Electrolyte of lithium ion power battery

A power battery and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems that cannot be used alone, and achieve the effects of increasing the dissociation number of the electrolyte, increasing the effective amount of the electrolyte, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

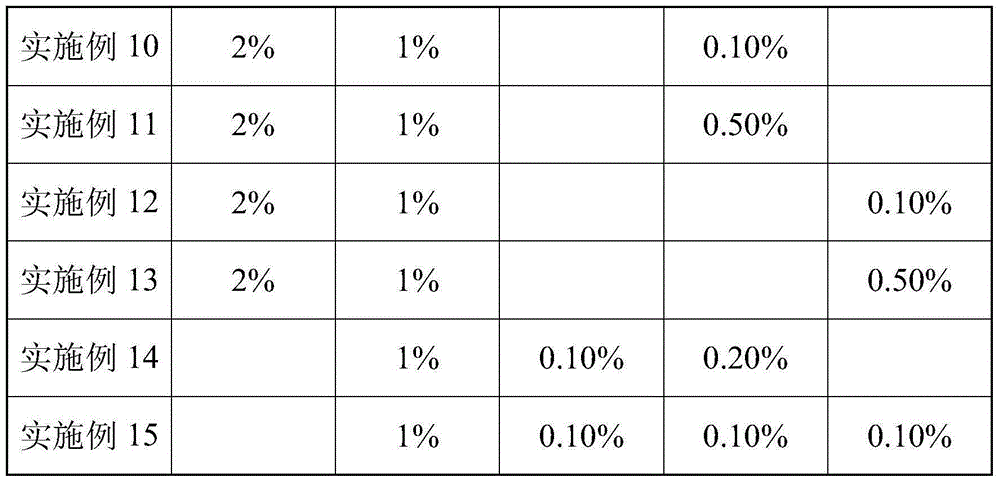

Examples

Embodiment 1

[0026] The electrolyte was prepared in the same way as in Comparative Example 1, except that 0.1% tetraethylammonium tetrafluoroborate was added in addition to this, and lithium tetrafluoroborate was used as the lithium salt with a concentration of 1mol / L.

Embodiment 2

[0028] Electrolyte was prepared according to the same method as in Comparative Example 1, except that 0.5% tetraethylammonium tetrafluoroborate was added on this basis, and lithium bisoxalate borate was used as lithium salt, and the concentration of lithium salt was 1.2mol / L .

Embodiment 3

[0030] Prepare electrolyte solution according to the same method of comparative example 1, difference is to add gross mass 1% tetraethyl ammonium tetrafluoroborate on this basis, adopt lithium difluorooxalate borate as lithium salt, its concentration of lithium salt is 1.2mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com