Method for manufacturing low-sugar low-alcohol-concentration Kbac beverage

A production method and technology of kvass, applied in the preparation of alcoholic beverages, etc., can solve the problem of being unable to drink kvass beverages with sugar content, and achieve the effect of reducing alcohol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

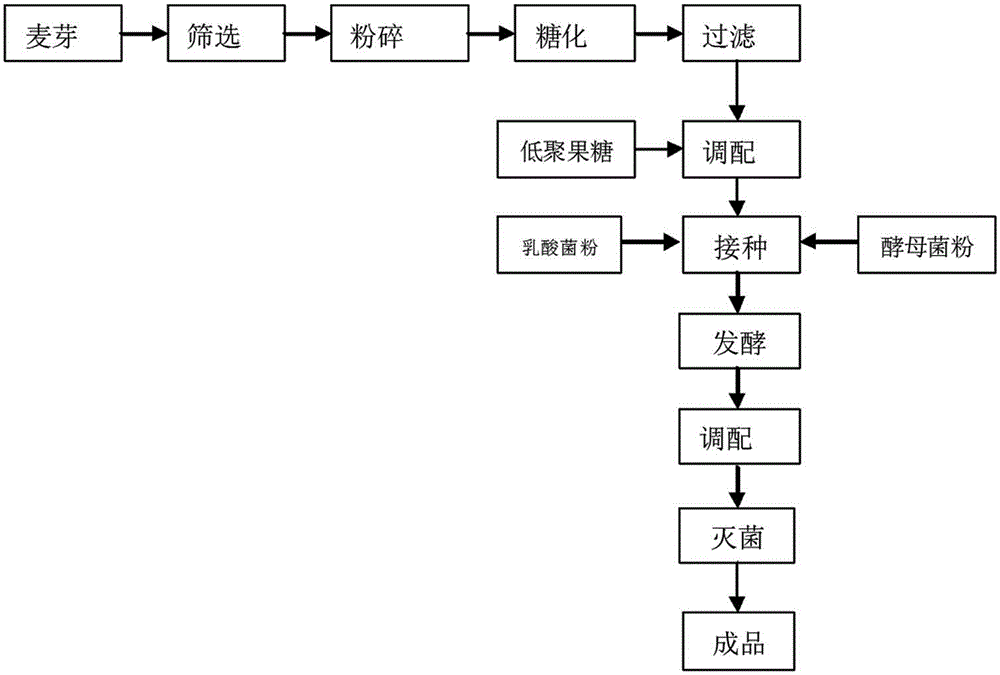

Method used

Image

Examples

Embodiment 1

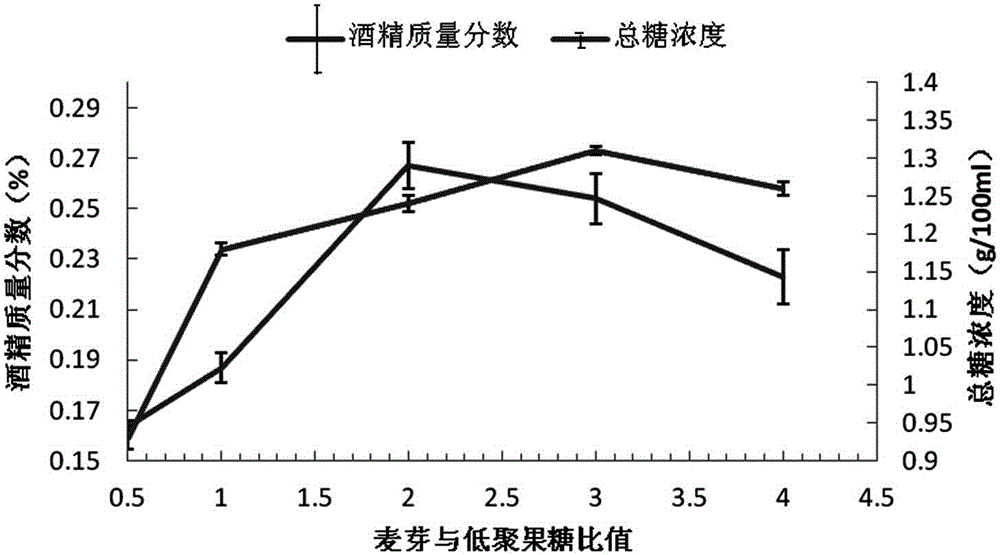

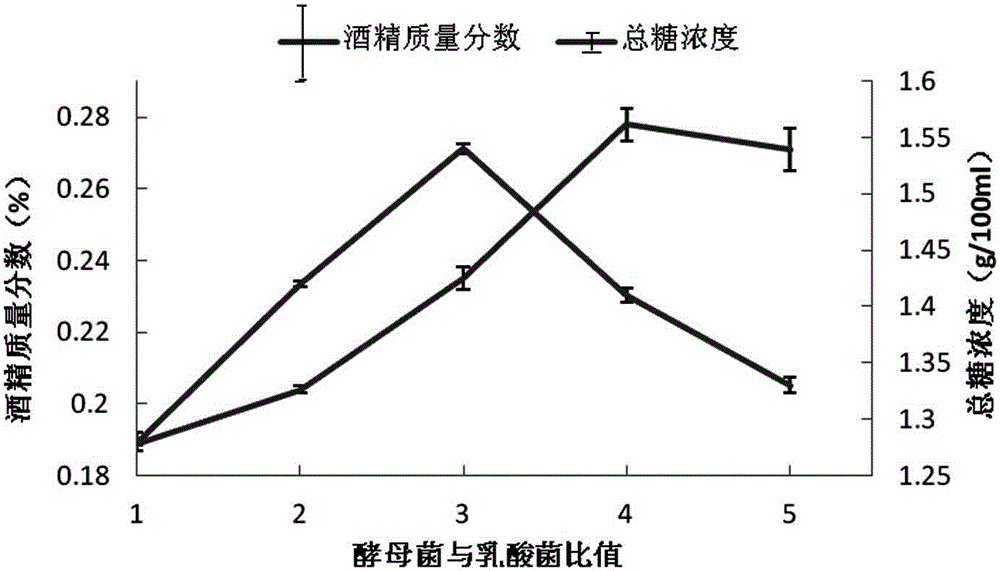

[0024] A method for making a low-sugar and low-alcohol kvass beverage, the method comprising the following steps: (1) selecting mature and plump barley malt, pulverizing the barley malt, passing through a 60-mesh sieve, and putting the barley malt and water into a fermentation tank Saccharification is carried out in the medium, the mass of barley malt and water is 1:3. Saccharify in a water bath at 72°C for 90 minutes, boil the barley wort for 3 minutes, then cool to room temperature, and then filter through 8 layers of gauze to obtain the barley wort filtrate; (2) Add fructooligosaccharides to the filtered barley wort, The mass ratio of barley malt and fructo-oligosaccharides is 5:4, after deployment, inoculate lactic acid bacteria and yeast in the fermenter, the mass ratio of yeast and lactic acid bacteria is, yeast: lactic acid bacteria=2:1, the mass parts of inoculum After inoculation, ferment in a fermenter at a fermentation temperature of 30° C. and a fermentation time o...

Embodiment 2

[0026] The mass ratio of barley malt to fructooligosaccharide is barley malt:fructooligosaccharide=1.53:1, the mass ratio of yeast to lactic acid bacteria is yeast:lactic acid bacteria=2.16:1, and other steps are the same as in Example 1.

Embodiment 3

[0028] A method for making a low-sugar and low-alcohol kvass beverage, the method comprising the following steps: (1) selecting mature and plump barley malt, pulverizing the barley malt, passing through a 60-mesh sieve, and putting the pulverized barley malt and water into Carry out saccharification in a fermenter, the mass ratio of barley malt and water is 1:2, saccharify in a 65°C water bath for 100 minutes, boil the wort for 2 minutes, then cool to room temperature, and then filter through 8 layers of gauze to obtain the wort filtrate (2) add fructooligosaccharide in the wort after filtering, the mass ratio of barley malt and fructooligosaccharide is 1:2, after deployment, inoculate lactic acid bacteria and saccharomycete in fermenter, the mass ratio of saccharomycete and lactic acid bacterium For, yeast: lactic acid bacteria = 1:1, the inoculation amount of yeast and lactic acid bacteria is 1% by mass, and fermented in a fermenter after inoculation, the fermentation tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com