A kind of steam curing method and device

A steam curing and time-long technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as affecting production efficiency, cracking of components, and failure of the strength of concrete components to reach the maximum expected value, achieving automatic control and improving compression resistance. Intensity, the effect of shortening the steaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

[0040] First, an example of a steaming method provided by the present invention is introduced.

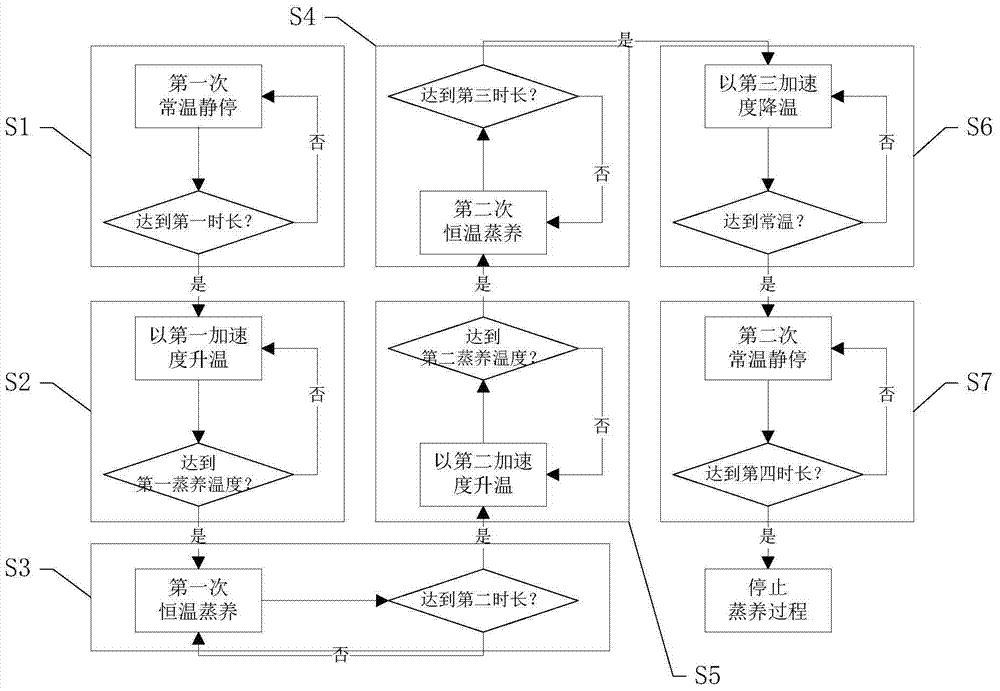

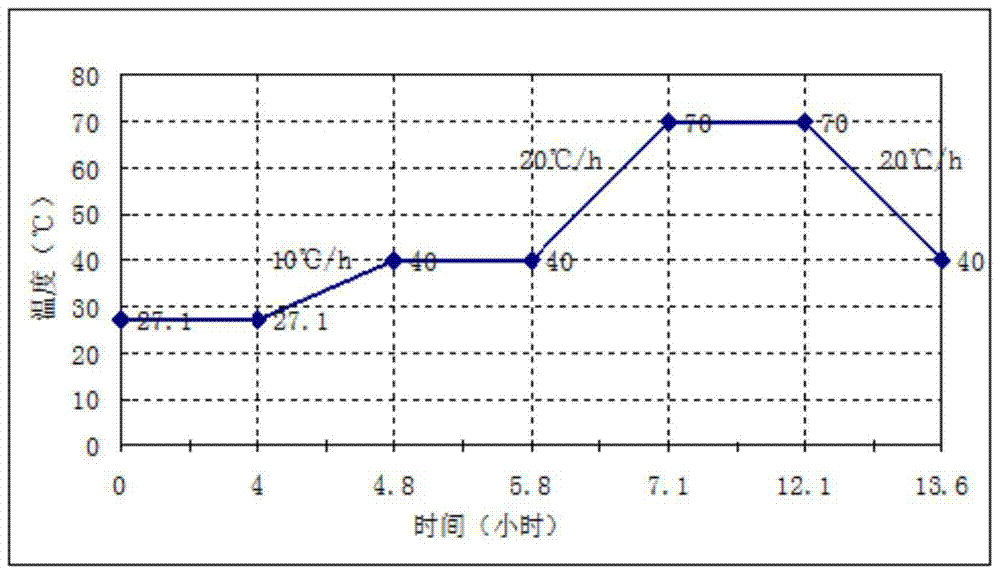

[0041] figure 1 This is a schematic flow diagram of an embodiment of the steam-cooking method provided by the present invention. As shown in the figure, the steaming method in this embodiment includes the following steps:

[0042] S1: After the concrete component is poured and formed, it is placed in the steam curing hood, and it is statically stopped for the first time at room temperature;

[0043] S2, increasing the air temperature in the steaming hood at the first speed at a uniform speed until the air temperature in the steaming hood reaches the first steaming temperature;

[0044] S3, maintaining the air temperature in the steam curing hood at the first steam c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com