Rapid design method of dilute acetone distillation industry dynamic optimization control layer output constraint

A technology of output constraints and dynamic optimization, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as long time consumption, and achieve the effect of ensuring feasibility and solving speed with short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

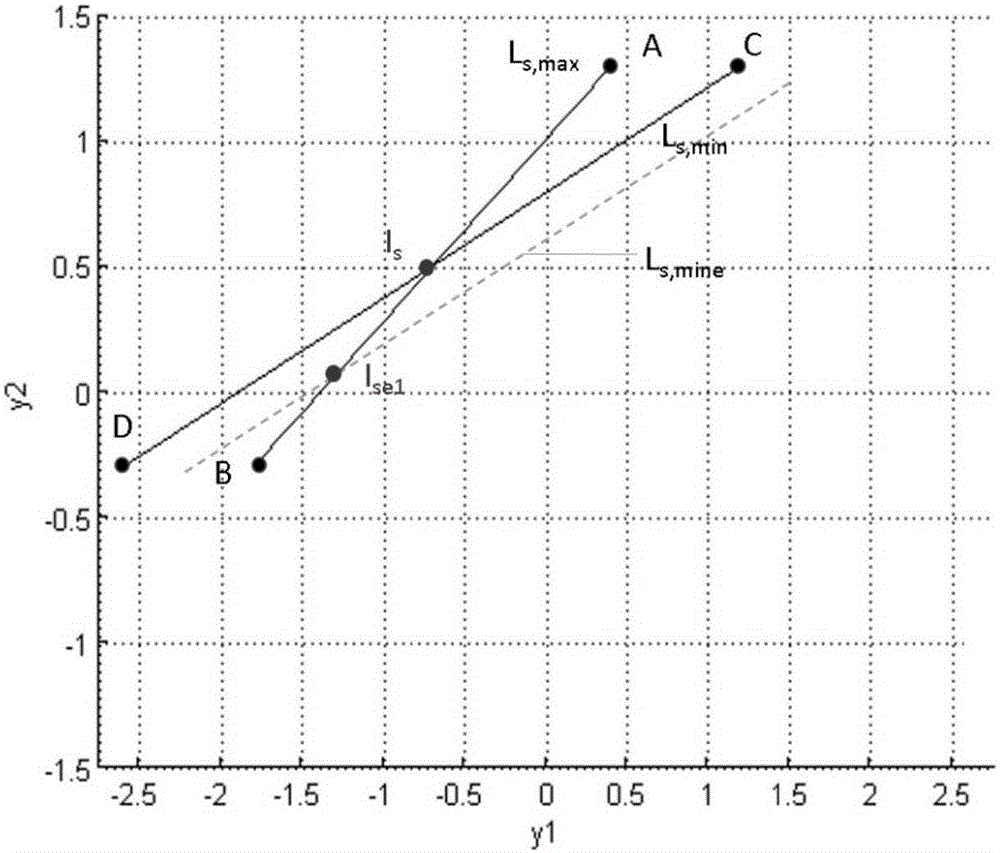

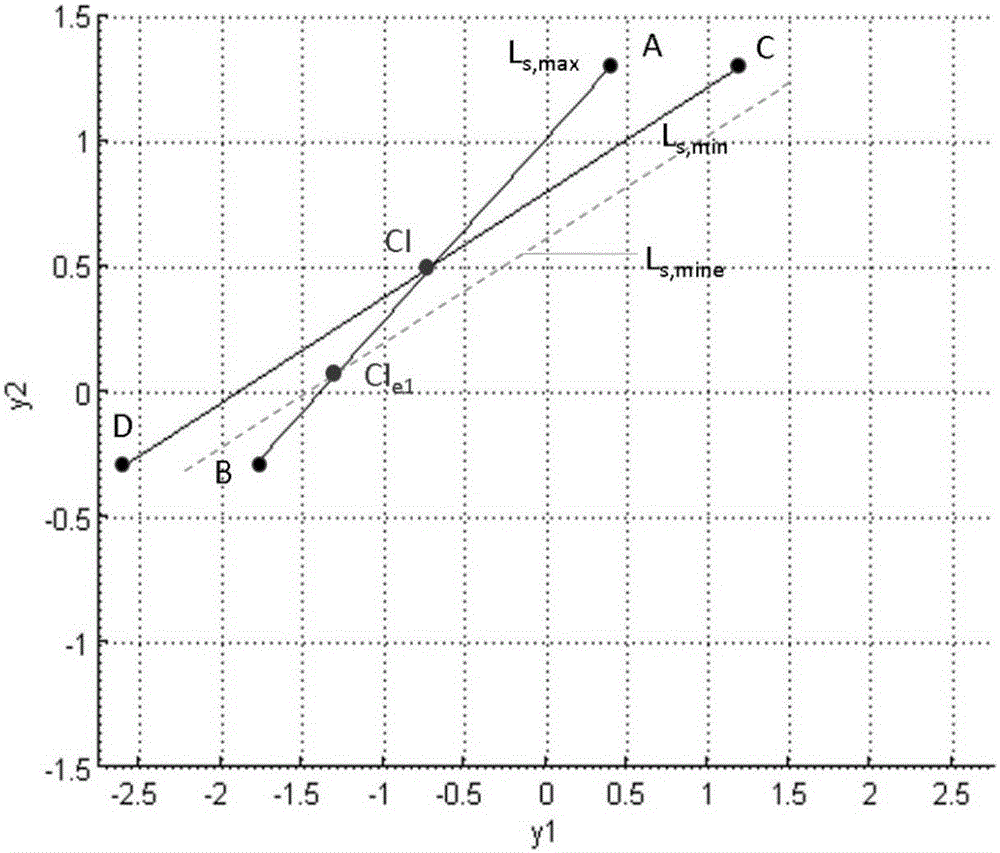

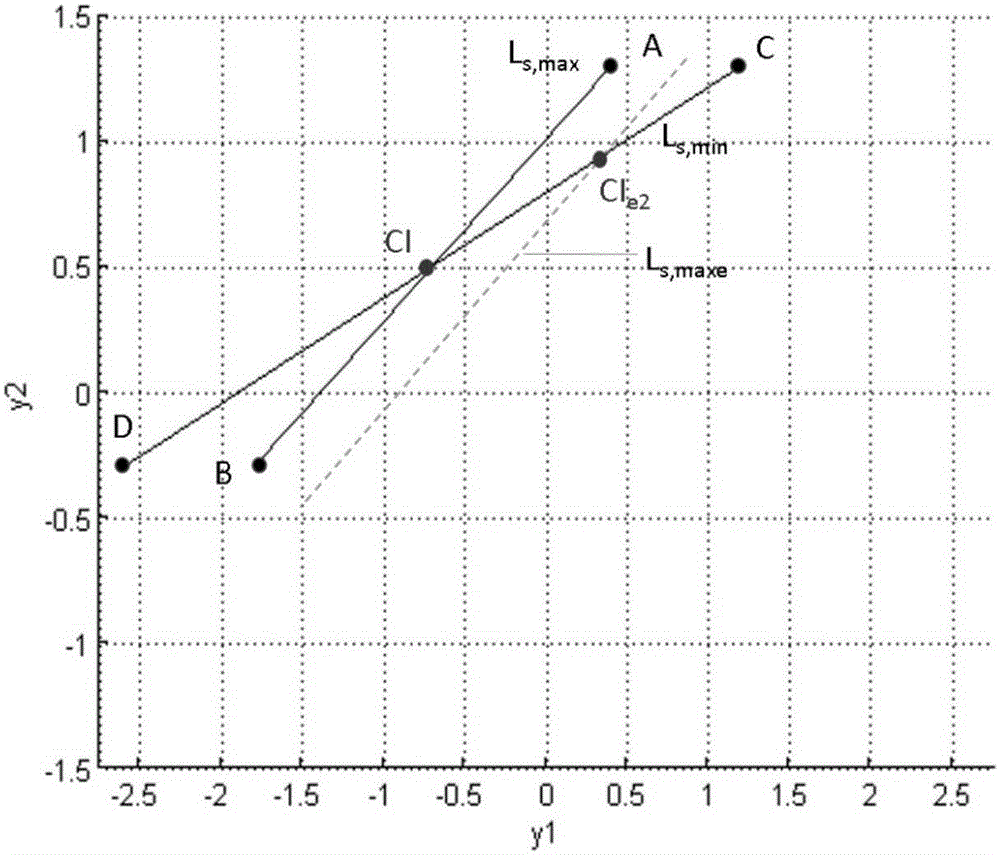

[0058] The following is a detailed description of the rapid design method for the dynamic optimization control layer output constraints of the propylene ketone distillation industry in the present invention in conjunction with the accompanying drawings.

[0059] A rapid design method for dynamic optimization control layer output constraints in the distillation industry of propylene glycol, including:

[0060] Step 1, aiming at the industrial model predictive control system for distilling propylene glycol with double-layer structure, the gain model of the steady-state optimization layer of the model predictive controller is obtained as follows:

[0061] y=Gu+G d d

[0062] In the formula: y is the n×1-dimensional system output, y∈SOC;

[0063] G is an n×m dimensional process gain matrix;

[0064] u is an m×1-dimensional system input variable, u∈SIC;

[0065] G d is an n×p-dimensional interference gain matrix;

[0066] d is the system disturbance variable of p×1 dimension,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com