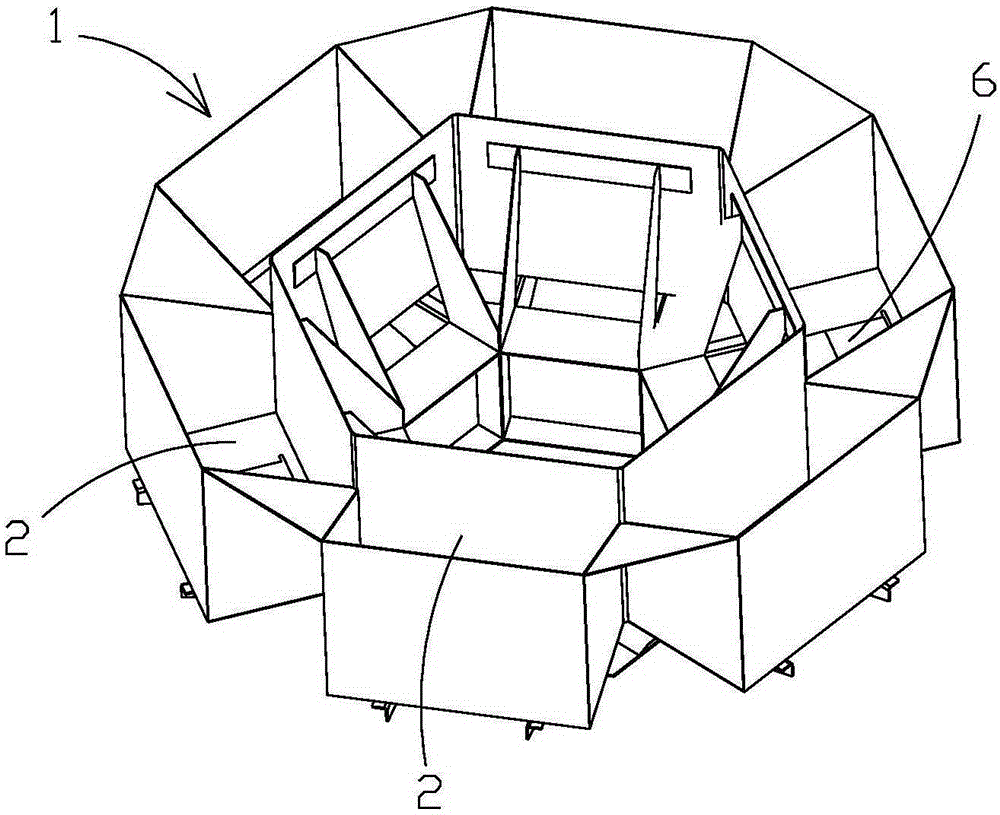

[0035] Such as figure 1 and 2 As shown, the continuous storage and unloading device 10 of the present invention includes a base frame and a supporting rotary body 1, wherein the supporting rotary body 1 is rotatably arranged on the base frame, for example, the supporting rotary body 1 can be manually rotated or through the following description The driving mechanism 12 is used to drive the rotation, and at the same time, a plurality of storage chambers 2 are arranged on the supporting rotary body 1 along the circumferential direction, for example figure 2Among the six storage chambers 2 shown in ①...⑥, and each storage chamber 2 is formed with a feed inlet an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com