Device for feeding chain rivets into tray automatically

An automatic, pallet technology, applied in the field of mechanical engineering, can solve the problems of low efficiency, time-consuming and labor-intensive, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to further illustrate the technical solutions of the present invention, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

[0072] Such as Figure 1 to Figure 15 shown.

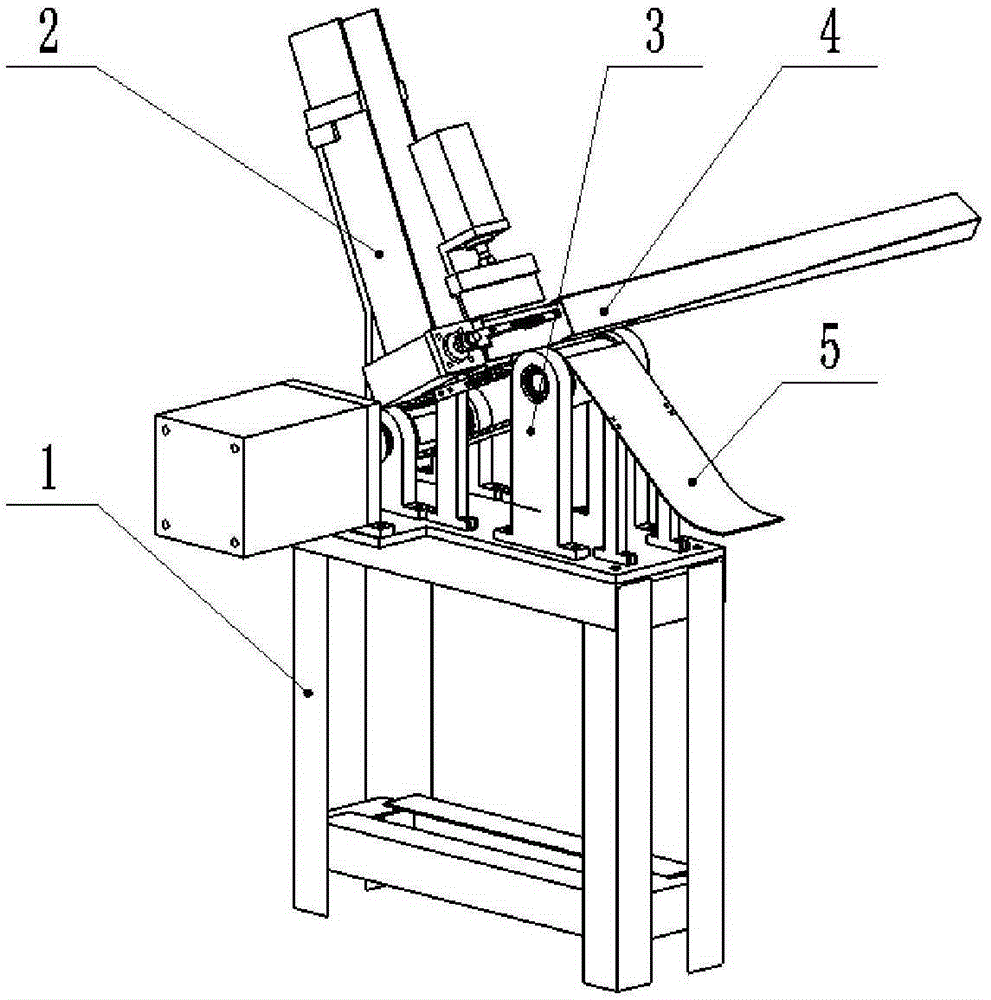

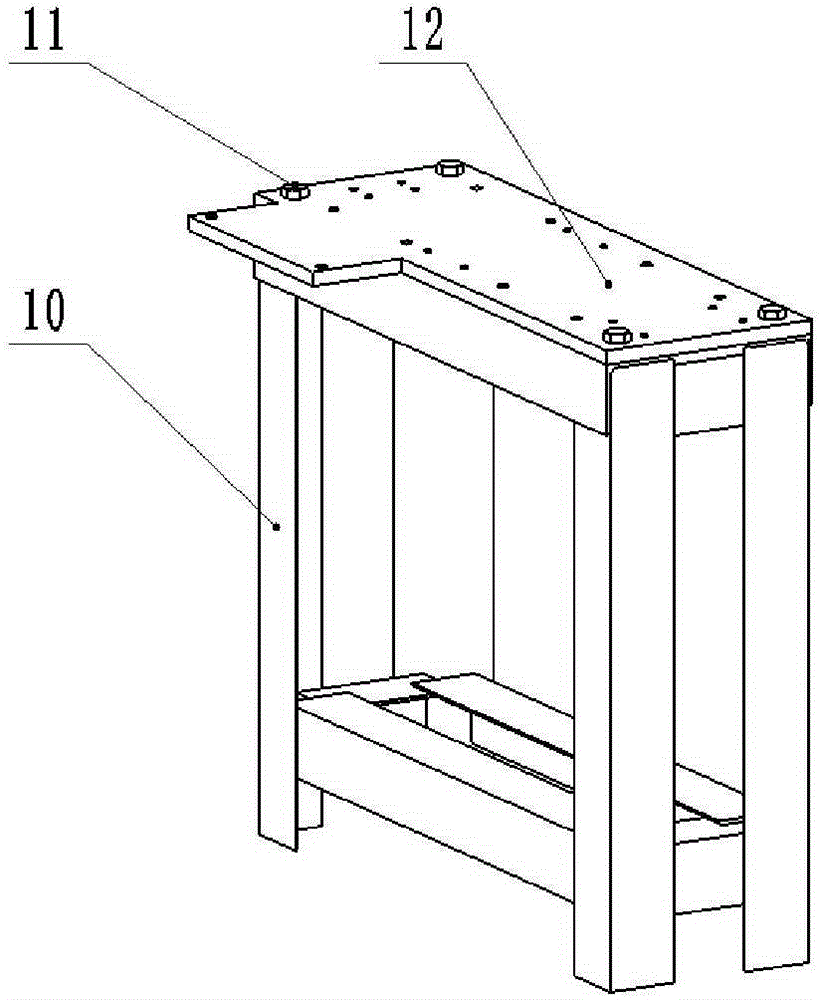

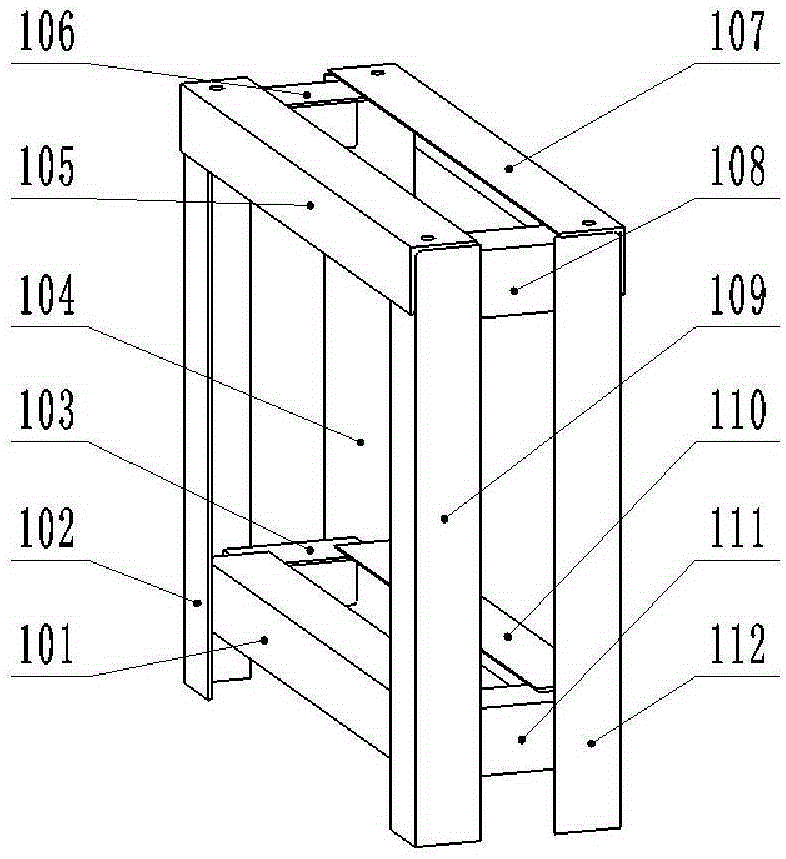

[0073] The present invention is a device for automatically inserting nails, comprising a frame 1, a tray hopper mechanism 2, a tray conveying mechanism 3, a nail row inserting mechanism 4, and a tray slideway mechanism 5, and the frame 1 is used for installing and positioning each component platform, the pallet bin mechanism 2 and the pallet conveying mechanism 3 are combined to realize the automatic conveying and moving of the pallet, the nail arranging mechanism 4 realizes the automatic conveying, flipping, clamping and palletizing of the arranging nails, and the pallet slideway mechanism 5 is used for Realize the automatic sliding of pallets into other stations.

[0074] Described frame 1 is cuboid platform structure, is positioned at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com