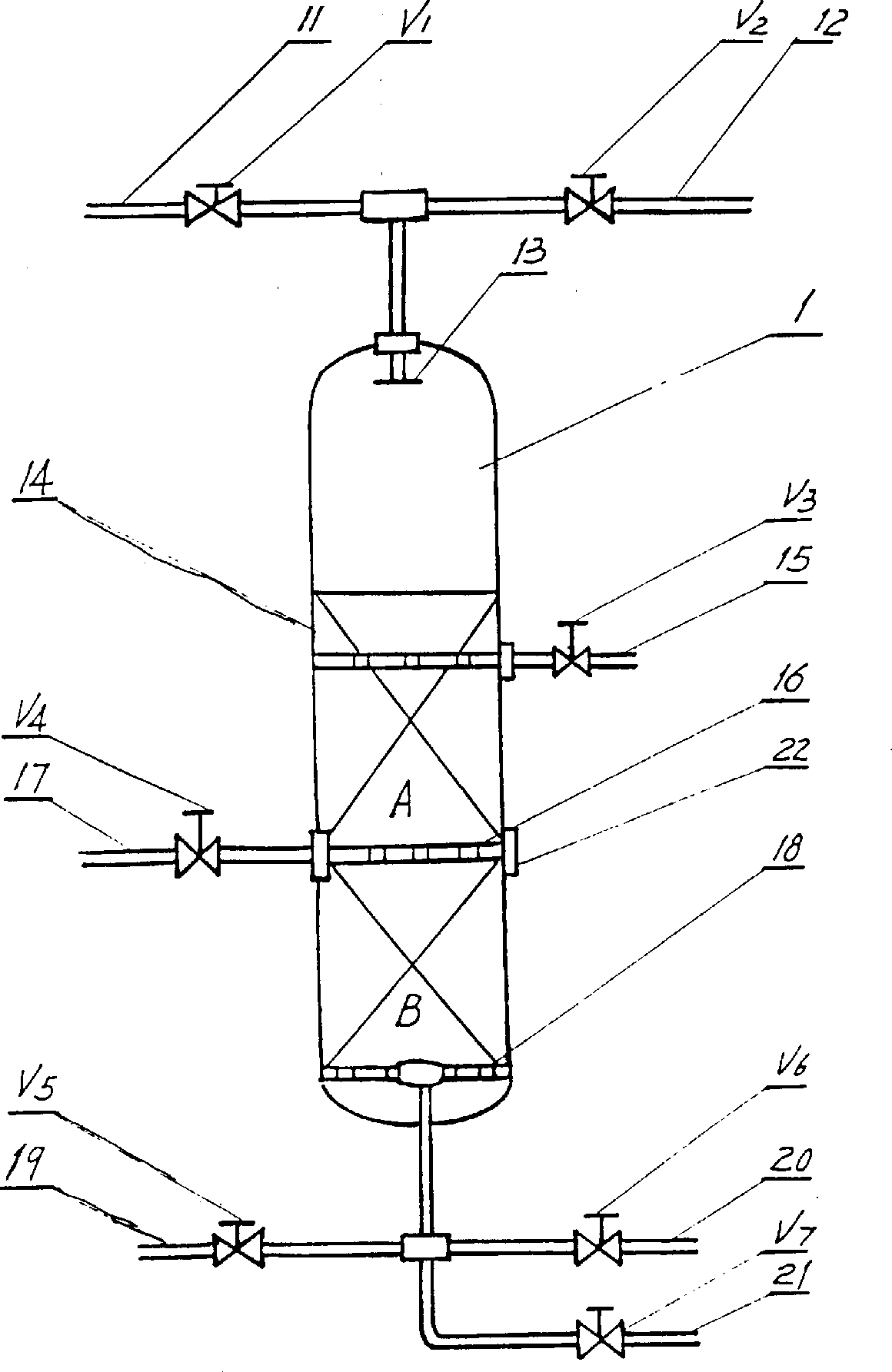

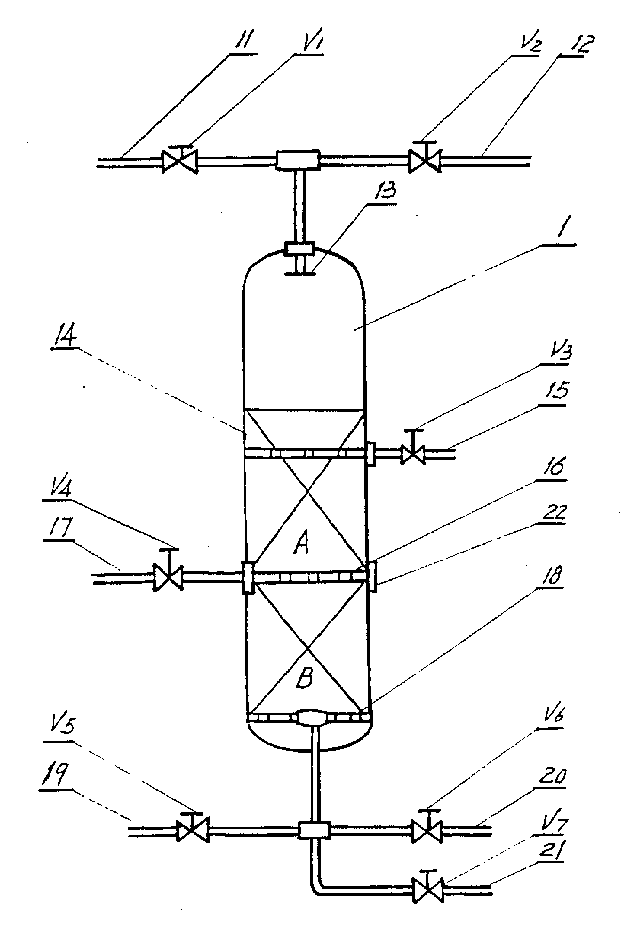

Fixed double-layer-bed ion exchange resin regenerating method and apparatus thereof

A technology of ion exchange resin and double bed, which is applied in the direction of ion exchange regeneration, ion exchange, ion exchange water/sewage treatment, etc. It can solve the problems of reducing equipment space utilization, unfavorable automatic control, and poor water quality. Achieve the effects of improving the quality of product water, facilitating program control and automation, and reducing the expansion space of backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] A double-bed anion exchange column with a diameter of 2 meters, a column height of 3 meters, and a total resin height of 2 meters, of which the height of 201×7-SF strong base anion resin is 0.9 meters, and the height of D301-SC weak base anion resin is 1.1 meters.

[0041] According to the same method as in Example 1, using industrial caustic soda as a regeneration agent, the 0.4m 3 Industrial caustic soda is made into a solution with a concentration of 0.9% as a pre-regeneration liquid, and the double-bed resin is backwashed and stratified-pre-regeneration with a flow rate of 5.5m / h from bottom to top; after the pre-regeneration liquid is passed into , let stand for 25 minutes; then add 0.3m 3 Industrial caustic soda is made into a solution with a concentration of 2.0% as the regeneration solution, and the double-layer bed is regenerated at a flow rate of 3m / h; after the regeneration solution is passed through, continue to replace and rinse with water for 30 minutes; t...

Embodiment 3

[0043] A double-bed cation exchange column with a diameter of 2.2 meters, a column height of 4 meters, and a total resin loading height of 2.6 meters, of which 001×7-SF is 1.2 meters high and D113-SC is 1.4 meters high. The lower row is installed at the resin interface 0.2 meters above.

[0044] According to the same method as in Example 1, using industrial hydrochloric acid as a regeneration agent, the 1.3m 3 Industrial hydrochloric acid is made into a solution with a concentration of 1.0% as the pre-regeneration solution, and the resin is backwashed and stratified at a flow rate of 7.5m / h-pre-regeneration: After the pre-regeneration solution is passed through, let it stand for 25 minutes; then 1.2m 3 Industrial hydrochloric acid is made into a solution with a concentration of 2%, and the resin is regenerated at a flow rate of 4m / h; after the regenerated solution is introduced, it is replaced and rinsed with water for 40 minutes; followed by positive washing, the positive was...

Embodiment 4

[0045] The water source is river water, a double-layer anion exchange column with a diameter of 2.5 meters and a column section height of 4 meters. The height is 1.58 meters, and the lower row is at the resin interface.

[0046] According to the same method as in Example 1, using industrial caustic soda as a regeneration agent, the 0.6m 3 The industrial caustic soda is formulated into a pre-regeneration solution with a concentration of 0.9%, and the resin is pre-regenerated and backwashed and stratified at a flow rate of 5m / h: after the pre-regeneration solution is passed through, it is allowed to stand for 15 minutes; then the 0.5m 3 Industrial caustic soda is made into a solution with a concentration of 2.0% as the regeneration solution, and the resin is regenerated at a flow rate of 3.5m / h; then the water is replaced and rinsed for 25 minutes; finally, the positive wash is performed, and the parameters are: small positive wash flow rate 10m / h , time 5 minutes; medium posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com