High-resolution implantable micro-vibration monitoring implementation method

A vibration monitoring and high-resolution technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as economic bottlenecks, high team requirements, and expensive monitoring components, and achieve high efficiency of data processing platforms , high accuracy of data acquisition, and the effect of stabilizing DC power supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0036] The invention is mainly oriented to micro-vibration control engineering, involving fields including electronics industry, precision manufacturing, aerospace, astronomical optics, military weapons, etc. The main requirement of micro-vibration control engineering in these industries is that the vibration level of the vibration control object is as high as sub-micron level, the controlled object is small in size, light in weight, and has the characteristics of long-term continuous operation, so the vibration control process needs Continuous monitoring is carried out while also ensuring that the monitoring process itself does not have adverse vibration effects.

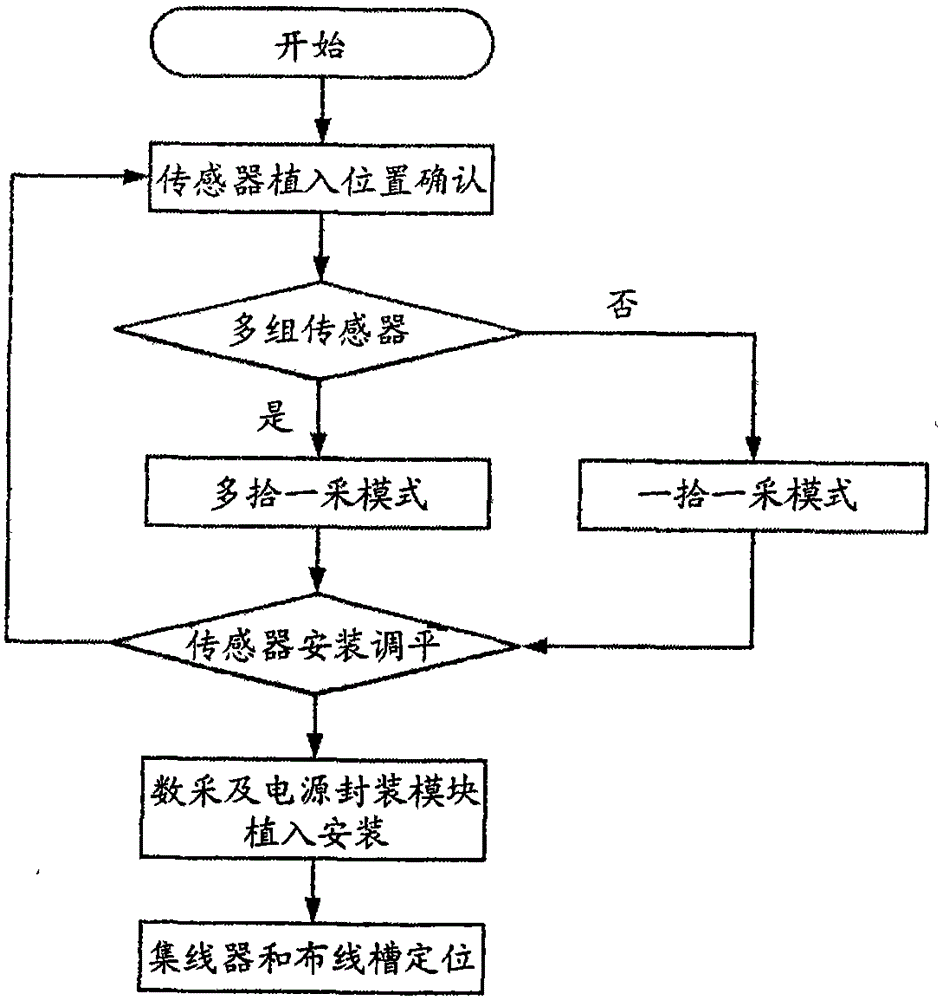

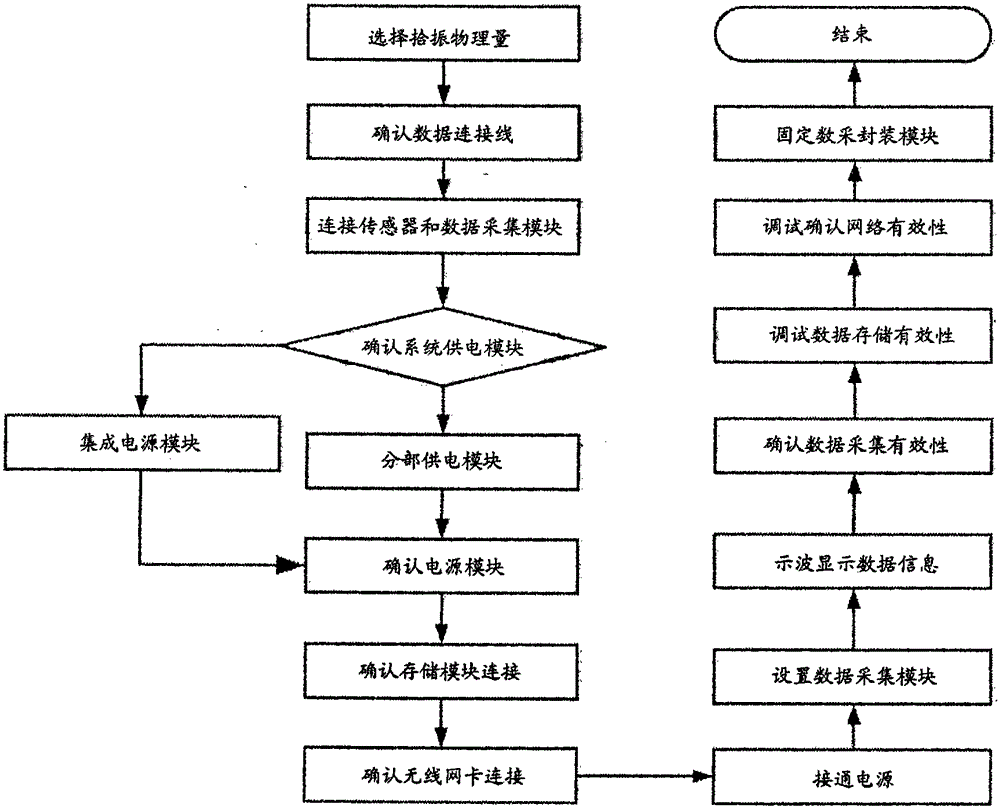

[0037] figure 1 It is a flowchart of the implementation stage of the MEMs sensor and data acquisition configuration modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com