Crawler-type intelligent drive corn harvester

A corn harvester, intelligent driving technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of poor passability of climbing and crossing ridges, difficult to exert operation performance, and long time to clear the road, so as to eliminate the phenomenon of blockage. , The degree of automation control is easy to achieve, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

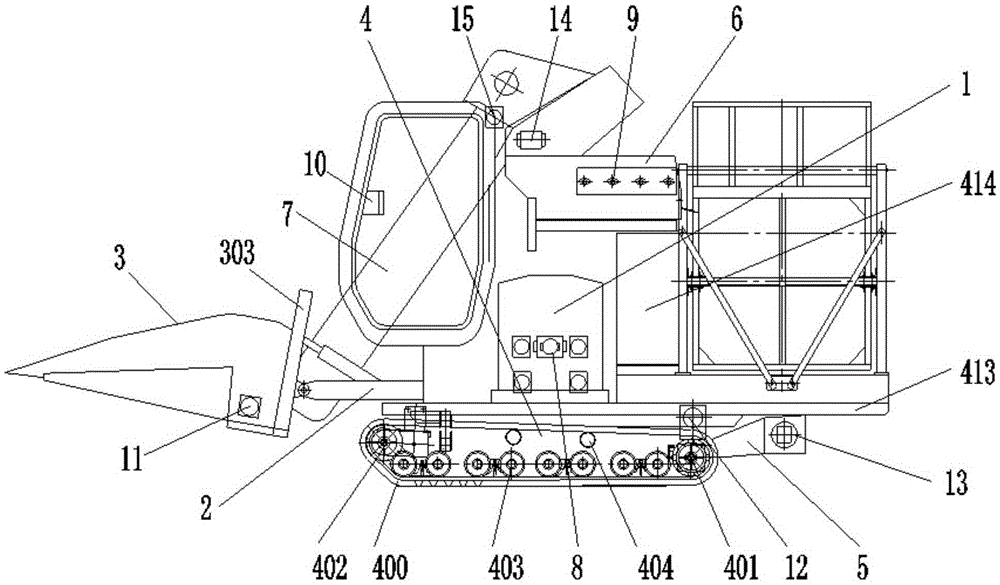

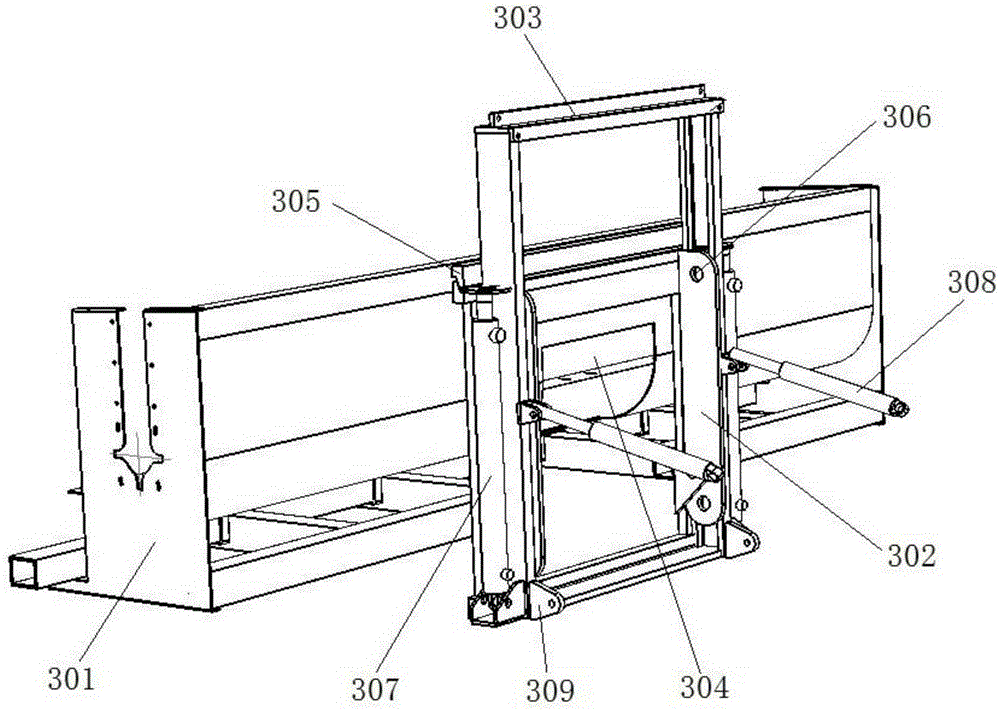

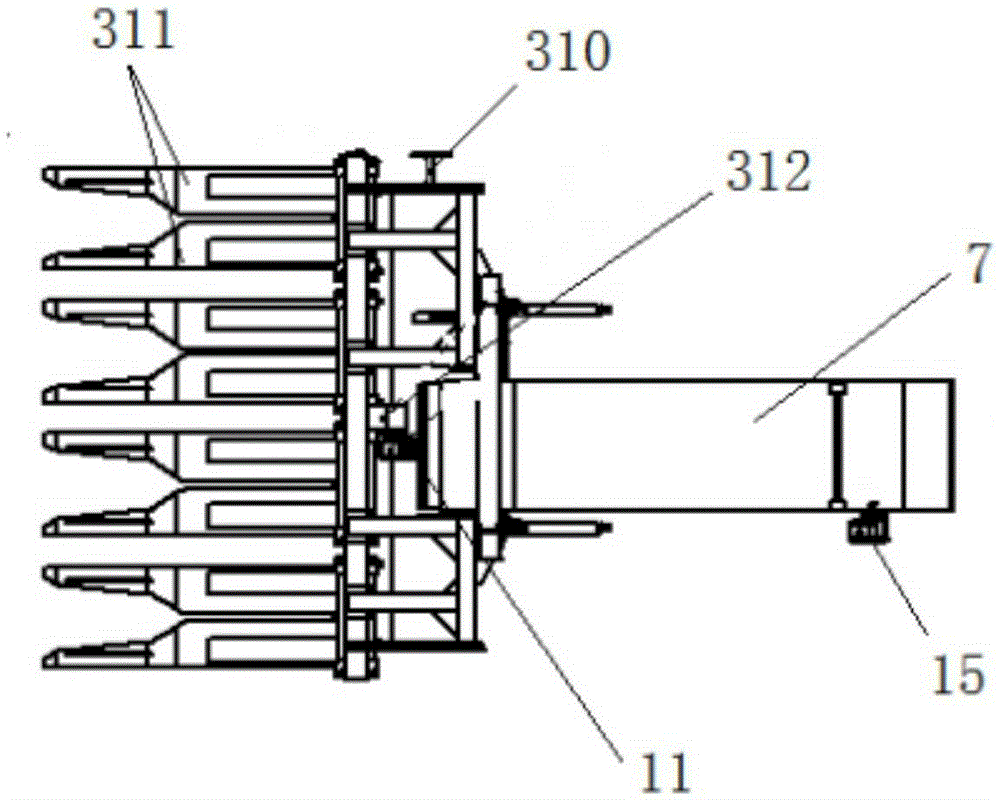

[0050] The crawler type intelligent driving corn harvester of the present invention, such as figure 1 As shown, it includes a walking device 4, a header 3, an elevator 7, a peeling device 6 and a crushing device 5, and the crawler-type intelligent driving corn harvester also includes a powertrain and a control system;

[0051] The power assembly includes an engine 1, a hydraulic pump 8, an electro-hydraulic control valve 9 and a hydraulic motor, the engine 1 is connected to the transfer case, and each output shaft of the transfer case is connected to the above-mentioned traveling device 4, the header 3, and the lift respectively. 7, the peeling device 6 and the hydraulic pump 8 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com