Disc Magnetic Connection Chemical Sliding Vane Pump

A magnetic connection and sliding vane pump technology, which is applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve parts processing, high assembly precision requirements, many magnetic connection parts, disassembly and assembly Maintenance is cumbersome and other problems, to achieve the effect of stable operation, simple processing and long maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

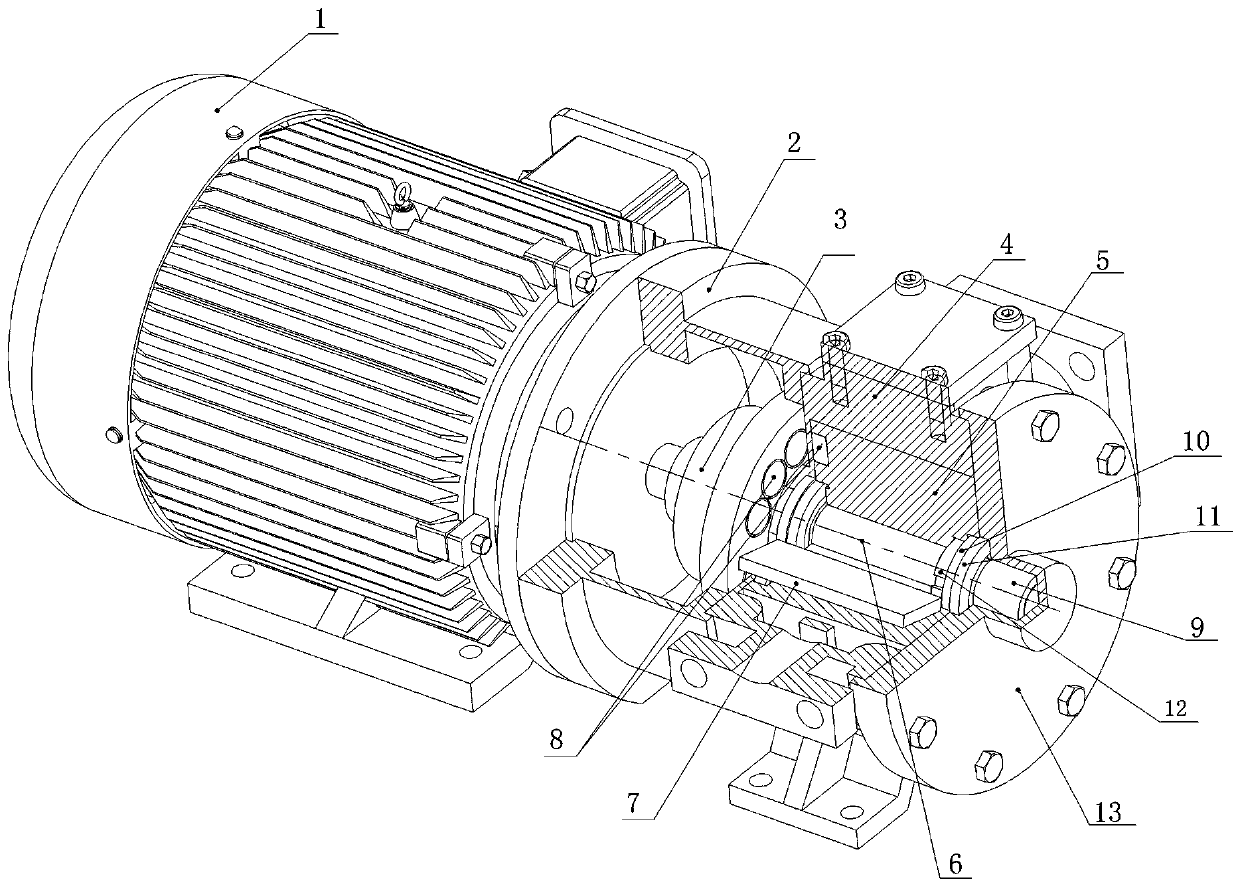

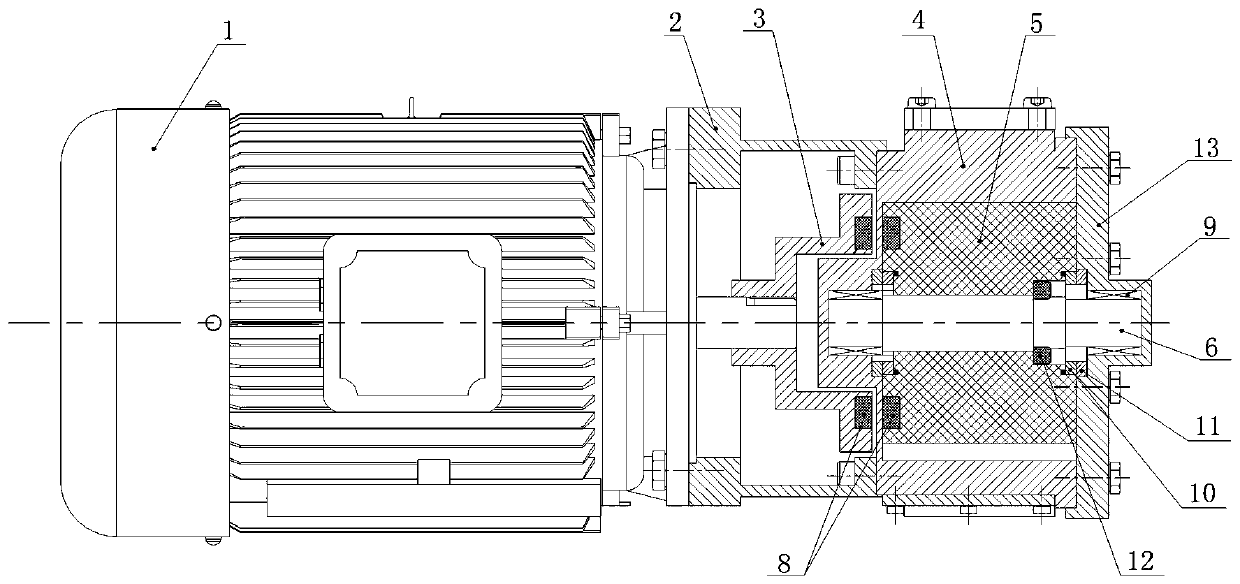

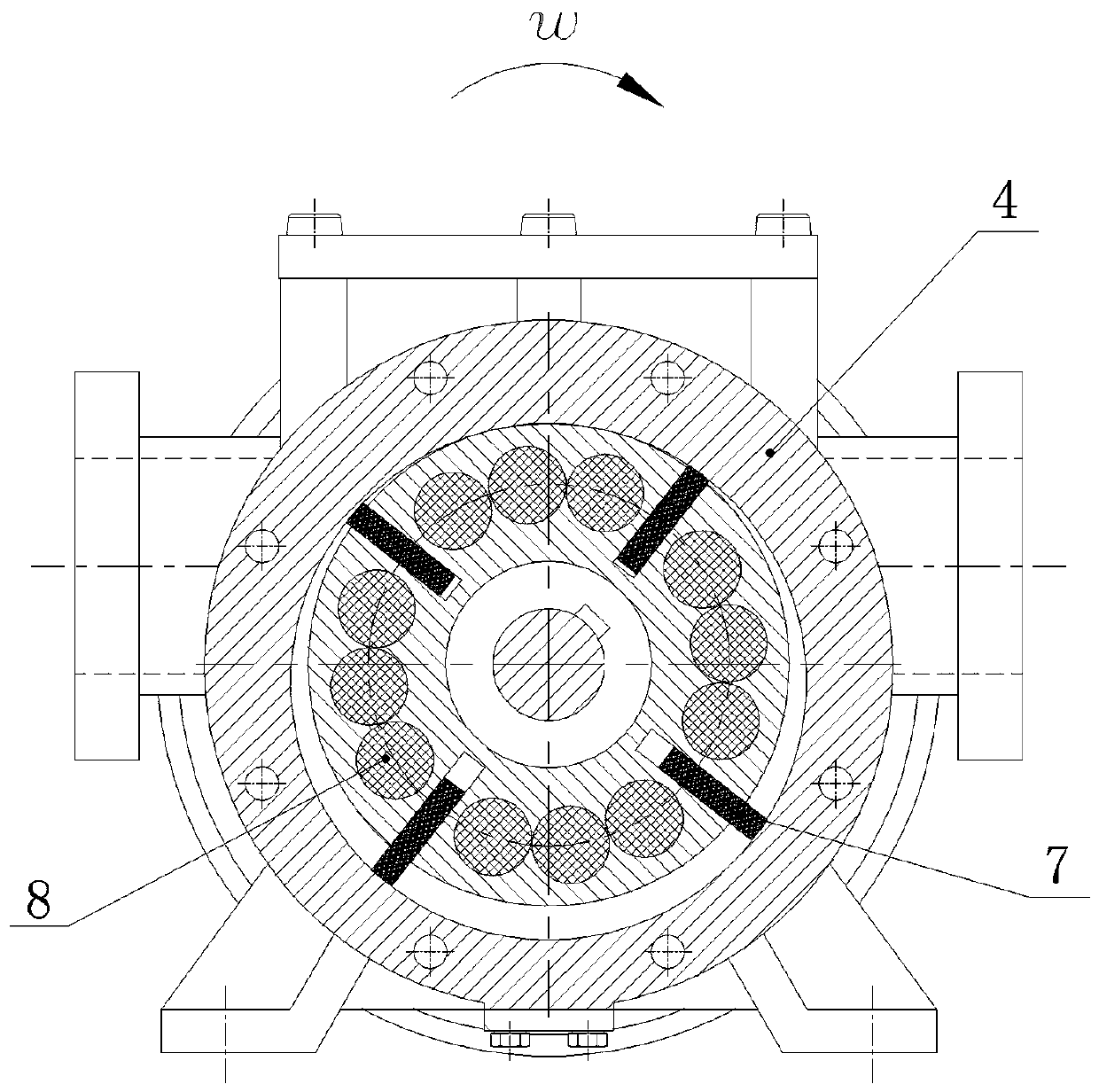

[0015] See attached figure 1 , a disc-type magnetic connection chemical sliding vane pump, including a motor (1), a connecting disc (2), a disc-type outer magnetic rotor (3), a pump body with an eccentric inner cavity (4), and an inner magnetic rotor with a slot (5 ), pump shaft (6), sliding plate (7), round magnet (8), sliding bearing (9), hard alloy moving ring (10), silicon carbide stationary ring (11), round nut (12), Pump back cover (13) and other components.

[0016] Connect and fix the disc-type outer magnetic rotor (3) inlaid with the circular magnet (8) with the output shaft of the motor (1).

[0017] The circular magnet (8) is embedded in the magnetic rotor (5) in the groove, which saves the mechanical space required by the ring-connected magnetic pump; then the hard alloy moving ring (10) and the pump shaft (6) are installed in sequence The inner magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com