Pipe penetrating machine

A technology of a pipe threading machine and a frame, which is applied in the field of pipe threading machines and can solve the problems of difficult manual operation, high production cost, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

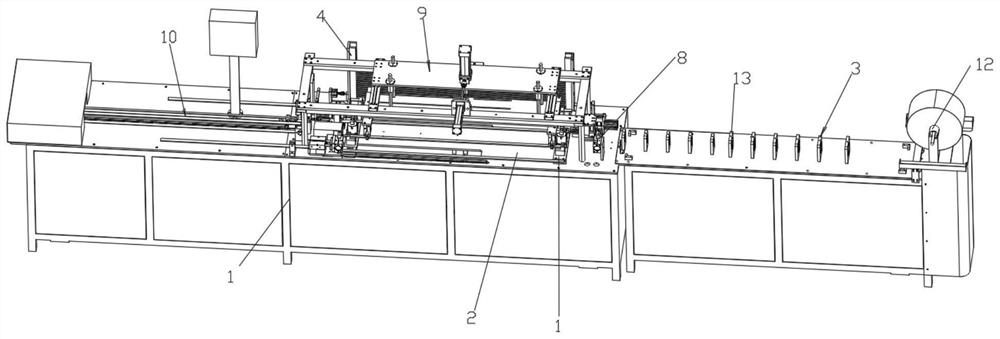

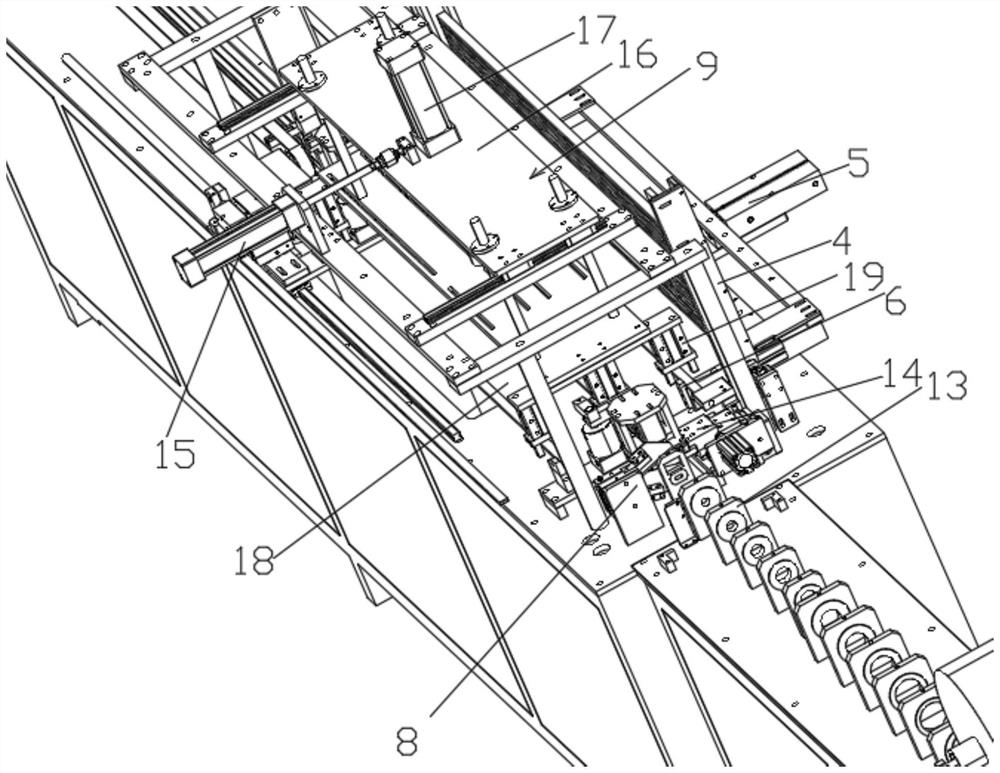

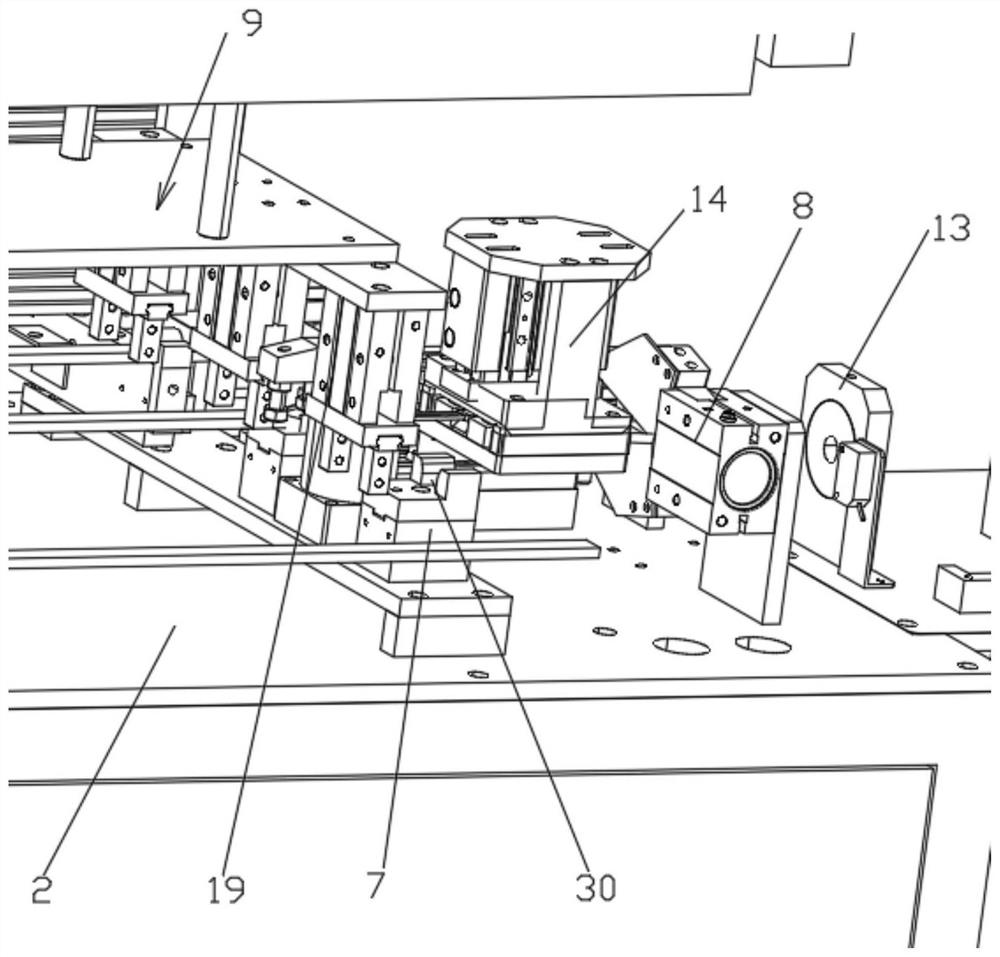

[0022] Example: as Figure 1-5 As shown, the pipe threading machine of the present invention includes a frame 1 on which an assembly table 2 is arranged, and an insulating paper forming mechanism 3 is arranged at the front end of the assembly table 2. One side is provided with a silo 4 for stacking a plurality of aluminum tubes of a certain length, and the bottom of the silo 4 is provided with a pushing cylinder 5 for pushing the bottommost aluminum tube to the assembly table. A limit plate 6 on the assembly table 2 that cooperates with the pusher cylinder 5, a limit cavity for limiting the position of the aluminum tube is formed between the limit plate 6 and the pusher cylinder 5, and the composition table 2 is provided with A plurality of equidistant positioning blocks 7 for positioning both ends of the aluminum tube, each positioning block 7 is provided with a positioning groove 30 for positioning the aluminum tube, one of the positioning blocks 7 is butted with the paper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com