Heating pipe with internal and external heating function

A technology of internal and external heating and heating tubes, applied in the field of heating tubes, can solve the problems of difficult precise control, low safety, uneven water temperature, etc., and achieve the effects of easy control, increased heating speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

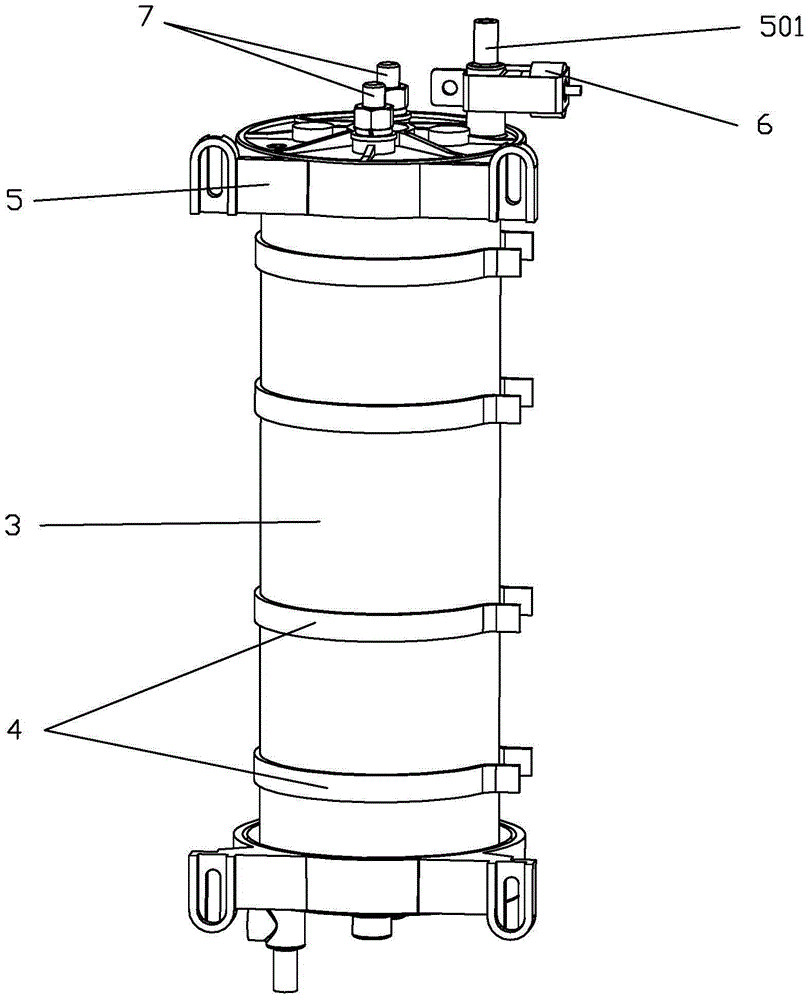

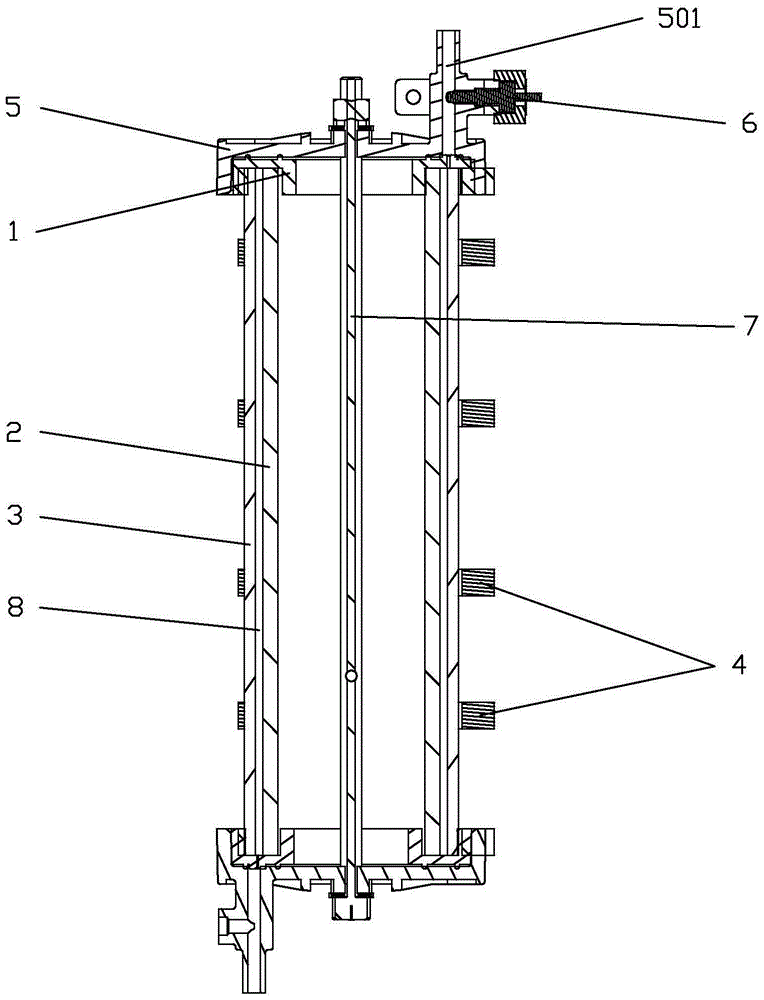

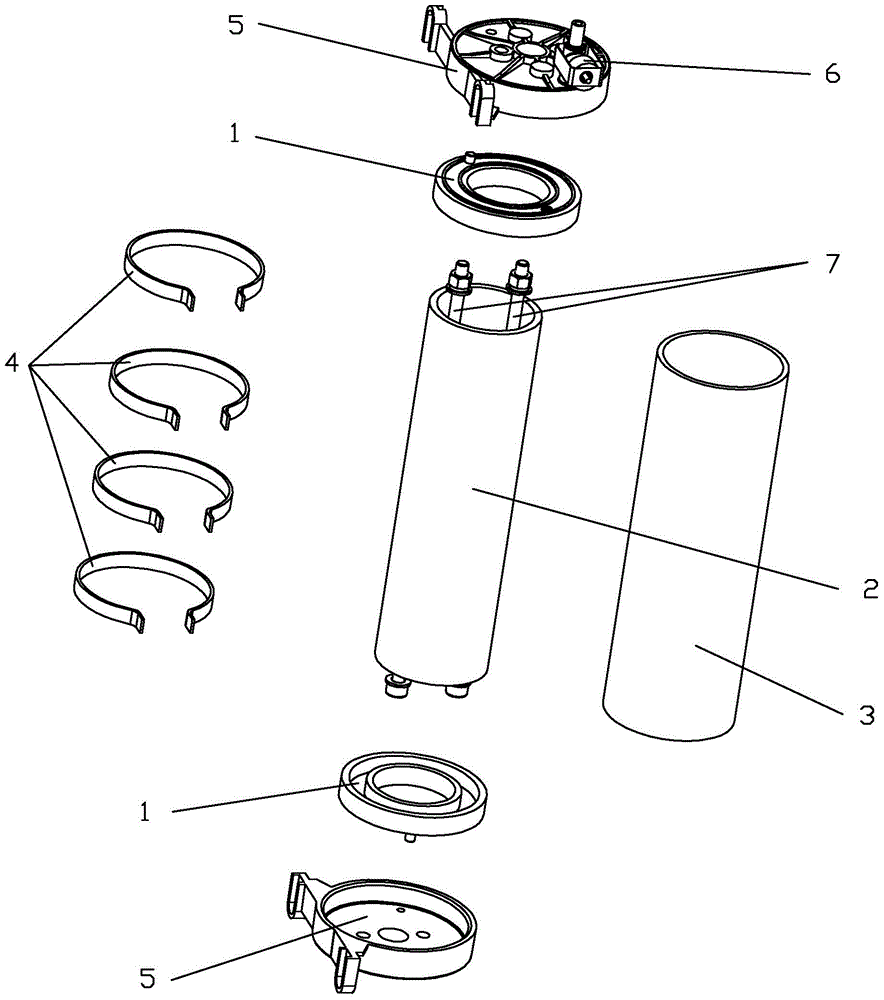

[0020] refer to Figure 1~Figure 7 , a heating tube for internal and external heating, comprising a glass tube and end caps 1 located at both ends of the glass tube, the two end caps 1 are locked and fixed by bolts 7 and nuts, and the end cap 1 is provided with a Adapted groove 101, the glass tube includes an inner tube 2 and an outer tube 3, the inner tube 2 and the outer tube 3 are spaced apart to form a water flow channel 8, and the two end caps 1 are provided with The water flow hole 102 connected to the water flow channel 8, the outer surface of the outer tube 3 is provided with a heating sheet 4, the heating sheet 4 is attached to the outer wall of the outer tube 3, and the heating sheet 4 can be arranged in a ring-shaped wrapping Covering the outer tube 3, the inner surface of the inner tube 2 is provided with a nano-resistance heating film.

[0021] In this embodiment, preferably, four heating sheets 4 are provided and arranged at even intervals. Four heat generating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com