Two-sided ink-jet printer

An inkjet printing machine and front printing technology, which is applied to printing, typewriters, etc., can solve the problems of large space occupation, inaccurate printing, and high flatness requirements, and achieve the goal of improving printing accuracy, preventing printing errors, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

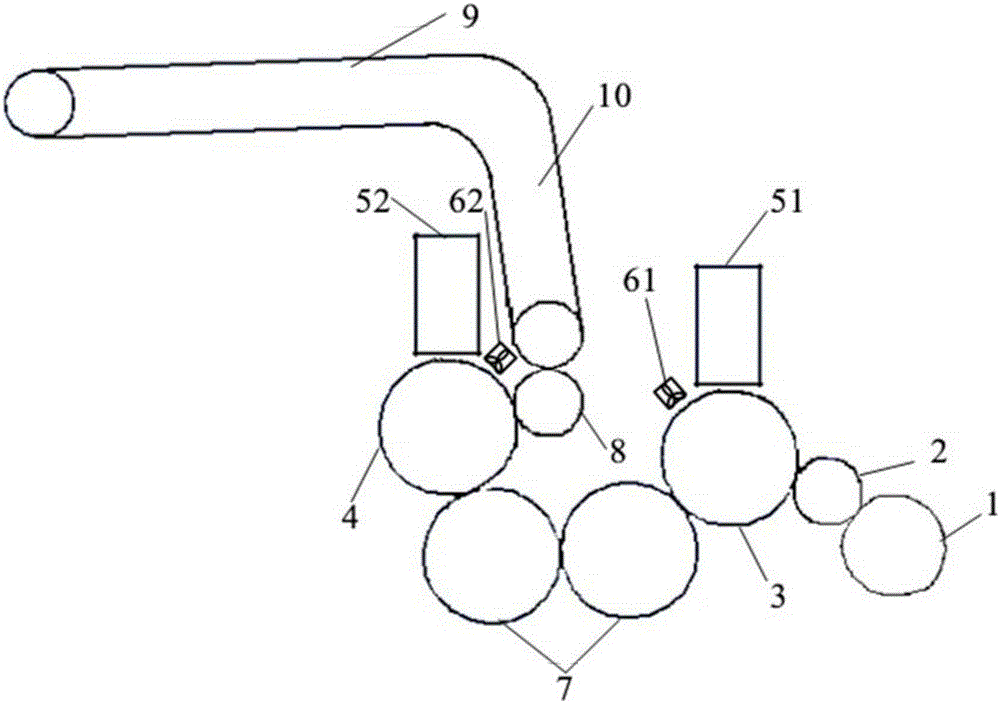

[0026] see figure 1 , the present invention provides a double-sided inkjet printing machine, including a paper supply unit, a printing unit, and a delivery unit; The printing unit prints; the printing unit includes a front printing cylinder 3, a paper transfer unit, a back printing cylinder 4, discontinuous inkjet heads 51, 52 and drying devices 61, 62, and the back printing cylinder 4 is located at the Obliquely above the front printing cylinder 3, the inkjet head I51 is arranged directly above the front printing cylinder 3, and the drying device I61 is arranged on one side of the inkjet head I51, and the drying device I61 Located on the side of the inkjet head I51 away from the paper supply unit, the inkjet head II52 is arranged directly above the back printing cylinder 4, and the drying machine is arranged on one side of the inkjet head II52. Device II62; the paper transfer unit includes 2 paper transfer cylinders 7, the paper transfer cylinder 7 is located below the front...

Embodiment 2

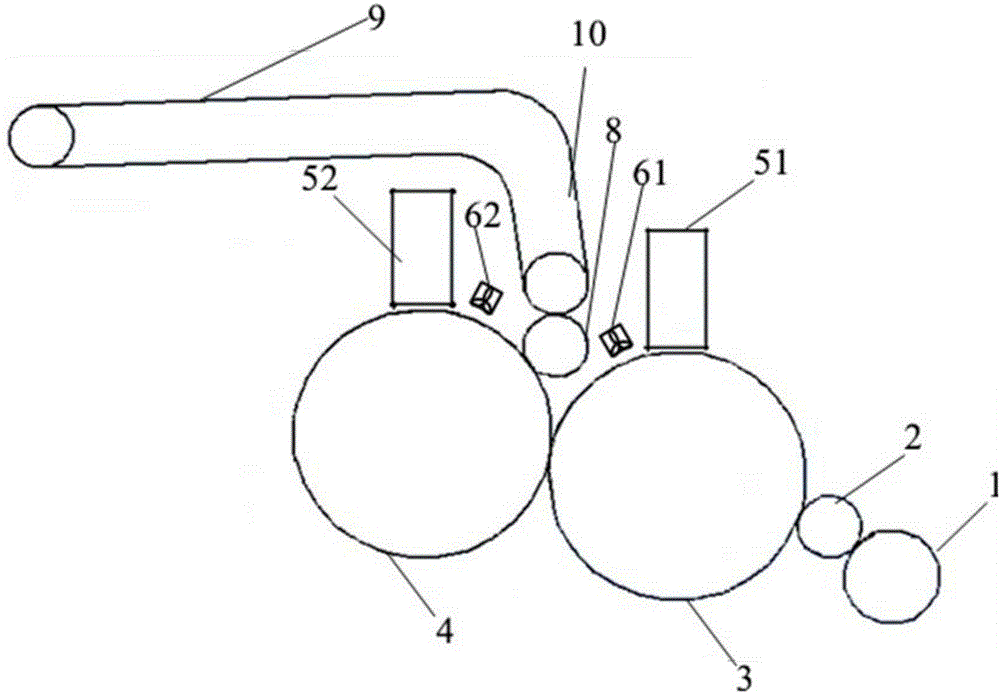

[0029] see figure 2 , the present invention provides a double-sided inkjet printing machine, including a paper supply unit, a printing unit, and a delivery unit; The printing unit prints; the printing unit includes a front printing cylinder 3, a back printing cylinder 4, discontinuous inkjet heads 51, 52 and drying devices 61, 62, and the back printing cylinder 4 is located at the front printing cylinder 3 Obliquely above the front printing cylinder 3, the inkjet head I51 is provided, and one side of the inkjet head I51 is provided with the drying device I61. The ink head I51 is far away from the side of the paper supply unit, the inkjet head II52 is arranged directly above the back printing cylinder 4, and the drying device II62 is arranged on one side of the inkjet head II52; The front printing cylinder 3 transmits the paper printed on the front to the back printing cylinder 4 for reverse printing; the paper delivery unit includes a paper delivery cylinder 8, a paper deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com