Multi-stage perforation redundant ignition control device

A technology of ignition control and ignition device, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of ignition failure, high rework cost, complicated circuit design, etc., and avoid accidental well closure and ignition. Easy to operate and ensure smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

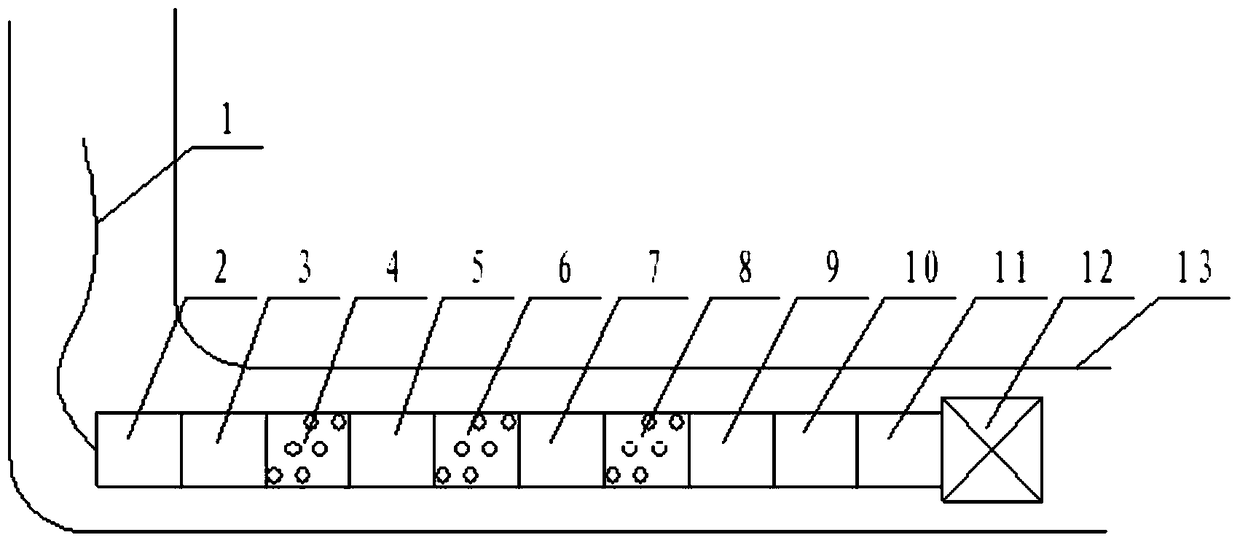

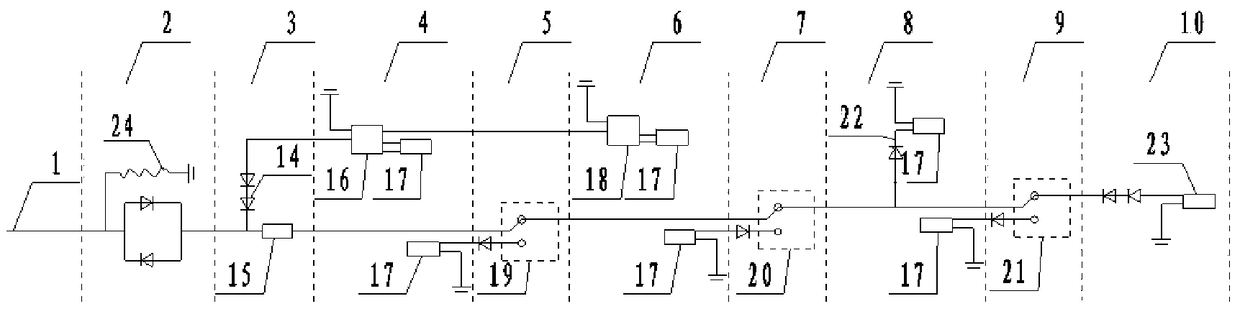

[0011] In the present invention, a plurality of perforating guns for shooting out formations and corresponding multi-stage ignition devices for circuit control are sequentially connected in series between the depth calibration instrument 2 and the setting tool 11 in the operating horizontal wellbore 13. The gun head at the lower end of the depth calibration instrument leads to two parallel lines, one line is connected to the voltage control switch, and the other line is used to connect to the electric selection switch; each voltage control switch is connected with a diode; each voltage control switch is connected in series until the bridge plug igniter is connected , each electric selection switch is connected in series, the top is connected with a resistor, and each diode is connected in series until it is connected to a single-core cable 1; each voltage-controlled switch and each electric selection switch is connected with an electric detonator, and the electric detonator is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com