Preparation method of nitrogen doped carbon based quantum dot

A technology of carbon-based quantum dots and nitrogen doping, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of less waste liquid discharge, environmental protection, influence on the purity of synthesized carbon-based quantum dots, and short reaction time. It is easy to achieve The effects of purification, short preparation cycle and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

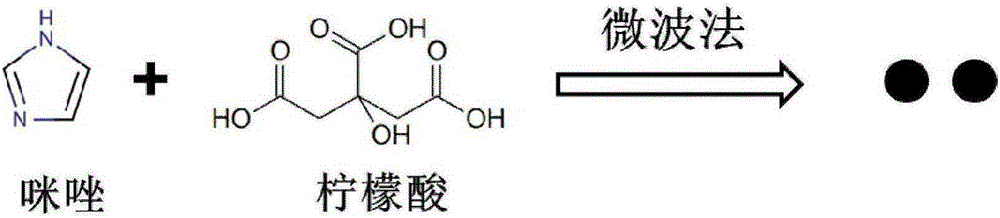

[0038] Further, the preparation method of nitrogen-doped carbon-based quantum dots comprises the following steps:

[0039] (1) Mix citric acid and imidazole compounds uniformly at a molar ratio of 1:0.5 to 1:12, wherein citric acid is a carbon source, and imidazole compounds are a nitrogen source.

[0040] (2) Heat the mixed material in step 1 with a microwave higher than 100W for 1-15 minutes to obtain a brown-black solid containing carbon-based quantum dots. According to the selection and adjustment of the reaction raw materials, the color of the carbon-based quantum dots obtained by microwave carbonization may be different, but this does not affect the realization of the purpose of the invention. Preferably, in order to facilitate the microwave treatment, the mixed material can be selected to be placed in a microwave oven for microwave treatment, and the microwave energy required for controlling the reaction material per unit volume (per liter) is not less than 1000KJ, and ...

Embodiment 1

[0047] Take 3g of citric acid and 0.9378g of imidazole solids (the molar ratio of citric acid and imidazole is 1:1) and put them in a beaker, stir them with a glass rod for physical mixing, put the mixed citric acid and imidazole directly in the microwave oven, set the microwave oven The power is 500W, and the reaction time is 3 minutes. After the reaction is completed, a brown-black solid is obtained, which contains the target nitrogen-doped carbon-based quantum dots.

[0048] Further, the product is purified. Add secondary water to the brown-black solid beaker, ultrasonically disperse for 30 minutes, vacuum filter the solution, and rinse with secondary water several times to remove unreacted citric acid and imidazole soluble in water, and obtain nitrogen-doped carbon-based Quantum dot filter cake. Finally, the filter cake was dried in a vacuum oven at 60°C for 1 hour to obtain pure nitrogen-doped carbon-based quantum dot solids.

Embodiment 2

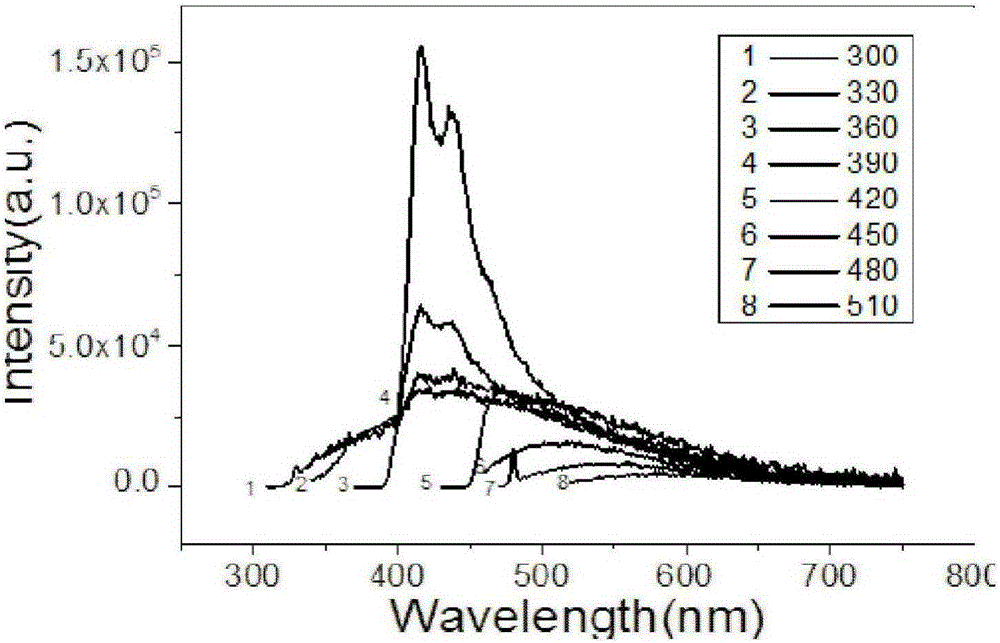

[0050] Take 3g of citric acid and 2.8594g of imidazole solids (the molar ratio of citric acid and imidazole is 1:3) and put them in a beaker, stir them with a glass rod for physical mixing, put the mixed citric acid and imidazole directly in the microwave oven, set the microwave oven The power is 500W, and the reaction time is 3min. After the reaction is completed, a brown-black solid is obtained. Add secondary water to the beaker, ultrasonically disperse for 30 minutes, vacuum filter the solution, and rinse with secondary water several times to remove unreacted citric acid and imidazole soluble in water, and obtain nitrogen-doped carbon-based quantum dot filter cake. Finally, the filter cake was dried in a vacuum oven at 60°C for 1 hour to obtain pure nitrogen-doped carbon-based quantum dot solids. The UV absorption spectrum and fluorescence emission spectrum were tested as follows: figure 2 with image 3 , the results of specific nitrogen content and fluorescence luminous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com