Dedusting tower for waste gas treatment

A waste gas treatment and dedusting tower technology, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of workshop shutdown, prolonging the service life of electric field, and broken discharge electrodes, etc., so as to prolong the service life, prolong the blocking time, The effect of large discharge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

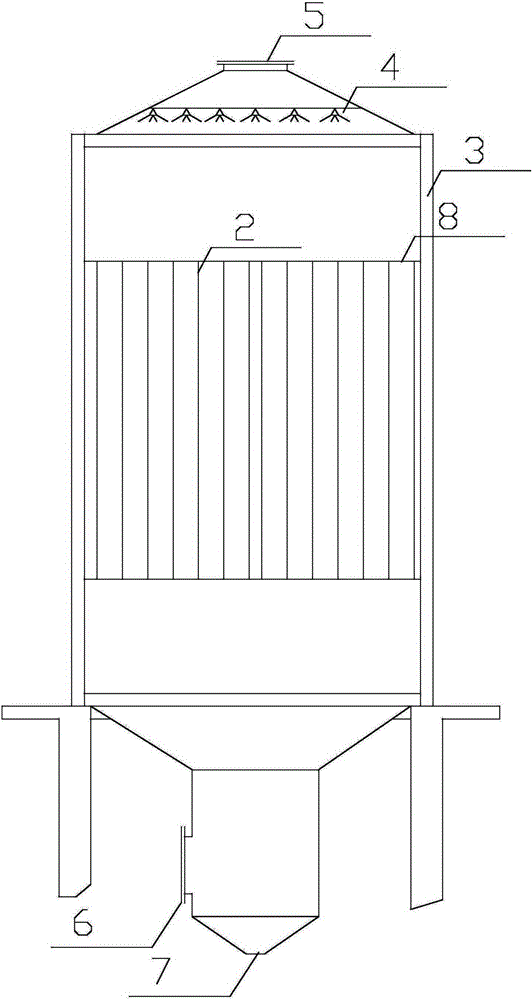

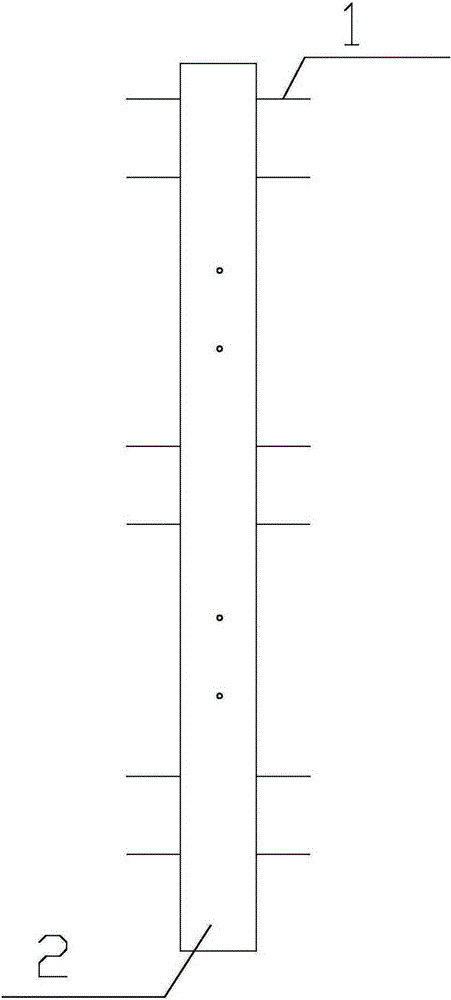

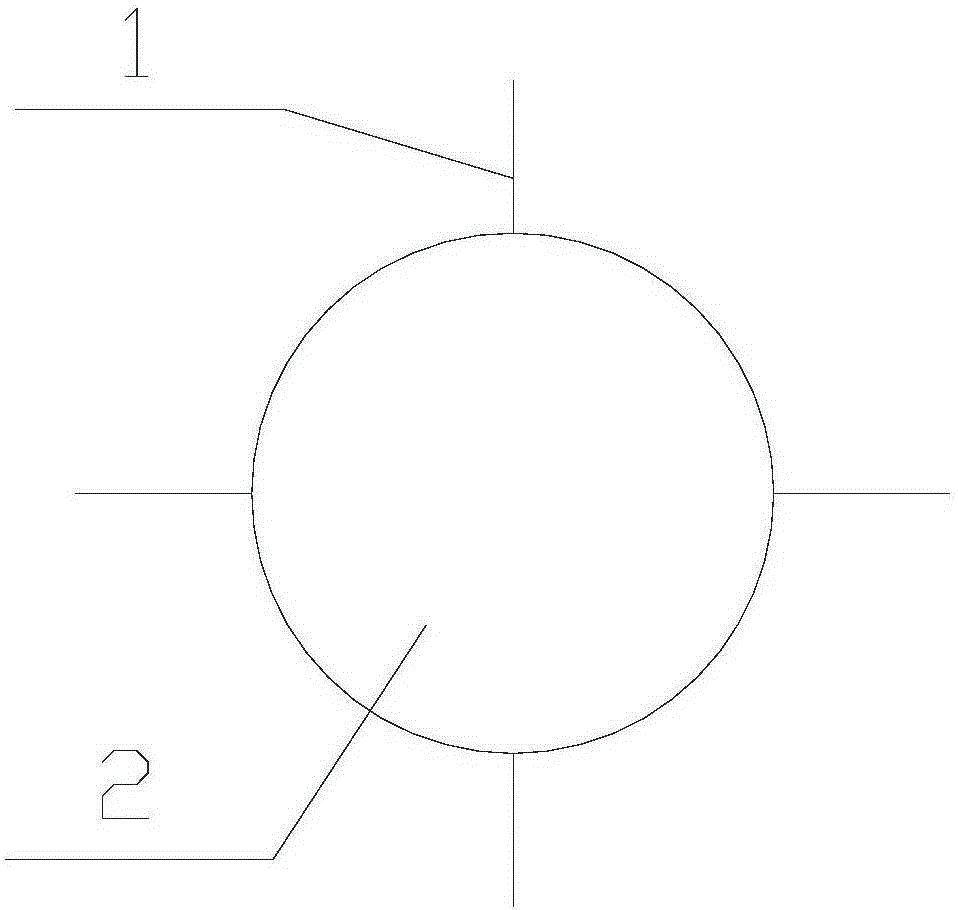

[0021] see figure 1 , The exhaust gas treatment dust removal tower of this embodiment includes a tower body 3, a discharge electrode, a conductive plate 8, a spray system 4, a sewage channel, a honeycomb anode, a cathode electrode wire, and the like. The discharge electrode, the conductive plate 8, and the spray system 4 are all installed in the tower body 3. An air inlet 5 is provided on the top of the tower body 3, and a spray system 4 is arranged below the air inlet 5. The spray system 4 is located in the discharge chamber. above the electrodes. The tower bottom of the tower body 3 is provided with a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com