Multilayer and multipass welding track planning method for variable-groove-width heavy and medium plates

A groove width, multi-layer and multi-channel technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding quality, incomplete penetration, variable groove, etc., and achieve great research value and feasibility, good welding quality, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

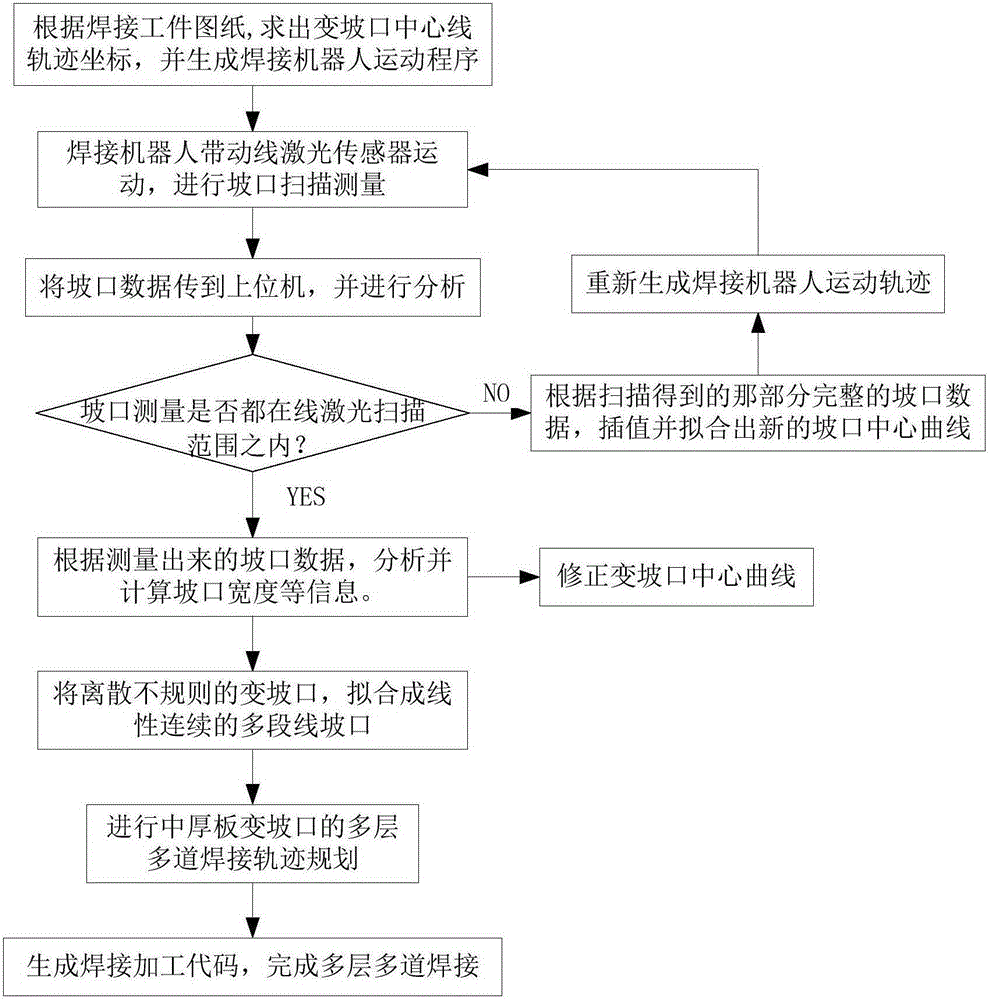

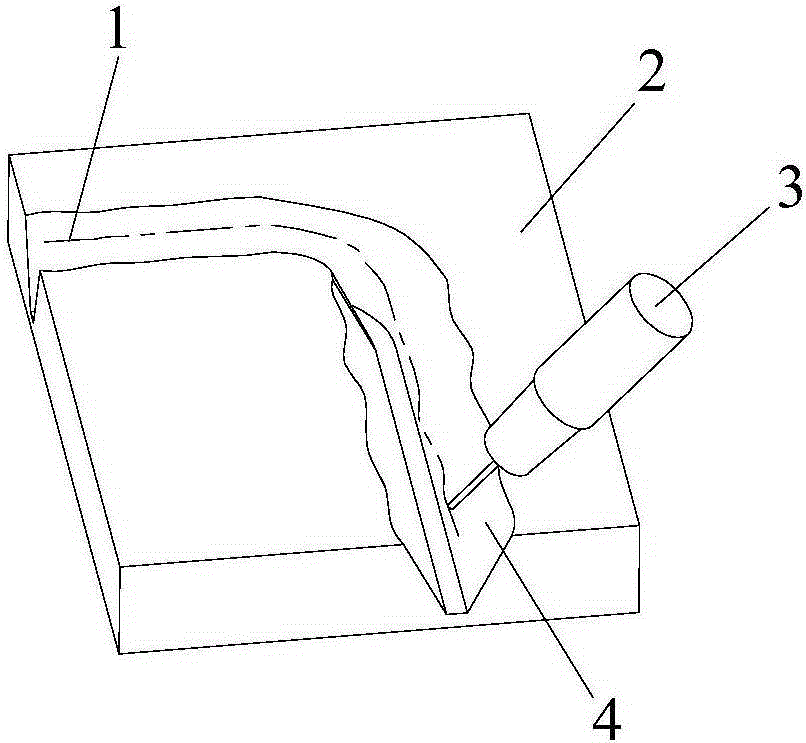

[0036] What the present invention discloses is a method for planning the multi-layer and multi-pass welding trajectory of medium-thick plate with variable groove width, such as Figure 2 to Figure 8 As shown, it is a preferred embodiment of the present invention. In this embodiment, a variable-groove welding workpiece with equal thickness (that is, the groove thickness of the workpiece is constant) and a flat plate (that is, the workpiece is a flat workpiece) is taken as an example. Of course, the following methods are also applicable to other forms of variable groove welding workpieces.

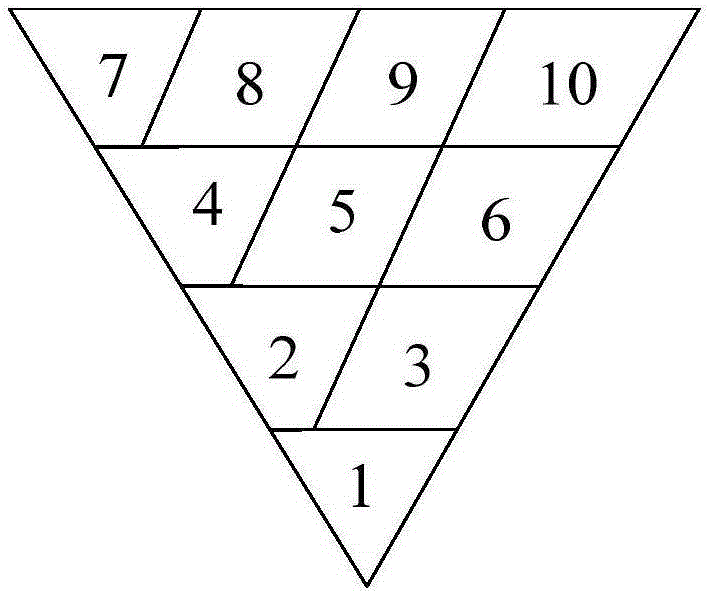

[0037] Welding workpieces of medium and thick plates generally adopt multi-layer and multi-pass welding methods, and the specific number of welding layers and passes are designed according to actual needs. figure 1 The V-groove workpiece shown uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com