Porous material nozzle with adjustable air permeability

A technology of porous material and porous material is applied in the field of nozzle structure of air flotation system, which can solve the problem that the air permeability of porous material nozzle cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

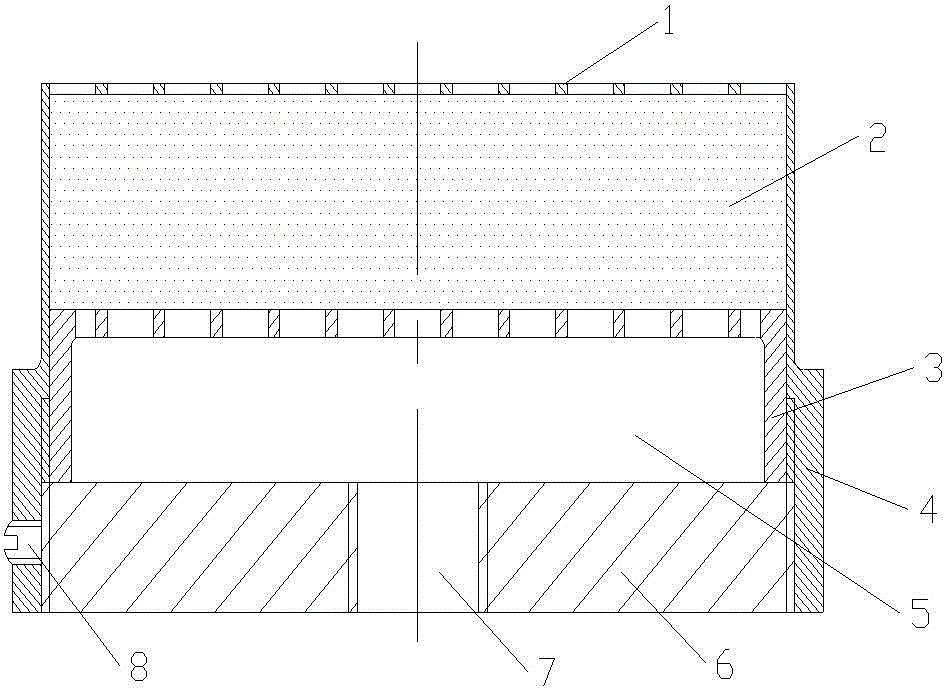

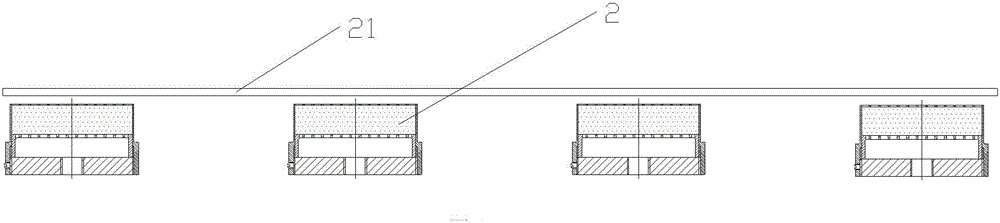

[0017] see figure 1 and figure 2 , the porous material nozzle with adjustable air permeability includes a cylindrical tubular shell 4, one end of the shell 4 is a closed end, the end face of the closed end is uniformly provided with end face pores, and the other end of the shell 4 is an open end; the closed end of the shell 4 A flexible porous material 2 is installed inside.

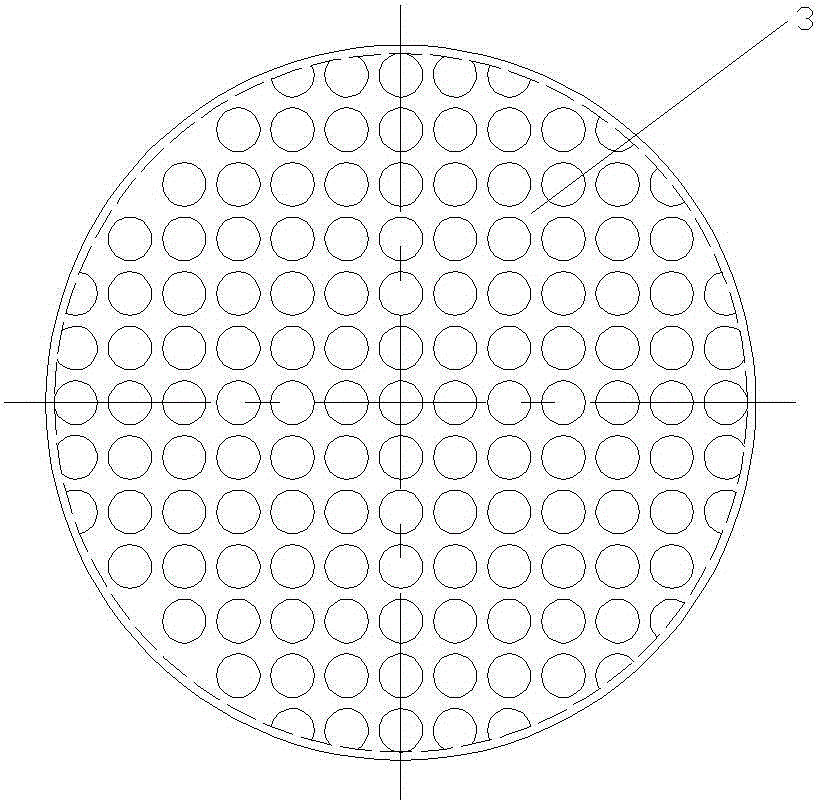

[0018] A pressure plate 3 is installed in the housing 4 corresponding to the flexible porous material 2, the pressure plate 3 is in the shape of a bottle cap, and vent holes are evenly distributed on its axial closed end; between the radial side wall of the pressure plate 3 and the inner wall of the housing 4 To cooperate. The end face diameter of shell 4 is φ 25.5mm, the hole pitch of end face air hole is 2.5mm, the diameter φ 1.6mm of end face air hole, the hole pitch of air hole on the pressure plate is 3mm, the diameter φ 2.5mm of air hole. The open end of the shell 4 is connected to the bulkhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com