Preparation method of minodronic acid for treating osteoporosis

A technology for minodronic acid and osteoporosis, applied in the field of medicine and chemical industry, can solve the problems of slow reaction speed, many by-products, harsh conditions, etc., and achieve the effects of less by-products, improved yield, and improved reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

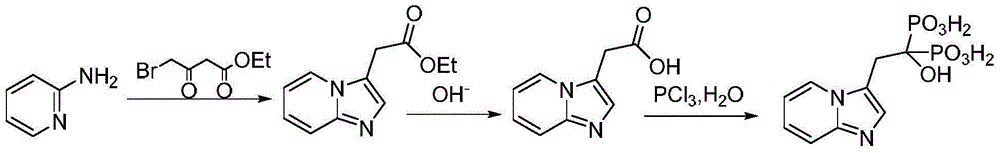

Image

Examples

Embodiment 1

[0039] A preparation method of minodronic acid for treating osteoporosis, the method comprises the following steps:

[0040](1) Add 10.83g (51.8mmol) of 4-bromo-ethyl acetoacetate and 0.97g of reaction accelerator M0.97g into a three-necked flask with a mixed solvent of water and 1,4-dioxane in 100ml, and stir at room temperature for 15 minutes, then add 5.36g (57mmol) of 2-aminopyridine and stir the reaction at 70°C for 3.5 hours, monitor by TLC until the reaction of ethyl 4-bromo-acetoacetate is complete, filter, concentrate under reduced pressure, add water, extract with ethyl acetate (50mL × 3 times), washed with saturated brine (50 mL × 3 times), combined the organic phases, removed the solvent under reduced pressure, and dried to obtain 10.17 g of light yellow oil, namely 2-(imidazo[1,2-α]pyridine- 3-yl) ethyl acetate, yield 94.1%, purity 97.9%; wherein, reaction accelerator M is composed of zinc nitrate and glycine with a weight ratio of 7:1, and the mixed solvent is co...

Embodiment 2

[0044] A preparation method of minodronic acid for treating osteoporosis, the method comprises the following steps:

[0045] (1) Add 10.83g (51.8mmol) of 4-bromo-ethyl acetoacetate and 1.08g of reaction accelerator M1.08g into a three-necked flask with a mixed solvent of water and 1,4-dioxane in 100ml, and stir at room temperature for 15 minute, then added 2-aminopyridine 7.31g (77.7mmol) and stirred at 65°C for 3 hours, monitored by TLC until the reaction of 4-bromo-ethyl acetoacetate was complete, filtered, concentrated under reduced pressure, added water, and extracted with ethyl acetate ( 50mL×3 times), combined the organic phases, removed the solvent under reduced pressure, and dried to obtain 10.08g of light yellow oil, which was 2-(imidazo[1,2-α]pyridin-3-yl)ethyl acetate, yield 93.6%, with a purity of 98.2%. Among them, the reaction accelerator M is composed of zinc nitrate and glycine with a weight ratio of 8:1, and the mixed solvent is formed by mixing 10ml of water ...

Embodiment 3

[0049] A preparation method of minodronic acid for treating osteoporosis, the method comprises the following steps:

[0050] (1) 10.83g (51.8mmol) of 4-bromo-ethyl acetoacetate and 0.98g of reaction accelerator M0.98g are added in the there-necked flask of the mixed solvent of 100ml water and 1,4-dioxane, stirred at room temperature for 15 minute, then added 2-aminopyridine 6.09g (64.75mmol) and stirred at 68°C for 4 hours, monitored by TLC until the reaction of 4-bromo-ethyl acetoacetate was complete, filtered, concentrated under reduced pressure, added water, and extracted with ethyl acetate ( 50mL×3 times), the organic phases were combined, and the solvent was removed under reduced pressure to obtain 10.15g of a light yellow oily substance, namely 2-(imidazo[1,2-α]pyridin-3-yl)ethyl acetate, yield 93.9 %, with a purity of 97.9%; wherein, the reaction accelerator M is composed of zinc nitrate and glycine at a weight ratio of 7.5:1, and the mixed solvent is formed by mixing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com