Automatic tray circulating robot stacking system

An automatic circulation and palletizing system technology, which is applied in the direction of object stacking, object destacking, conveyor objects, etc., can solve problems such as robot palletizing systems that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

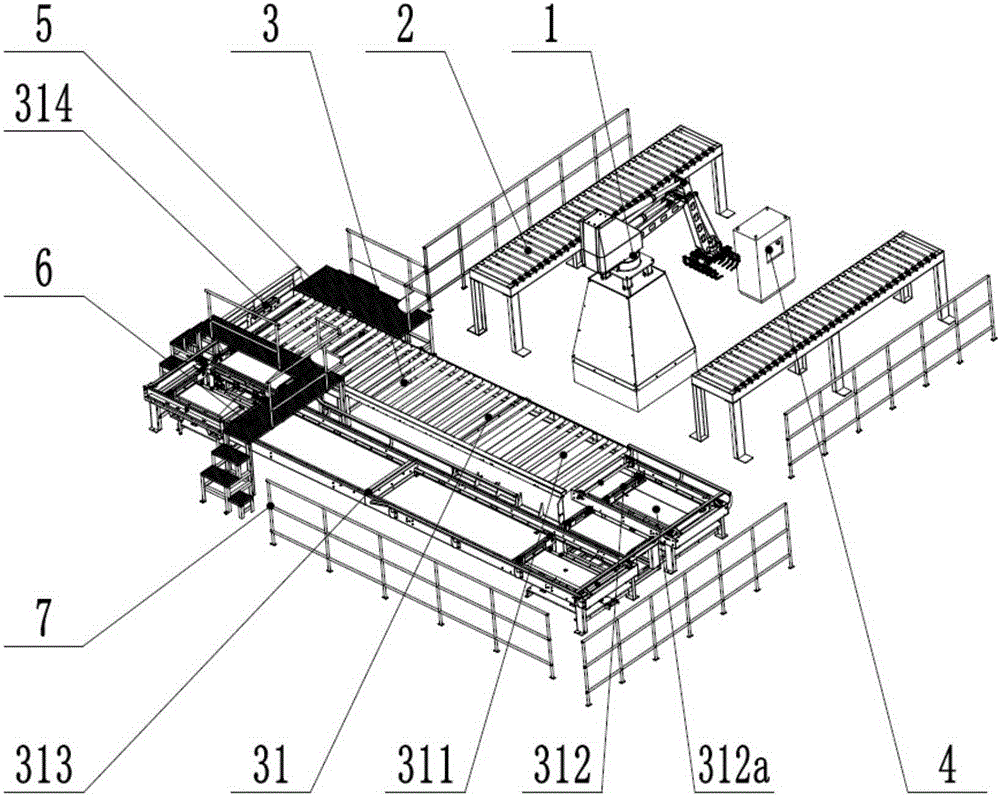

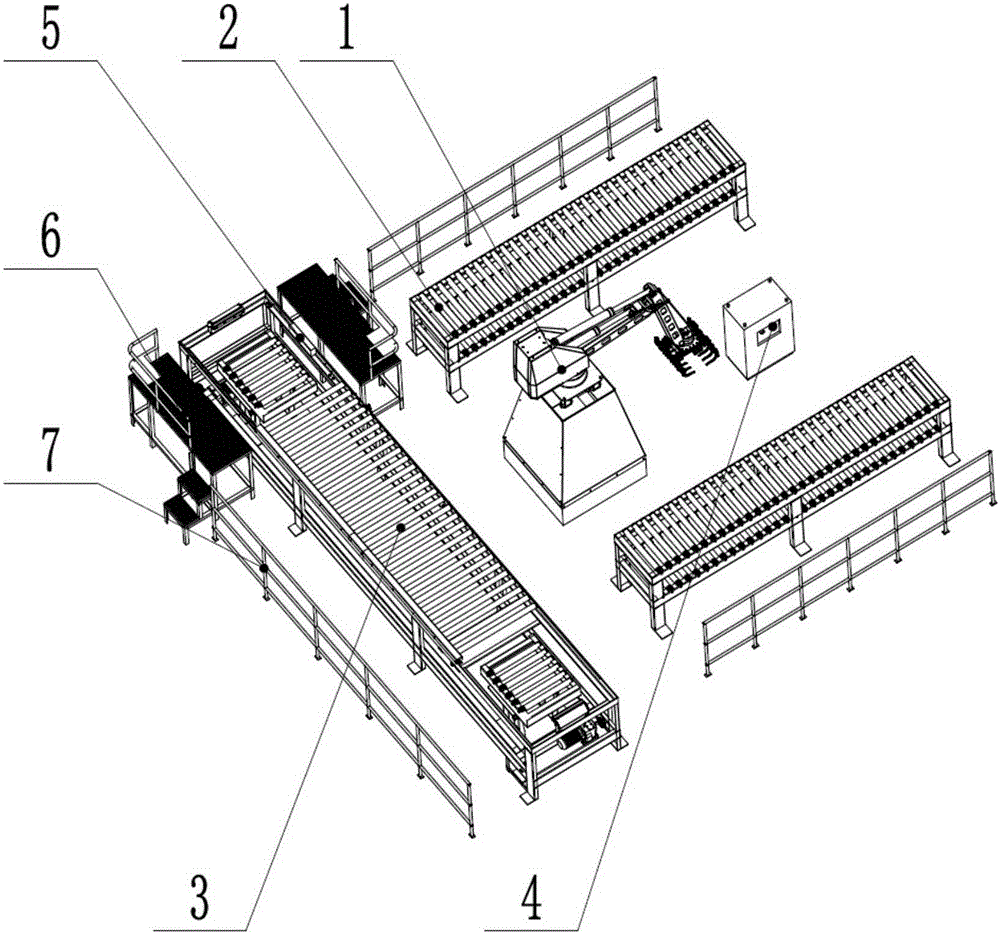

[0042] see figure 1 As shown, the automatic palletizing robot palletizing system of the first embodiment of the present invention is mainly composed of a palletizing robot 1 , a bag conveyor 2 , a pallet automatic circulating device 3 and a controller 4 . The bag conveyor 2, pallet automatic circulation device 3 and controller 4 are installed around the palletizing robot 1, and the palletizing robot 1, bag material conveyor 2 and pallet automatic circulation device 3 are electrically connected to the controller 4 for signal exchange. The controller 4 controls and detects the palletizing robot 1, the bag conveyor 2 and the pallet automatic circulation device 3 through connecting cables.

[0043] The automatic palletizing robot palletizing system for pallets of the present invention also includes sensors 5. There are multiple sensors 5, which are respectively installed on the frame of each conveyor of the automatic pallet circulating device 3, and are electrically connected with...

Embodiment 2

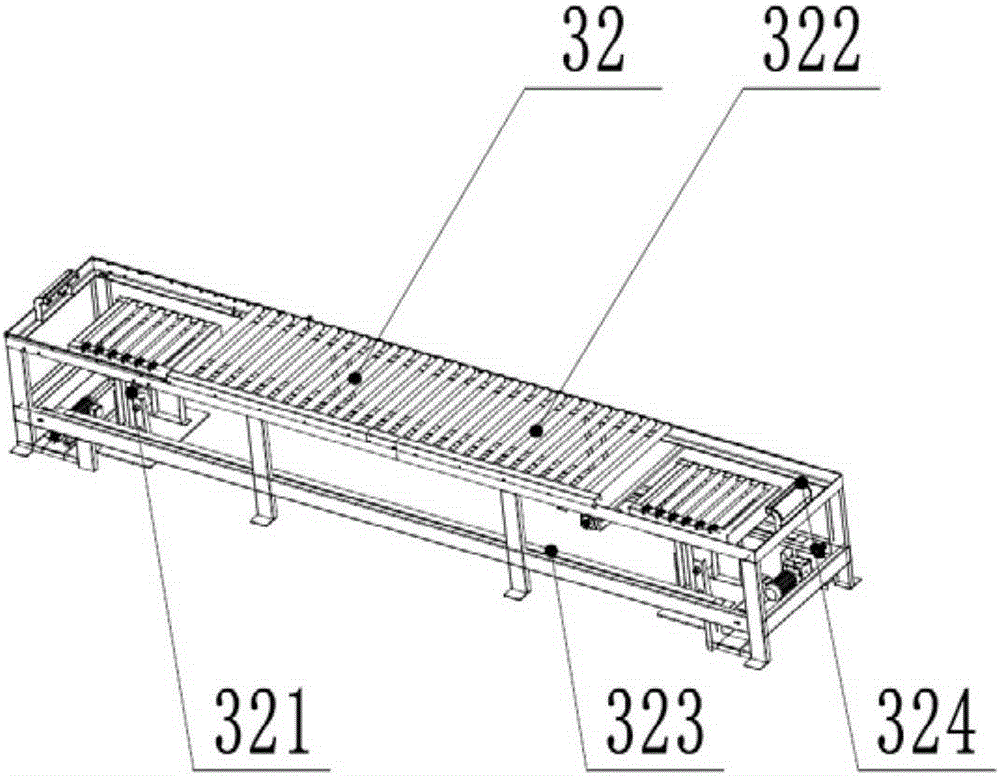

[0051] see figure 2 and image 3 As shown, the automatic palletizing robot palletizing system of the second embodiment of the present invention is similar to the first embodiment, the only difference is that the automatic pallet circulation device 3 is a linear downward circulation device 32 . The linear descending circulation device 32 is mainly composed of a lifting conveyor 321, a pallet conveyor 322 and a descending conveyor 323, wherein the descending conveyor 323 is installed below the pallet conveyor 322, and the lengths of the two are consistent, and the lifting conveyor 321 Installed inside the two ends of the pallet conveyor 322 and the down conveyor 323 , connecting the pallet conveyor 322 and the down conveyor 323 . Similarly, in order to prevent the pallet from slipping, locking blocks 324 are respectively installed at both ends of the frame of the pallet conveyor 322 .

[0052] The executive mechanism of the lifting conveyor 321 of the present invention is a c...

Embodiment 3

[0057] see Figure 4 and Figure 5 As shown, the automatic palletizing robot palletizing system of the third embodiment of the present invention is similar to the first and second embodiments, the only difference is that the automatic pallet circulation device 3 is a linear two-way circulation device 33 . The linear two-way circulation device 33 is mainly composed of an intermediate pallet conveyor 331, a left pallet conveyor 332 and a right pallet conveyor 333, wherein the left pallet conveyor 332 and the right pallet conveyor 333 are respectively installed on Both ends of the middle pallet conveyor 331 are connected in a straight line with the middle pallet conveyor 331, and the conveying working surfaces of the middle pallet conveyor 331, the left pallet conveyor 332 and the right pallet conveyor 333 are on the same horizontal plane . Similarly, in order to prevent the pallets from slipping, locking blocks 334 are respectively installed on the racks of the left pallet con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com