Barrel type radiation and convection heat exchanger and heat exchange treatment method thereof

A heat exchanger and barrel type technology, which is applied in the field of air conditioning technology and heat exchange end products of air conditioning systems, achieves the effects of convenient installation and use, enhanced air convection, and no blowing feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

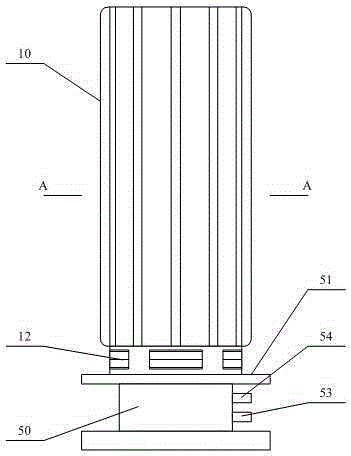

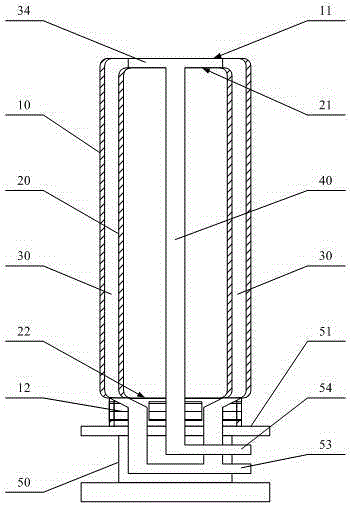

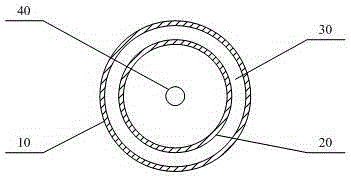

[0037] The invention provides a cylindrical radiation convection heat exchanger, figure 1 A schematic diagram of the overall structure of the cylindrical radiation convection heat exchanger of the present invention is shown, figure 2 It shows the schematic diagram of the vertical cross-sectional structure of the cylindrical radiation convection heat exchanger of the present invention, image 3 It shows that the cartridge type radiation convection heat exchanger of the present invention is in figure 1 The cross-sectional view at position A-A in the center. Such as Figure 1~3 As shown, the cylindrical radiation convective heat exchanger includes a vertically arranged cylindrical heat conduction shell 10 , and a heat conduction inner cylinder 20 is arranged vertically and coaxially inside the cylindrical heat conduction shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com