Saw web capable of preventing edge breakage during cutting

A saw blade and sawtooth technology, which is applied to the field of high-speed cutting circular saw blades, can solve problems such as edge chipping, and achieve the effects of preventing cutting edge chipping, ensuring strength, and smooth and beautiful edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

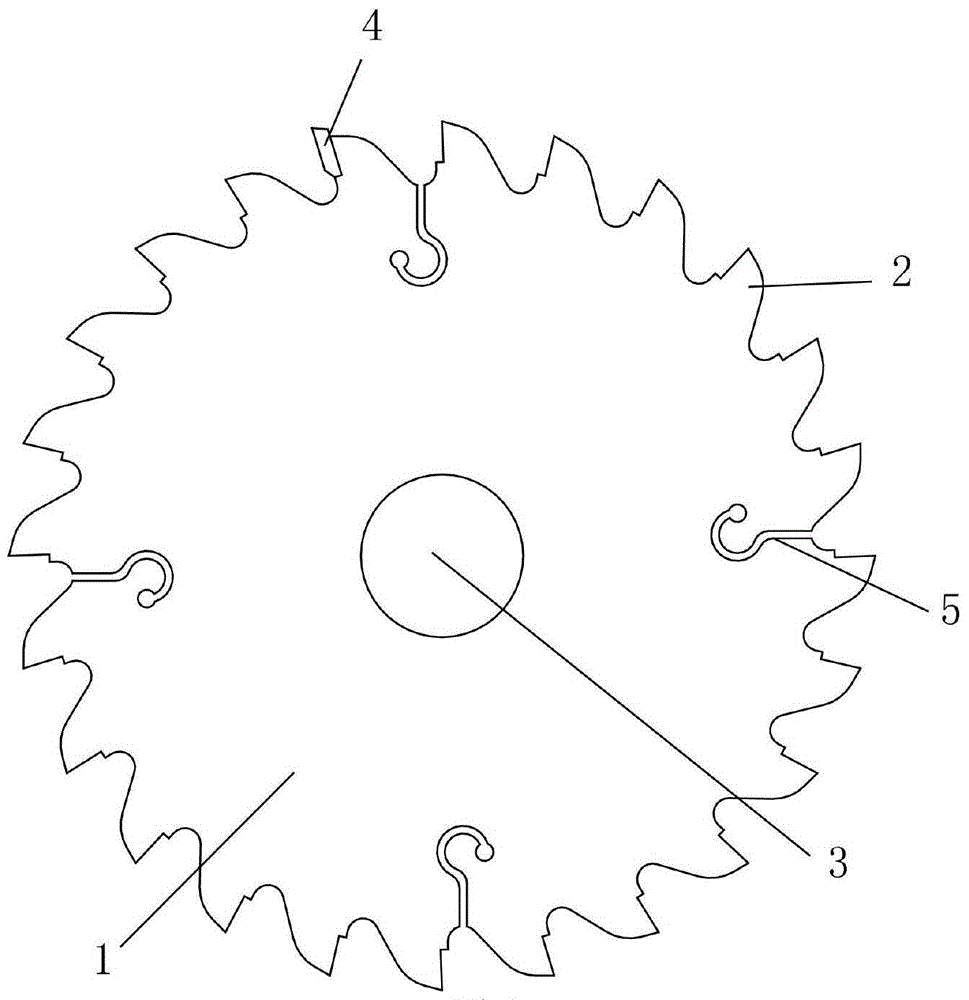

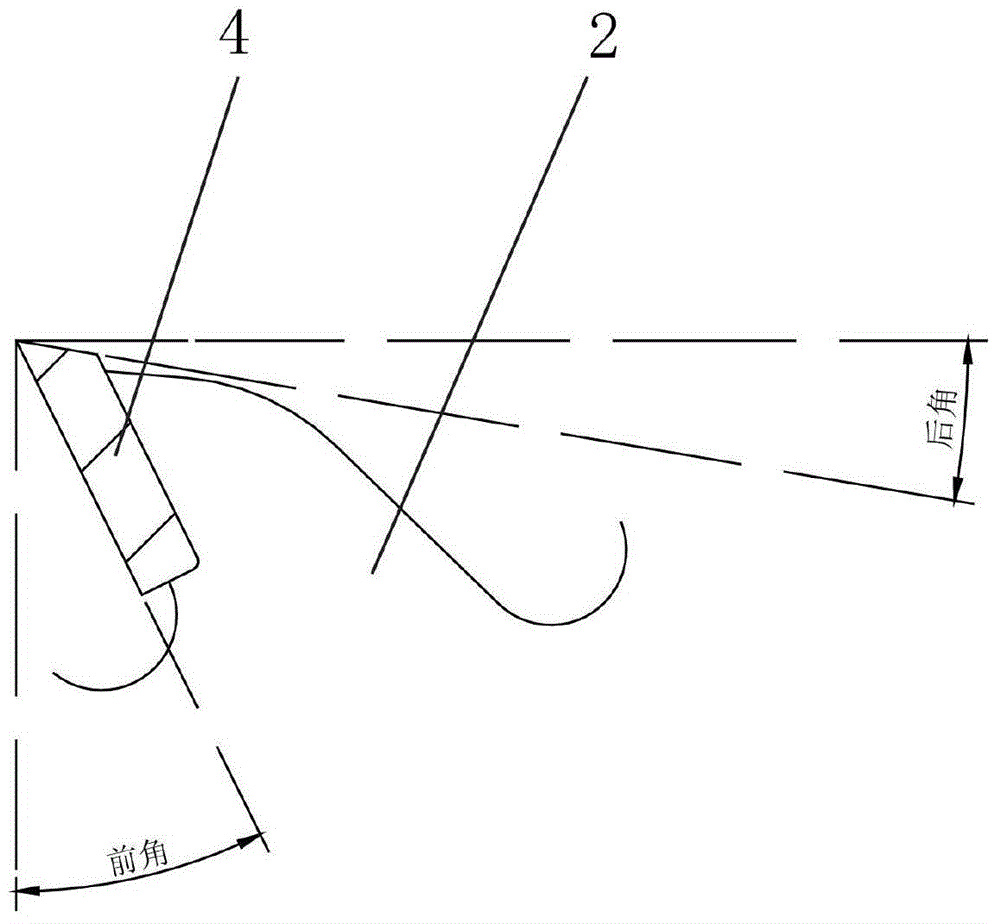

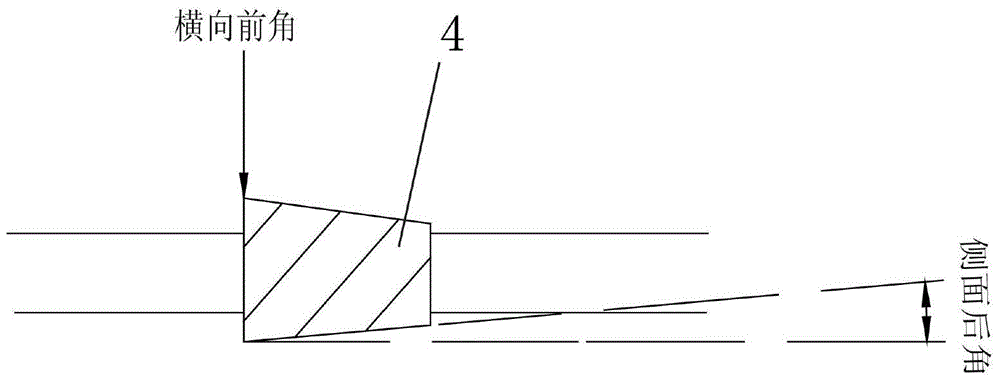

[0018] like figure 1 As shown, the saw blade for preventing cutting edge chipping includes a disc-shaped base body 1 and serrations 2 uniformly distributed on the outer circumference of the base body. A central hole 3 is provided at the center of the base body 1. The base body 1 An expansion groove 5 between the two serrations 2 is also provided on the outer circumference of the sawtooth 2, a cutter head 4 is installed on the serration 2, the front angle of the cutter head 4 is set to 1°~3°, and the rear angle is set to 14° to 16°, the lateral rear angle is set to 1° to 2°, the apex inclination angle is set to 4° to 6°, the lateral radial angle is set to negative 2°, and the lateral rake angle is set to 0°.

[0019] The base body 1 closely fits with the saw shaft through the central hole 3 thereon, ensuring cutting precision.

[0020] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com