Blowing system and blowing method for fuel cell

A technology of fuel cells and fuel cell stacks, which is applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve the problems of long purging time and high energy consumption, reduce purging time, reduce energy consumption, and improve reliability Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

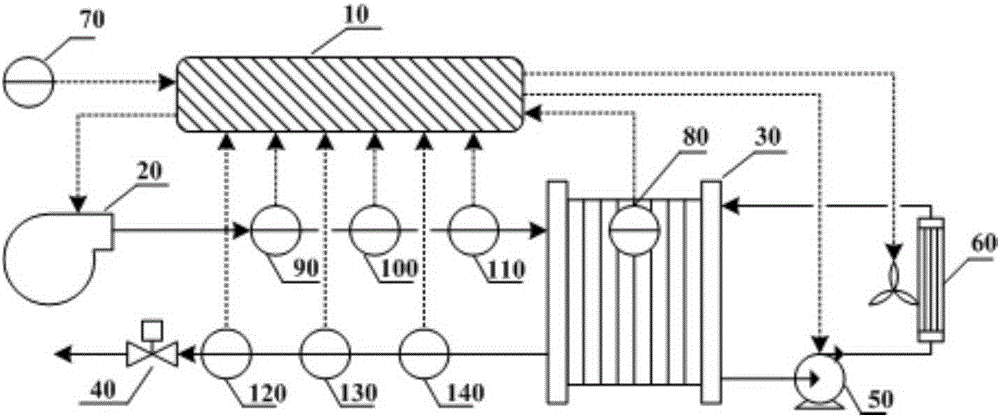

Method used

Image

Examples

Embodiment 1

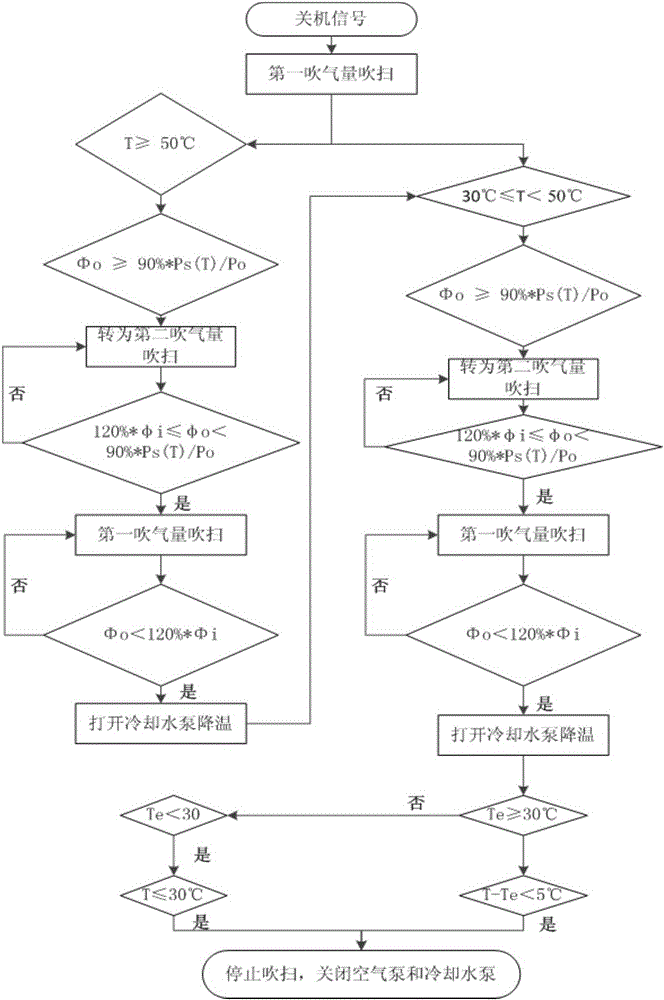

[0056] The purging method of the fuel cell provided in this embodiment is as follows: figure 2 shown, including the following steps:

[0057] 1. After the fuel cell backup power supply system sends a shutdown signal, close the hydrogen intake valve, and the air pump will start to purge the system to meet the first air blowing volume of the rated power of 100w and the speed of 1500RPM, and stop the cooling water pump at the same time. Among them, the first air blowing volume Equal to 1600*P / (F*Vc), P is 50kw, V c It is 0.6v, and F is 96485C / mol.

[0058] 2. Use the battery stack temperature sensor to measure the internal temperature of the fuel cell stack:

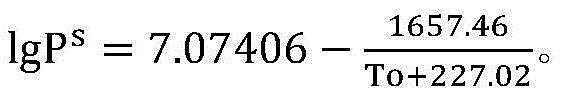

[0059] 2.1. When the internal temperature T of the fuel cell stack is ≥ 50°C, judge the purging method according to the measurement data of the sensor group (outlet temperature sensor, outlet pressure sensor, outlet humidity sensor and inlet humidity sensor):

[0060] a. The humidity of the air flowing out of the fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com