Packaging device and packaging method of finished tobacco flakes

A technology of packaging equipment and smoke sheets, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., and can solve problems such as waste, inconvenience, and easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the fourth layer of smoke sheet pressing

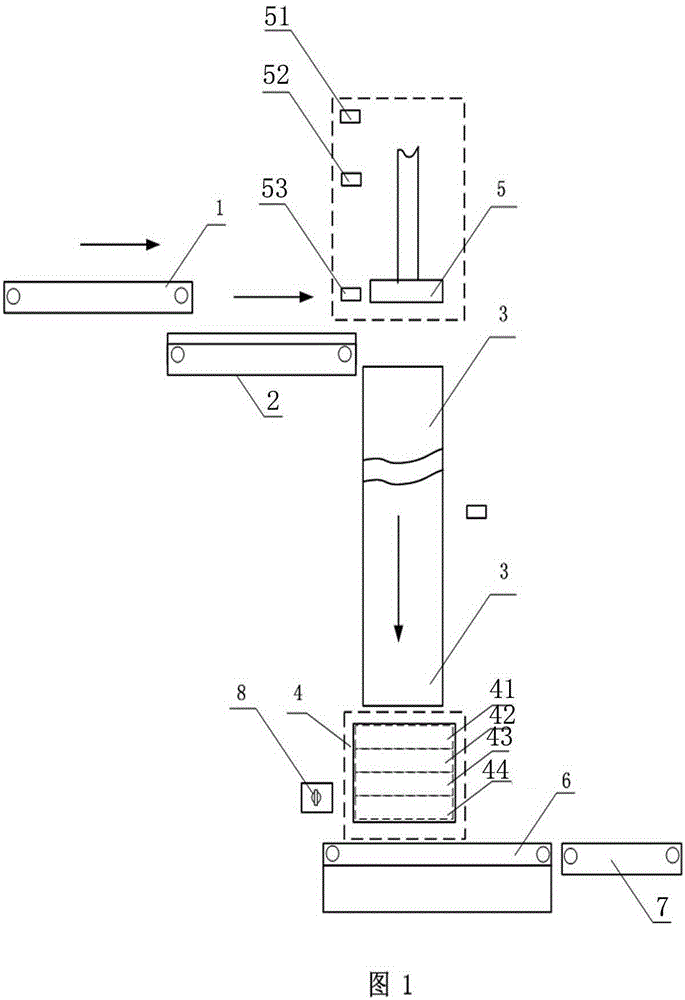

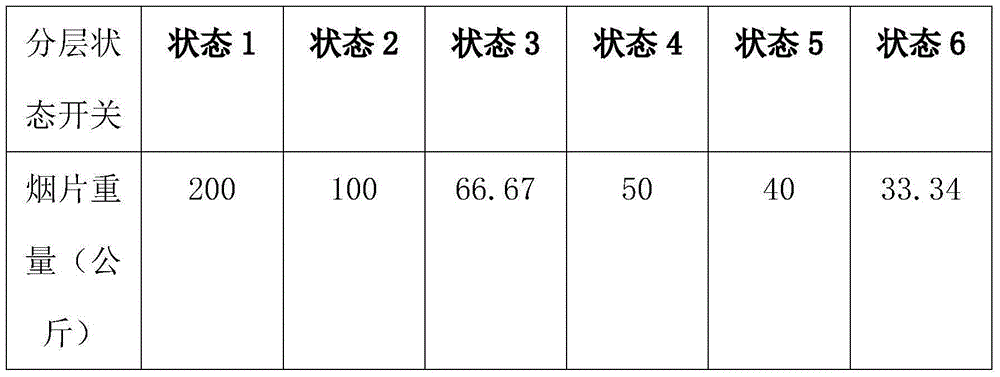

[0022] In the pre-pressing and packaging process, when the layered state selection switch 8 is operated to select the fourth layer, the cigarette sheet is sent to the electronic belt scale 2 through the feeding conveyor belt 1, and the running speed of the electronic belt scale 2 is automatically controlled by PLC. The finished smoke sheet falls into the finished smoke box 4 through the material box 3. When the electronic belt scale 2 reaches the preset layered weight of 50 kg, the feeding conveyor belt 1 and the electronic belt scale 2 stop feeding, and the smoke sheet pre-pressing mechanism mainly presses When the head 5 is pressed down, the main pressure head reset switch 53 is activated, and the main pressure head reset switch 53 is in an open circuit state. The depression depth of the main pressure head 5 is controlled by the PLC through time, and the required compression height of 50 kg of material can be obt...

Embodiment 2

[0023] Embodiment 2: the fifth layer of smoke sheet pressing

[0024] In the pre-pressing and packaging process, when the layered state selection switch 8 is operated to select the fifth layer, the smoke sheet is sent to the electronic belt scale 2 through the feeding conveyor belt 1, and the running speed and time of the 2 are automatically controlled by the PLC. The smoke sheet falls into the finished cigarette box 4 through the material box 3. When the electronic belt scale 2 reaches the pre-examination layered weight of 40 kg, the feeding conveyor belt 1 and the electronic belt scale 2 stop feeding, and the main pressure head 5 smoke sheet pre-pressing mechanism The main pressure head 5 is pressed down, the main pressure head reset switch 53 is activated, the main pressure head reset switch 53 is in an open state, the depression depth of the main pressure head is controlled by PLC through time, and the required compression height of 40 kg of material can be obtained Size s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com