Integrated reversing joint device applied to robots

A robot and joint technology, applied in the field of integrated reversing joint devices, can solve the problems of inconvenient control of the mechanical arm, high assembly cost and design cost, and achieve the effect of improving the appearance, simple structure and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

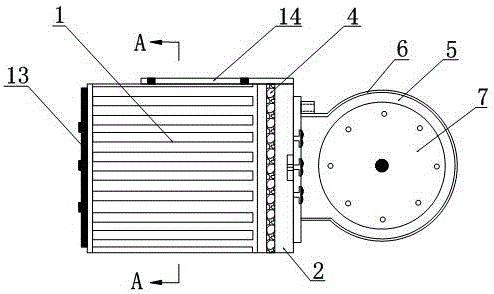

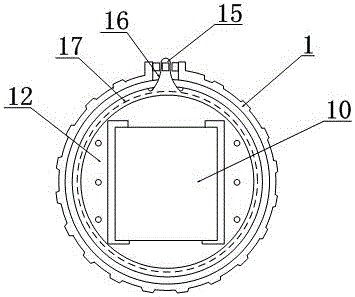

[0031] Such as Figure 1~5 As shown, the present invention provides a new robot joint reversing control device, which includes a housing 1, a bearing 2, an external joint 5, a brush base module, a crank load tray 7, a first gear motor 10 and a driving device.

[0032] The first reduction motor 10 is connected with the crank load tray 7 through the transmission shaft 8, and is used for controlling the rotation of the crank load tray 7 in the X direction. The outer joint 5 is located outside the casing 1, and the outer joint has gears for transmitting reversing power inside, and a protective cover 6 is also arranged outside the outer joint. At the same time, the outer joint 5 is provided with a drive shaft hole in the Y direction, and the drive shaft 8 passes through the drive shaft hole, and then connects to the crank load tray 7 .

[0033] The driving device is used to control the outer joint and the crank load tray 7 to rotate in the Y direction at the same time. Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com