Method used for ultrasonic treatment of waste water

A technology for ultrasonic treatment and waste water, which is applied in the direction of combustion methods, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problems that cannot meet the requirements of sewage treatment, expensive equipment investment and operation costs, and affect the economic benefits of enterprises. Achieve the effects of easy incineration, fast processing speed and improved dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

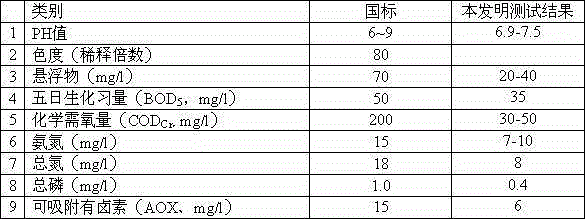

Examples

Embodiment 1

[0019] The present invention in concrete implementation, comprises the following steps:

[0020] (1) Dosing: the method is to put the pulping wastewater into the reactor first, then add the water purifying agent and stir evenly, so that the mass concentration of the water purifying agent in the wastewater is 0.1-25%, and then it is prepared into a wastewater purifying agent mixed solution;

[0021] The water purifying agent is one of polyacrylamide, polyethyleneimine, aluminum sulfate, ferric sulfate or polyferric sulfate;

[0022] (2) Heating reaction: conduct heating reaction on the mixed solution of wastewater purifying agent, so that the temperature of the mixed solution of wastewater purifying agent rises to 25-35°C;

[0023] (3) Ultrasonic reaction: heat and react the mixed liquid of wastewater purifying agent at an ultrasonic power of 0.5-1.2kW / m 3 , the frequency is 50~250kHz, and the ultrasonic response time is 0.5~4h;

[0024] (4) Degradation: After the ultrasonic...

Embodiment 2

[0028] In specific implementation, the present invention can also be realized by the following steps:

[0029] (1) Dosing: the method is to first put the pulping wastewater into the reactor, then add the water purifying agent and stir evenly, so that the mass concentration of the water purifying agent in the wastewater is 0.5-20%, and then it is prepared into a wastewater purifying agent mixed solution;

[0030] The water purifying agent is a mixture made by mixing two of polyacrylamide, polyethyleneimine, aluminum sulfate, ferric sulfate or polyferric sulfate with the same weight;

[0031] (2) Heating reaction: conduct heating reaction on the mixed solution of wastewater purifying agent, so that the temperature of the mixed solution of wastewater purifying agent rises to 28-33°C;

[0032] (3) Ultrasonic reaction: heat and react the mixed liquid of wastewater purifying agent at an ultrasonic power of 0.8-1kW / m 3 , the frequency is 100~200kHz, and the ultrasonic response time...

Embodiment 3

[0037] The present invention can also be realized by the following steps in concrete implementation:

[0038] (1) Dosing: first put the pulping wastewater into the reactor, then add the water purifying agent and stir evenly, so that the mass concentration of the water purifying agent in the wastewater is 0.1-15%, and prepare the mixed liquid of the wastewater purifying agent;

[0039] The water purifying agent is a mixture made by mixing three or more of polyacrylamide, polyethyleneimine, aluminum sulfate, ferric sulfate or polyferric sulfate with the same weight;

[0040] (2) Heating reaction: conduct heating reaction on the mixed solution of wastewater purifying agent, so that the temperature of the mixed solution of wastewater purifying agent rises to 29-30°C;

[0041] (3) Ultrasonic reaction: heat and react the waste water purification agent mixture at an ultrasonic power of 0.9kW / m 3 , the frequency is 150kHz, and the ultrasonic response time is 2h;

[0042] (4) Degrada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com