Sealing strip production device

A technology for production equipment and sealing strips, which is applied in metal processing and other directions, can solve the problems of non-uniform trimming length of sealing strips, inability to meet the punching position, and inability to incorporate edge trimming machines, etc., to achieve compact structure and high pass rate of finished products , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

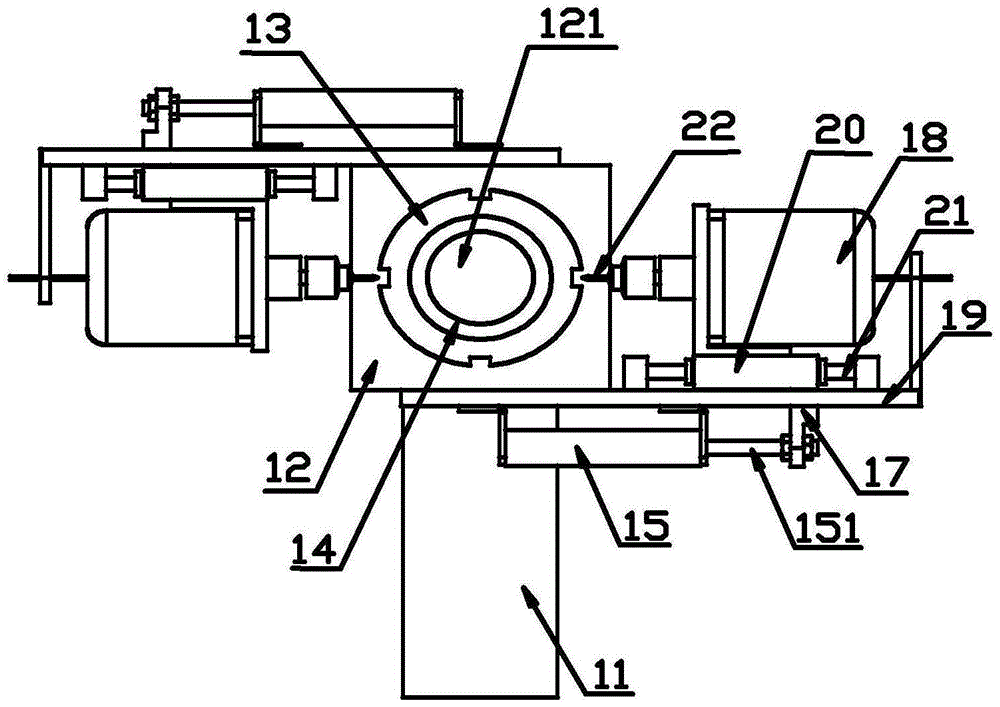

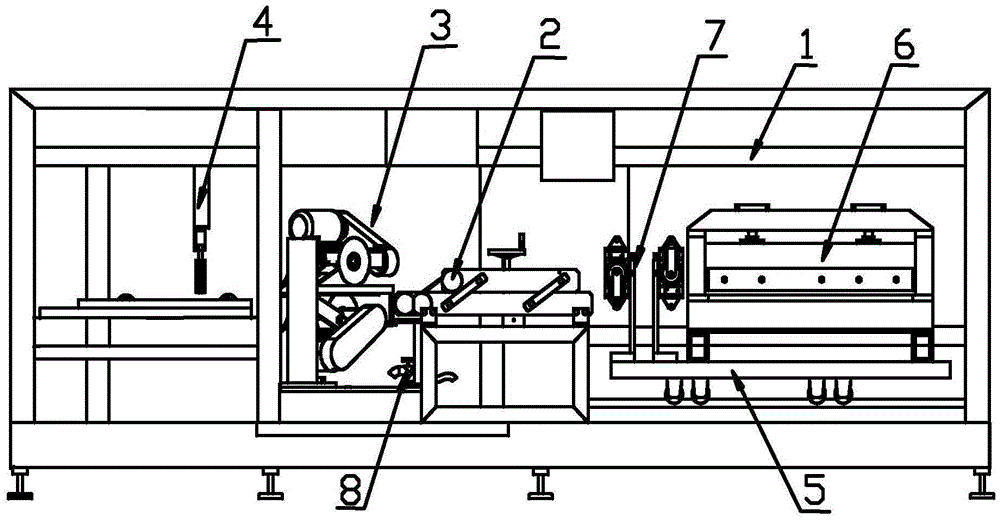

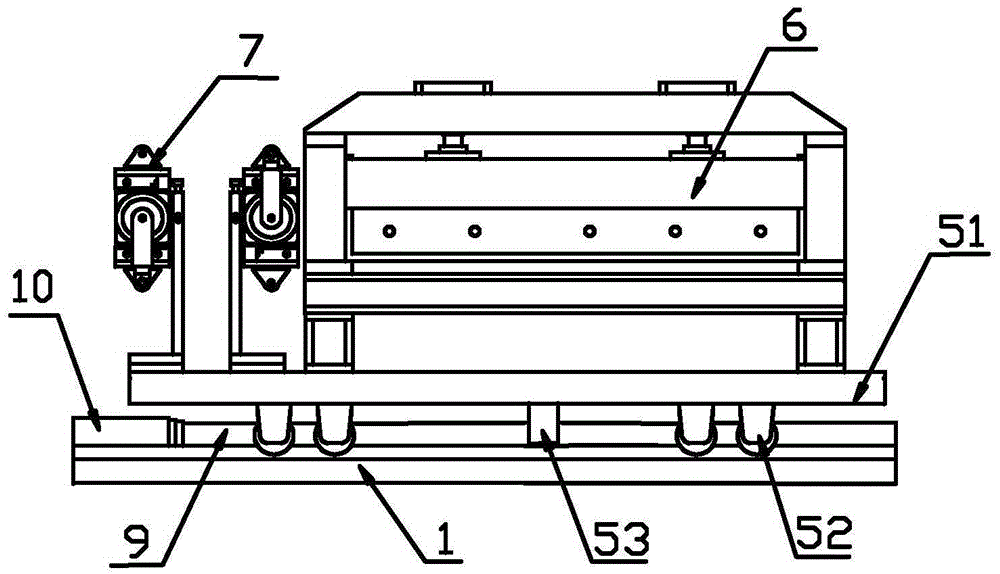

[0034] Such as Figure 1-2 As shown, a sealing strip production device includes a mounting frame 1, a traction mechanism 2, a corner cutting mechanism 3 and a clamping mechanism 4 are arranged in sequence on the mounting frame 1, and at least one punching mechanism is arranged side by side on the mounting frame 1. The hole mechanism 7 can increase or decrease the quantity of the hole punch mechanism 7 according to the requirement of the sealing strip for the number of holes to be punched, and the flexibility is high.

[0035] The moving mechanism 5 is provided with a trimming mechanism 6, and the bottom of the trimming mechanism 6 is connected with the mobile platform 51, which can realize trimming, punching, and corner trimming of the sealing strip at one time, improve productivity, and have a compact structure. The degree of automation is high, and in addition, according to actual production needs, the punching mechanism 7 or the trimming mechanism 6 can be removed.

[0036...

Embodiment 2

[0041] Such as figure 1 , 5 , 6 and 7, the clamping mechanism 4 includes a driving portion and a clamping portion, the driving portion includes a drive motor two 23 and a synchronous belt 24, the clamping portion is located on the synchronous belt 24, and the drive motor two 23 Control the reciprocating movement of the clamping part, and the moving speed of the clamping part is consistent with the transmission speed of the sealing strip, which can effectively avoid the phenomena of pulling and folding of the sealing strip.

[0042] Described clamping part comprises fixed plate two 25 and clamping part 26, and described fixed plate two 25 is provided with clamping cylinder 27 and connecting plate 28, and described connecting plate 28 is connected with fixed plate two 25 movably, and described The connecting plate 28 is arranged as an L-shaped structure, and its number is two pieces, and the two connecting plates 28 are arranged oppositely. One end of the connecting plate 28 is...

Embodiment 3

[0047] Such as Figure 1-9 As shown, the specific working process of a sealing strip production device is as follows:

[0048] (1) Adjust the relative position of the moving mechanism 5 on the mounting frame 1 according to the requirement of the trimming length of the sealing strip;

[0049] (2) The sealing strip passes through the edge trimming mechanism 6, the punching mechanism 7, the traction mechanism 2, the corner cutting mechanism 3 in sequence, and reaches the clamping mechanism 4;

[0050] (3) The clamping part 26 clamps the sealing strip, and under the action of the driving motor 23, the clamping part 26 moves to the storage place for the sealing strip, and places the clamped sealing strip in the storage place;

[0051] (4) Under the action of the driving motor 23, the clamping part 26 is reset, and the operations of clamping and placing the sealing strip are repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com