Antibacterial, waterproof and moisture-permeable composite fabric and preparation method thereof

A composite fabric, waterproof and moisture-permeable technology, applied in protective equipment, chemical instruments and methods, protective clothing, etc., can solve the problems of increasing the burden on medical workers, difficult to ensure the efficiency of protection, reducing flexibility and comfort, etc. To achieve the effect of light material, prevent bacteria and macromolecular viruses from entering, and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

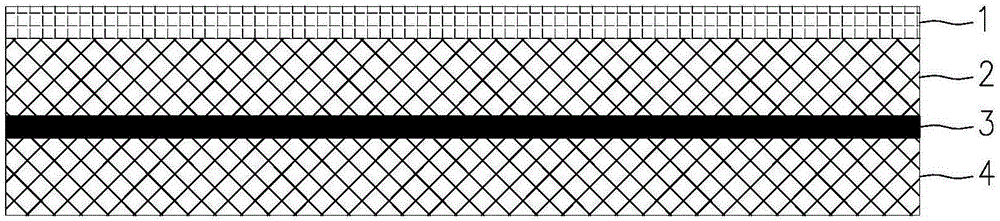

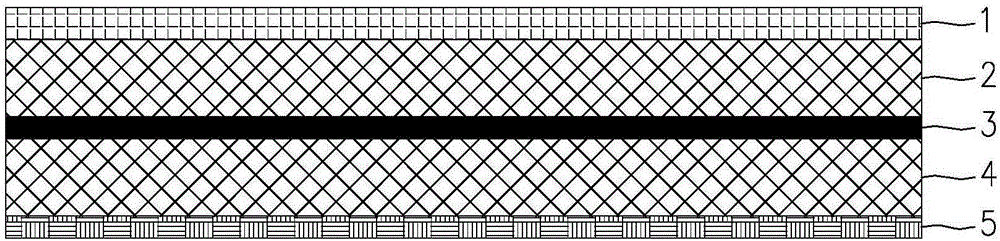

[0046] The following is a detailed description of the preparation process of the antibacterial waterproof and moisture-permeable composite fabric. It should be pointed out that this preparation process only involves the outer polypropylene non-woven fabric 2, the polyether thermoplastic polyurethane film 3 and the inner polypropylene non-woven fabric 4 Illustration of the preparation of the three-layer structure.

[0047] The operating methods described in the following instructions are conventional methods unless otherwise specified; the reagents in the methods can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0049] 1.1 Preparation of silver-loaded rectorite

[0050] 1) The rectorite is first modified by sodium treatment

[0051] Fully disperse the natural rectorite in distilled water, and add the mixed sodium carbonate and sodium polyphosphate into the hydrated natural rectorite slurry under constant stirring, wherein the sodium carbonate and sodium polyphosphate The molar ratio is 1:1, the total mass of sodium carbonate and sodium polyphosphate added is 6% of the mass of rectorite, stirred evenly and fully tumbled, taken out and aged for 24 hours to obtain sodium rectorite slurry; Then, under the conditions of 70°C and pH value of 7.37, the obtained sodium rectorite slurry was modified by cetyl trimethyl ammonium bromide, and the addition of cetyl trimethyl ammonium bromide The mass is 8% of the mass of the rectorite, and the reaction time is 2 hours, and the rectorite after sodium modification treatment can be obtained.

[0052] 2) taking rectorite, which is a sodium-based rec...

Embodiment 2

[0060] 2.1 Preparation of silver-loaded rectorite

[0061] 1) The rectorite is first modified by sodium treatment

[0062] Fully disperse the natural rectorite in distilled water, and add the mixed sodium carbonate and sodium polyphosphate into the hydrated natural rectorite slurry under constant stirring, wherein the sodium carbonate and sodium polyphosphate The molar ratio is 1:1, the total mass of sodium carbonate and sodium polyphosphate added is 7% of the mass of rectorite, stirred evenly and fully tumbled, taken out, sealed and aged for 24 hours, to obtain sodium rectorite slurry; Then, under the conditions of 70°C and pH value of 7.37, the obtained sodium rectorite slurry was modified by cetyl trimethyl ammonium bromide, and the addition of cetyl trimethyl ammonium bromide The mass is 9% of the mass of the rectorite, and the reaction time is 2.5 hours, and the rectorite after sodium modification treatment can be obtained.

[0063] 2) taking rectorite, which is a sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com