A two-way limit mechanism of laminated U-shaped steel plates

A two-way limit and U-shaped technology, which is applied to building components, earthquake resistance, etc., can solve the problems that the tensile capacity of the limit device cannot be exerted, the hard steel U-shaped steel plate is brittle, and the waste of resources is not easy to yield. , improve the anti-seismic performance, and save the effect of the limiter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1, directly used on the side of the rubber bearing:

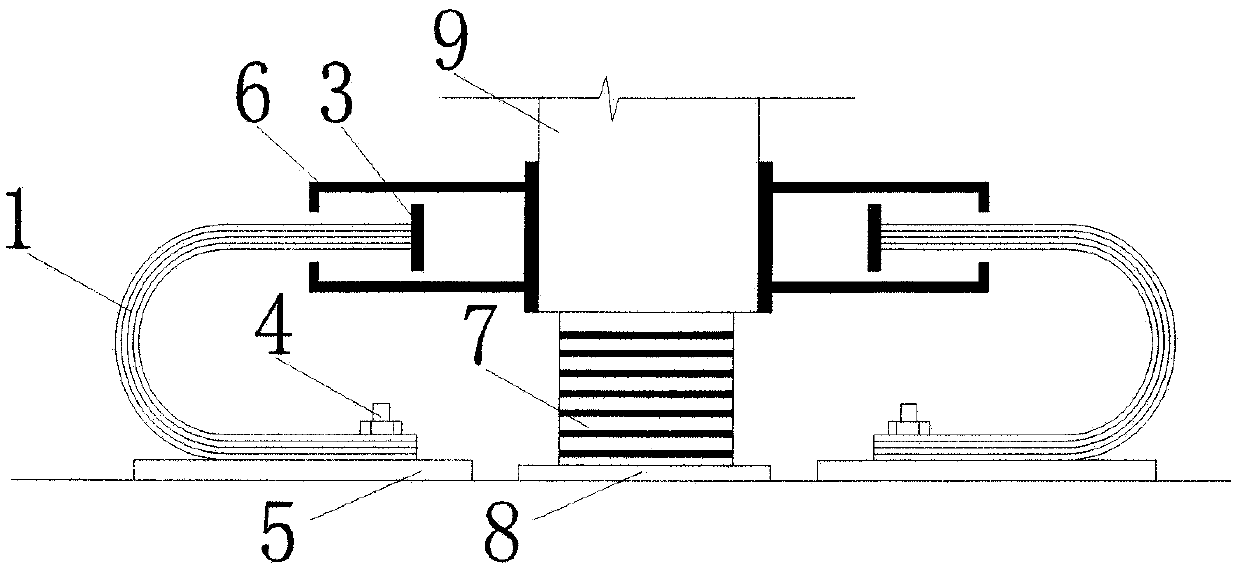

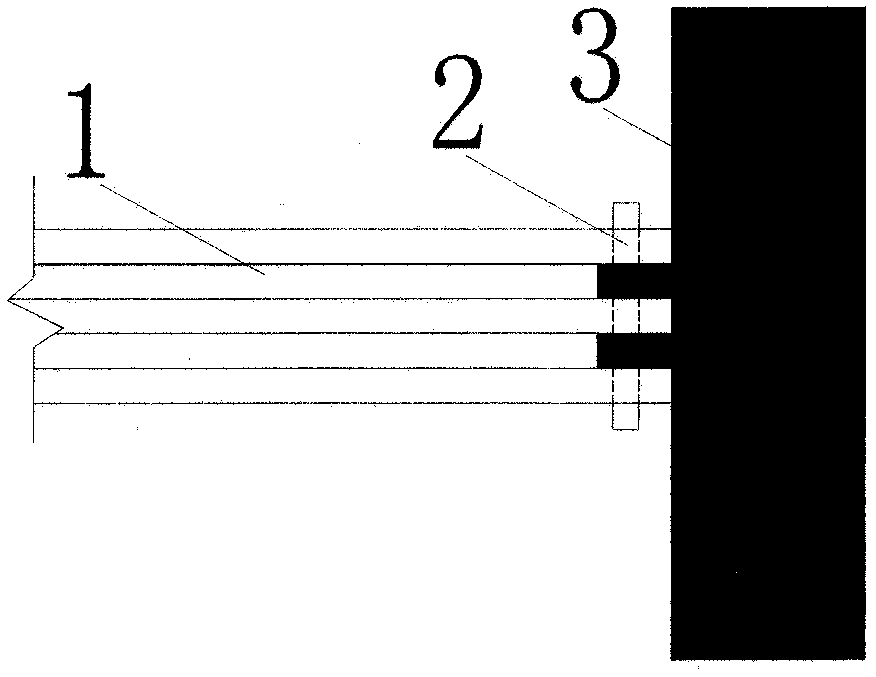

[0021] Such as figure 1 As shown, a bidirectional limit mechanism of laminated U-shaped steel plates includes laminated U-shaped steel plates (1), U-shaped steel plate fixing plates (5), push-pull plates (3), push-pull grooves (6) and the like.

[0022] (1) Fix the push-pull groove (6) on the side of the upper structural column of the rubber bearing. If the column is a steel column, the push-pull groove can be directly welded to the column. If the column is a concrete column, it can be pre-embedded on the column Connect the bolts, and fix the connection slots with bolts.

[0023] (2) The push-pull plate (3) is fixed on the horse-toothed bracket of the upper arm of the laminated U-shaped steel plate (1) by its connection key with the connection bolt (2).

[0024] (3) Put the upper arm of the laminated U-shaped steel plate (1) together with the push-pull plate (3) into the connection groove (6) from the side ...

example 2

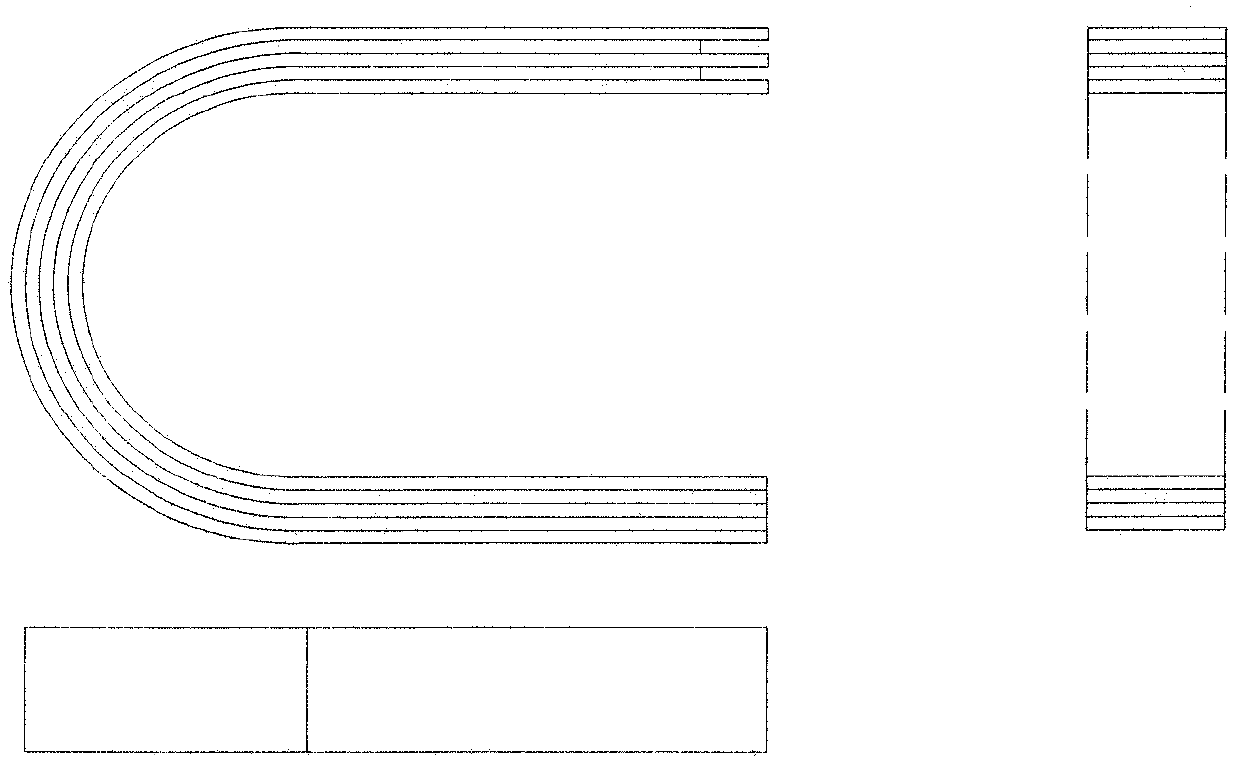

[0027] Example 2, installed on the outside of the entire building:

[0028] Such as figure 2 As shown, when the space of the seismic isolation layer is limited, the laminated U-shaped steel plate bidirectional limiting mechanism can be installed on the outside of the entire building. The board (5) is pre-embedded on the foundation outside the building. Other connections are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com