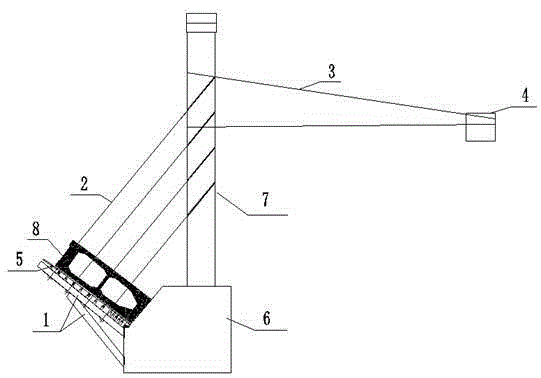

Construction method of cable-stayed combined support for construction of first segment of suspended-pouring arch bridge

A construction method and combined support technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that cannot be used, and achieve the effects of good linear control, strong support capacity, and long pouring sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

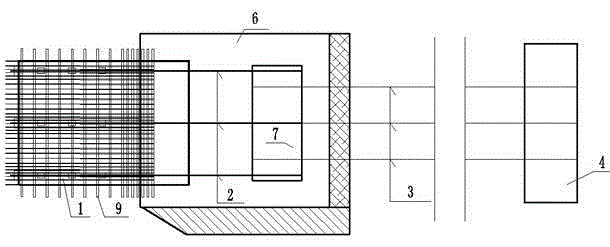

[0041] The specific construction method steps are as follows:

[0042] (1) Pre-embedded channels: pre-embedded steel plates in the abutment, longitudinally supporting the welding points of the girders; pre-embedded channels in the junction pier, anchored by positive buckle cables and anti-tension anchor cables; pre-embedded channels in the cap, anchored by anti-tension anchor cables Via.

[0043] (2) Installation of longitudinal support girder: release the welding side line of longitudinal support girder, and the longitudinal girder is welded to the abutment in the form of cantilever corbel. Three pieces are arranged in the direction of the bridge, and each piece contains a triangular bracket composed of a longitudinal beam and a diagonal brace. During installation, a total station should be used to determine the centerline offset and elevation of each support beam.

[0044] (3) Leveling pipe installation: Weld the leveling steel pipe on the longitudinal girder, and the leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com