Digitalized transformation method for transformer substation

A substation, digital signal technology, applied in electrical components, circuit devices, information technology support systems, etc., can solve the problems of reduced work efficiency, complex construction process, large operation interval workload, etc., to achieve high transformation efficiency and small limitations. , the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. The present invention will be further described in detail below with reference to the drawings and specific embodiments.

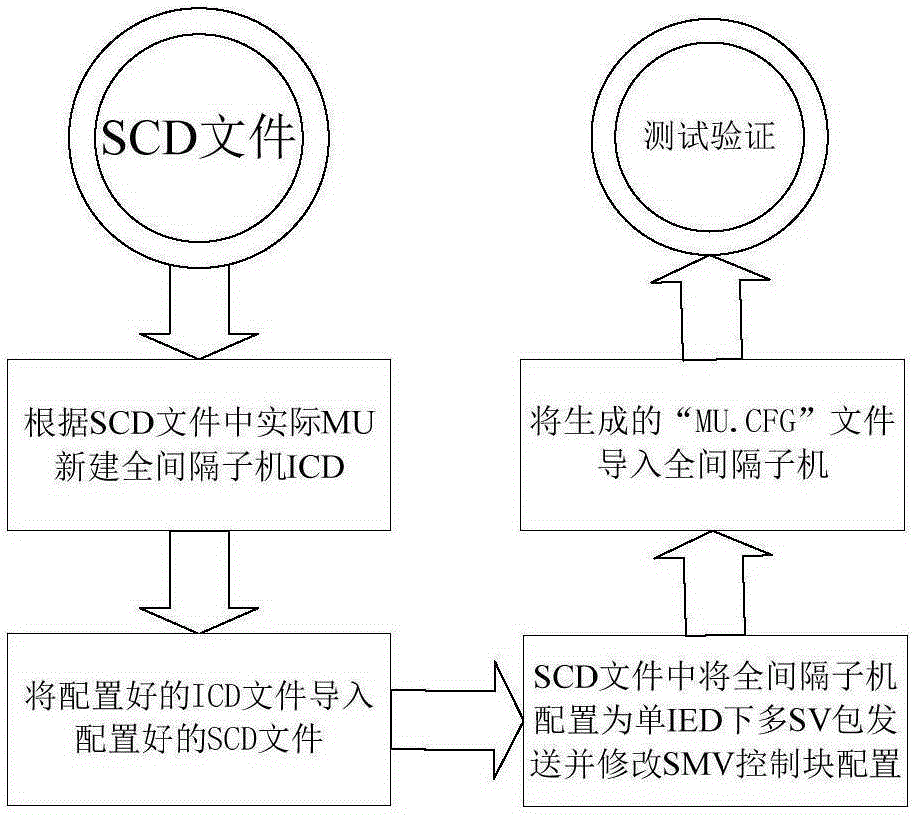

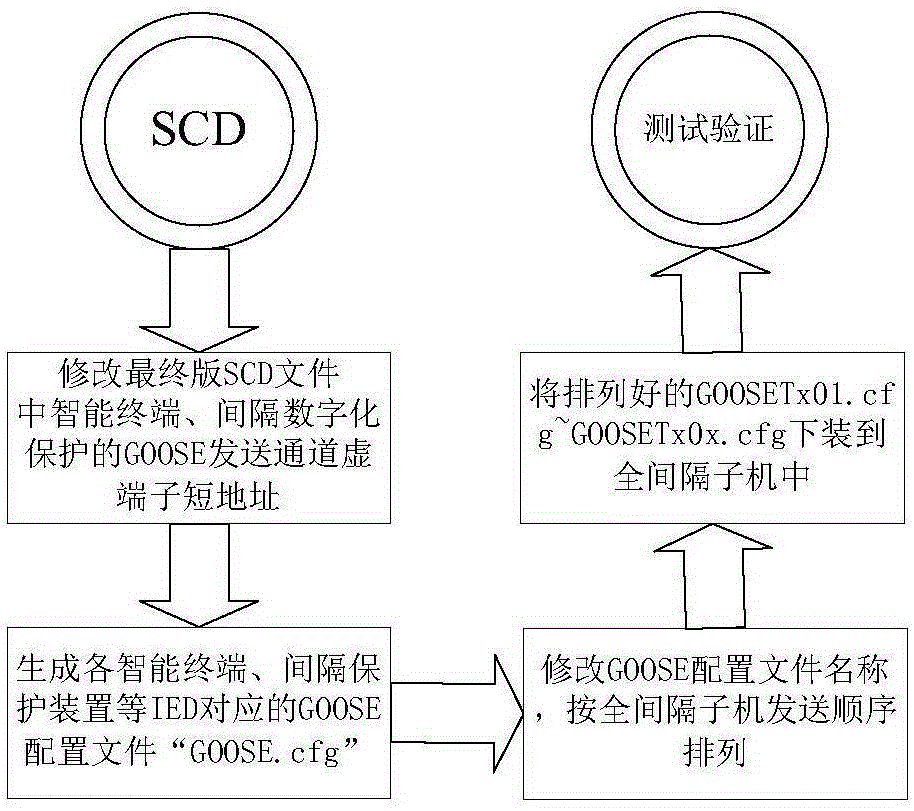

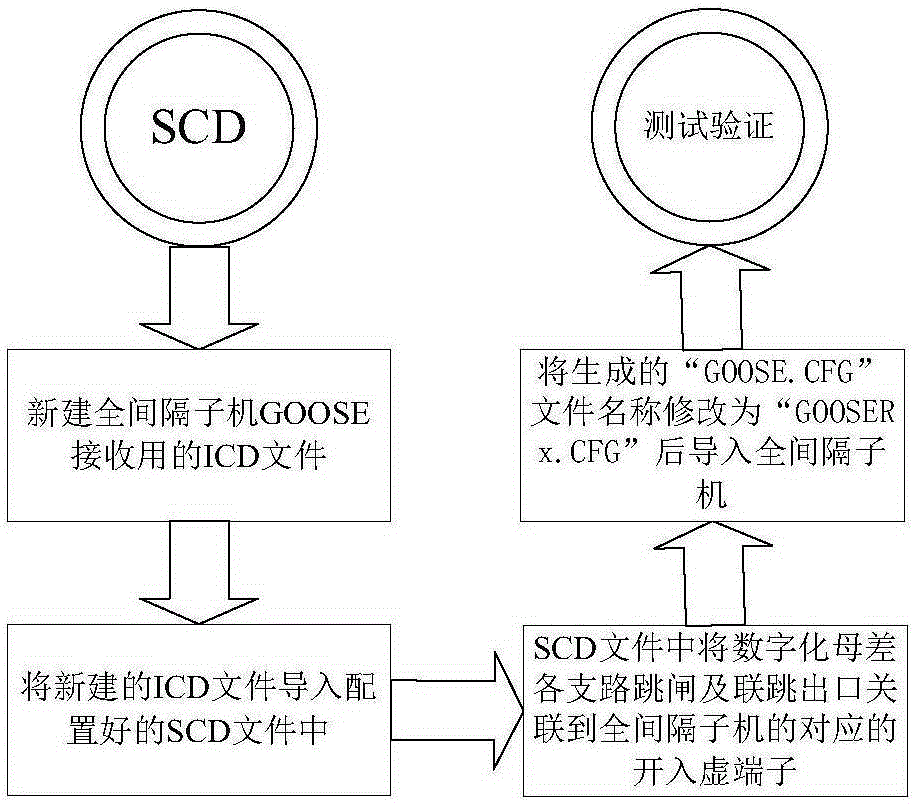

[0022] The embodiment of the present invention provides a method for digital transformation of a substation, specifically a method for seamlessly switching from fully-spaced sub-machines to process-level equipment to connect to the digital bus protection device. The digital bus protection device is put into operation during the transformation, and the digital bus protection before and after the transformation The device configuration remains unchanged, and the original busbar protection device sampling and switching on and off circuits remain unchanged, realizing a smooth transition from conventional substations to digital substations, improving the reliability of relay protection, and ensuring safe opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com