Small-sized self-propelled garlic combine harvester

A combine harvester and self-propelled technology, which is applied to digging harvesters, harvesters, topping machines, etc., can solve the problems of difficult access to scattered plots, large harvest losses, and high prices, so as to ensure operation time, The effect of reasonable power distribution and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the following is only exemplary and does not limit the protection scope of the present invention.

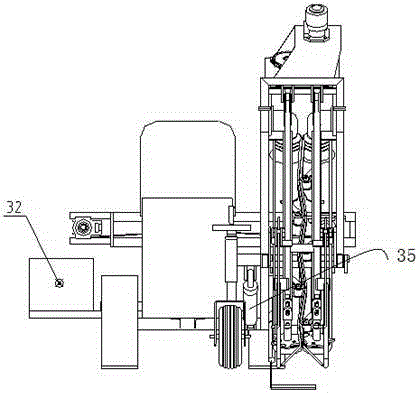

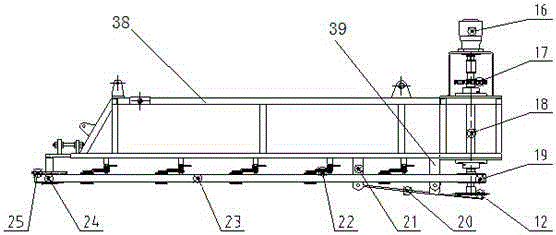

[0035] Reference attached figure 1 and figure 2 , a small self-propelled garlic combine harvester, comprising: a self-propelled chassis 6, a hoist 1, an excavating device, a clamping and conveying device 5, a stem cutting device 12, a garlic conveying device 11, a garlic collecting box 32 and a hydraulic system The self-propelled chassis 6 includes a frame 4, an engine 8, a gearbox 9 and a lifting support 7; the engine 8 is installed in the middle part of the self-propelled chassis 6, and a seat 14 is arranged above the engine 8; The input end of the box 9 is connected to the output end of the engine 8, and the output end of the gearbox 9 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com