Sizing machine

A technology for sizing mills and racks, which is applied in the direction of metal rolling racks, metal rolling mill stands, metal rolling, etc., can solve the problems of large volume and weight of roll stands, long process time, and increased costs, and achieve Reduced workload, reduced production costs, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

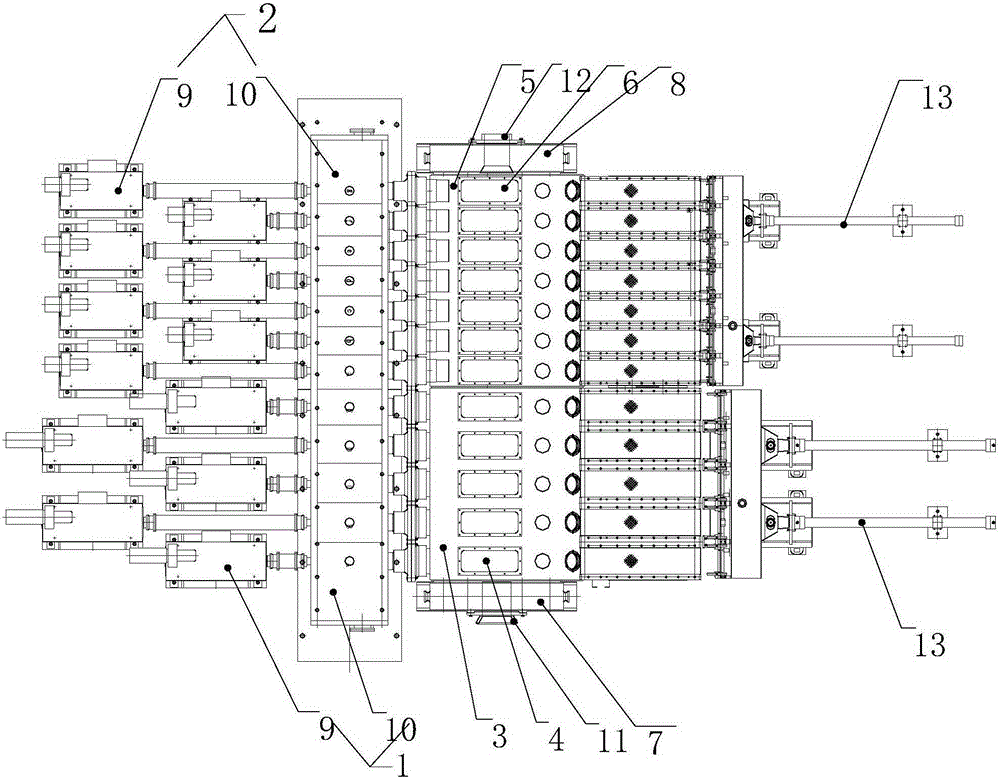

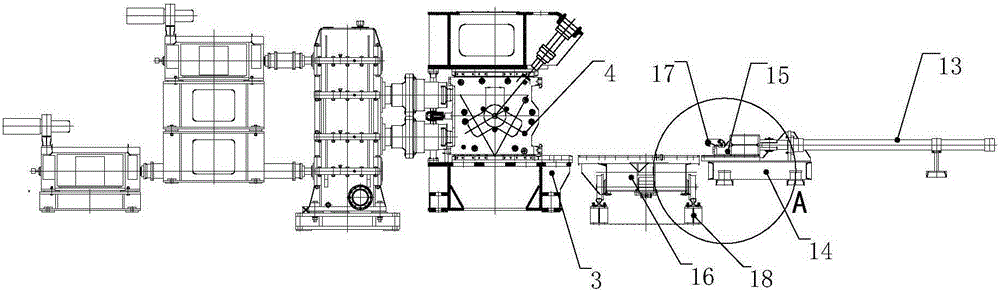

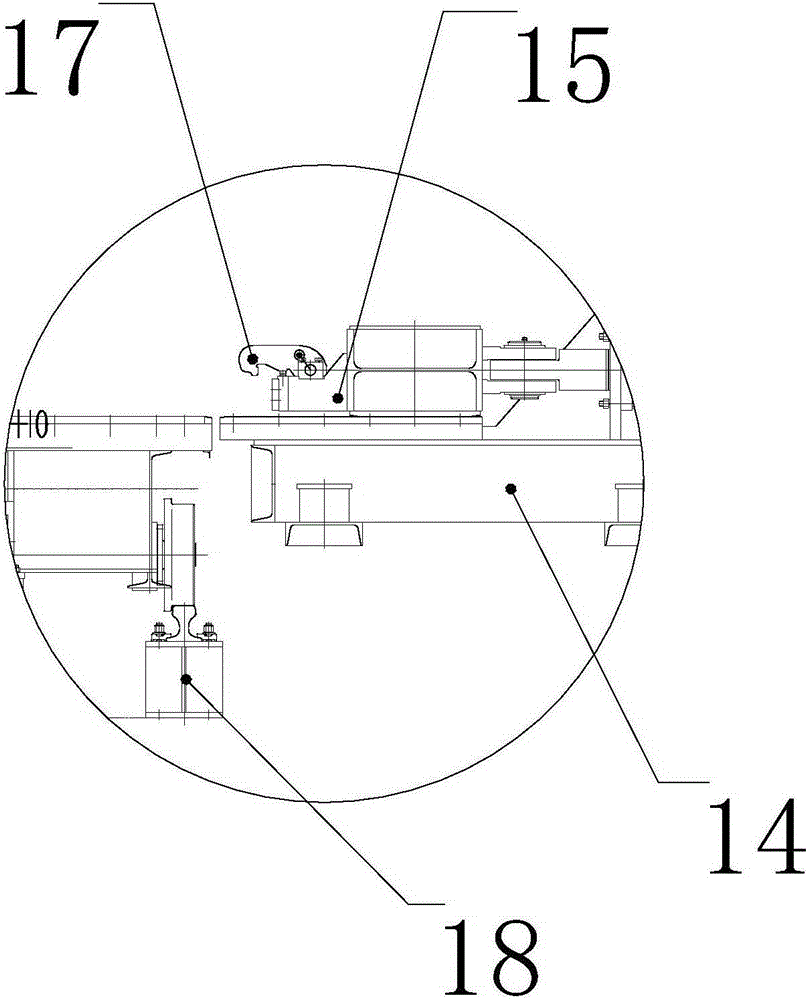

[0019] see Figure 1 to Figure 3 , a sizing machine according to a preferred embodiment of the present invention includes a first transmission device 1, a second transmission device 2, a first stand 3, a first roll stand 4, a second stand 5 and a second roll Stand 6, the first roll stand and the second roll stand are arranged in sequence along the rolling direction of the steel pipe, and the first roll stand is fixedly arranged on the first stand, and the second roll stand is fixedly arranged on the second stand On the seat, the outer diameter of the largest blank tube that can be rolled in the first roll stand is greater than the outer diameter of the largest blank tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com