Tobacco leaf segmented strip roasting method

A curing method and a technology for dividing slices, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as the lack of organic combination of sliced tobacco, achieve the effects of reducing energy consumption, increasing the effective amount of smoke loaded, and simplifying the processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

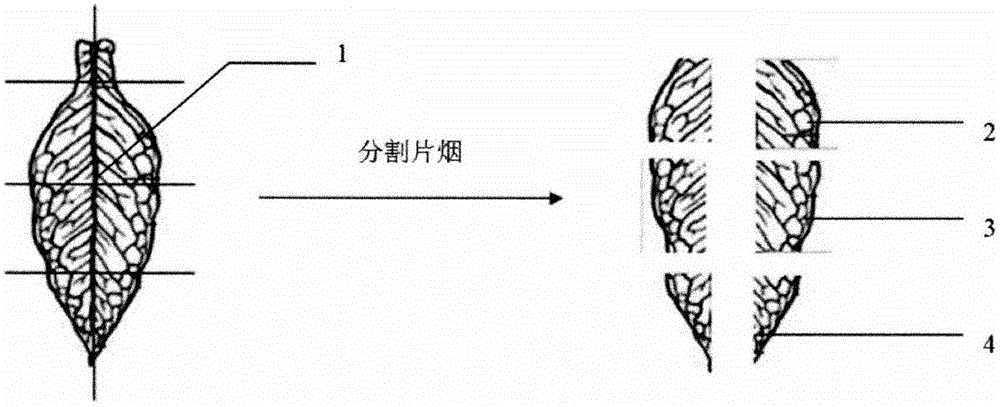

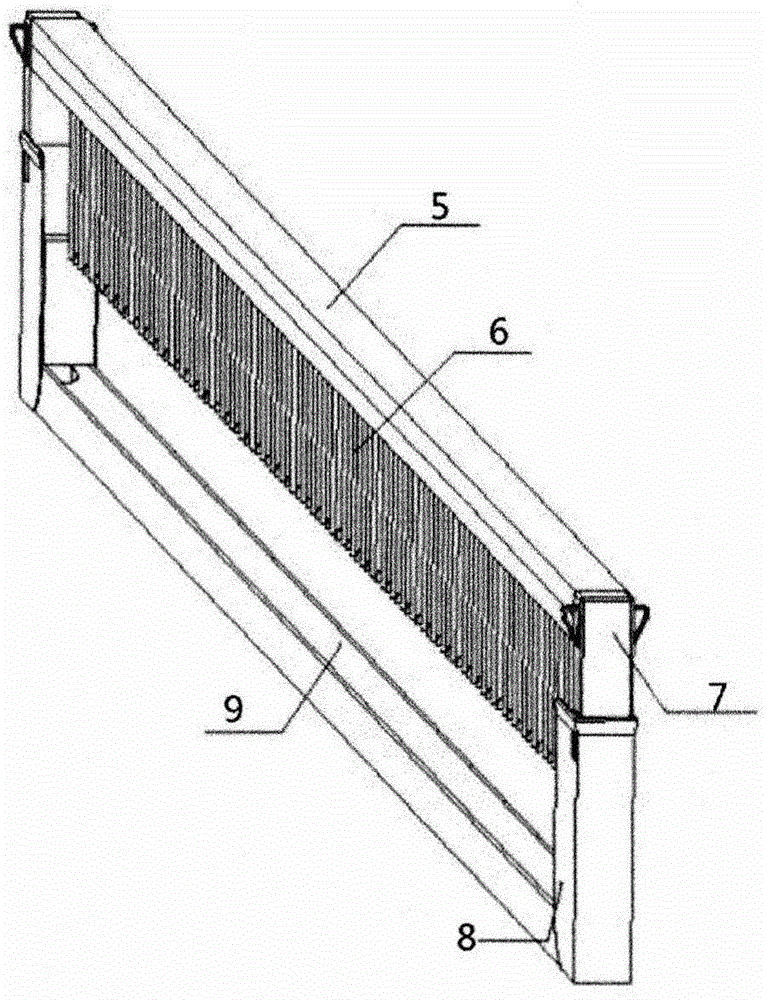

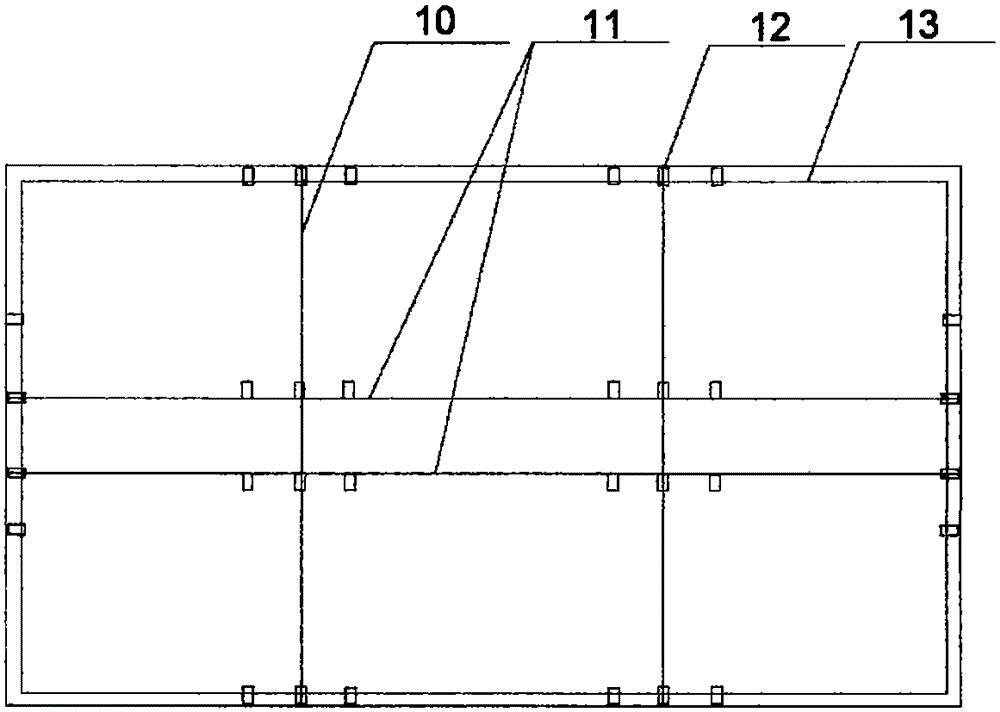

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as Figure 1-4 as shown, figure 1 It is a schematic diagram of the tobacco cutting process of the present invention. figure 2 It is a structural schematic diagram of the clamping device of the present invention. image 3 It is a schematic diagram of the top view direction of the tobacco laminar equipment of the present invention. Figure 4 It is the sheet tobacco baking process chart of the present invention.

[0031] The present invention relates to a method for roasting cut tobacco leaves and sliced tobacco, which includes a finishing step and a roasting step, wherein:

[0032] Tobacco finishing steps are:

[0033] A. Steps for laminar tobacco: according to the mature and yellowing of the tobacco leaves of the tobacco plant, the mature and harvested complete tobacco leaves are divided according to the position and the main vein 1 is removed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com