Knife rest of pencil sharpener

The technology of a pencil sharpener and a knife holder, which is applied in the field of stationery, can solve the problems of low reliability, poor cutting quality, complicated operation, etc., and achieve the effects of improving writing life, good cutting quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

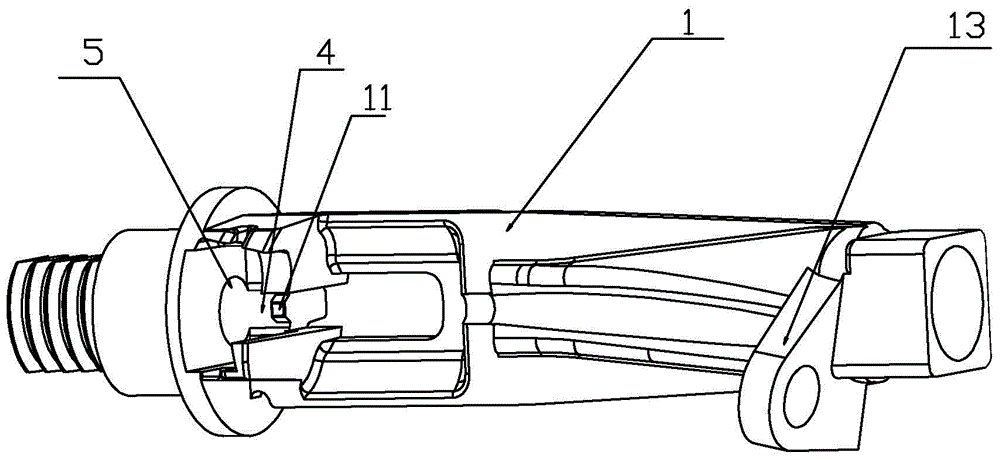

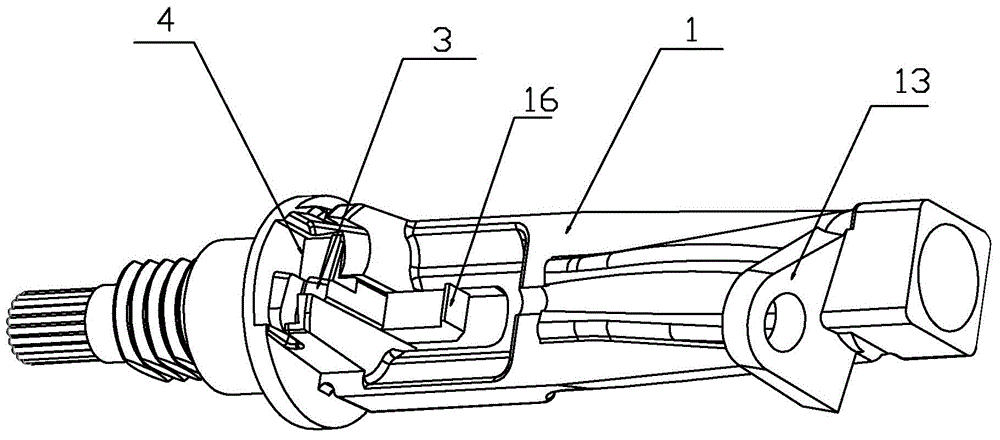

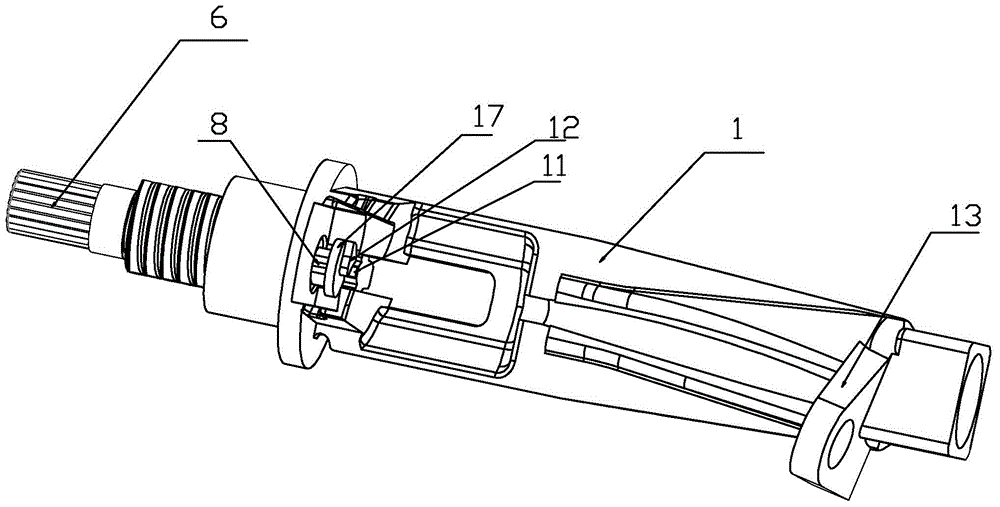

[0024] As shown in the figure, the present invention provides a knife holder for a pencil sharpener, which includes a knife holder 1 and a hob cutter shaft 2 on which a hob 14 is installed. One end of the knife holder 1 is provided with a knife shaft support seat 3. The other end of the tool rest 1 is provided with a cutter shaft support 13, and the two ends of the hob cutter shaft 2 are respectively installed on the cutter shaft support seat 3 and the cutter shaft support 13, and the described tool rest 1 is provided with a The angle adjustment device for the angle of the hob cutter shaft 2, the advantage of the present invention is to adjust the angle of the hob cutter shaft 2, and also adjust the cutting angle of the hob, which can meet the needs of different lengths of soft and hard pens as well as sharp and blunt , while simple in structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com